Method and device for generating power through series connection of hydrogen-fired steam turbine and water turbine

A technology of turbogenerators and hydrogenerators, which is applied in the direction of gas turbine devices, wind power generation, machines/engines, etc., can solve the problems of low efficiency of turbogenerators, and achieve the goal of avoiding energy loss and maximizing energy conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

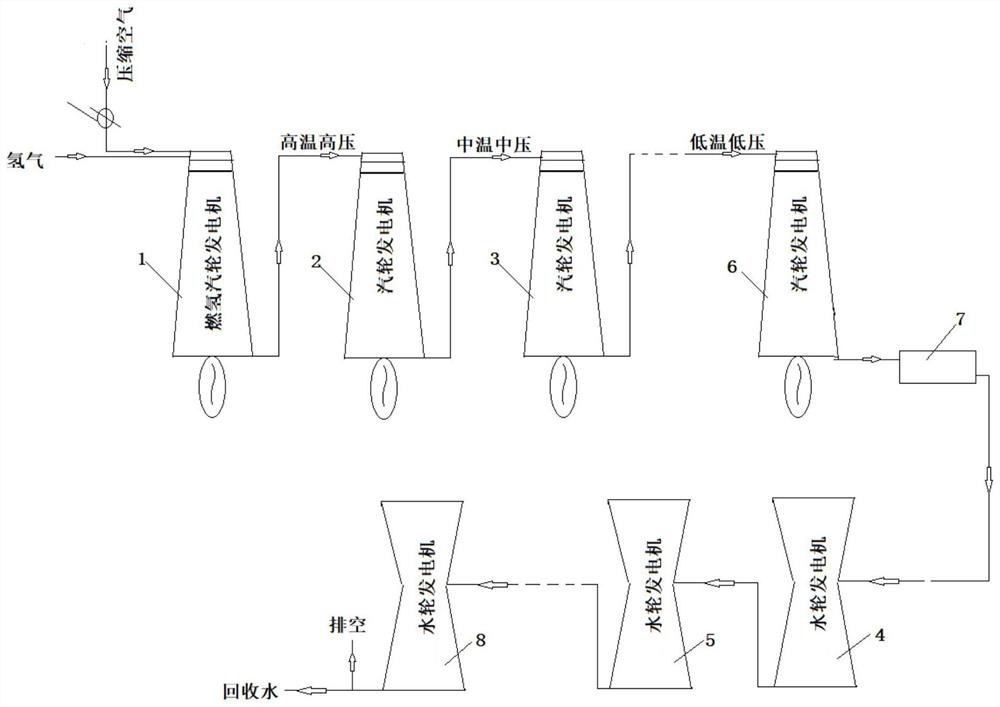

[0024] The present invention provides "a device for generating electricity in series with a hydrogen-fired steam turbine and a water turbine", comprising: a first-stage hydrogen-fired steam turbine generator 1, a second-stage steam turbine generator 2, a third-stage steam turbine generator 3, and a fourth-stage steam turbine A generator 6, an intermediate water vapor regulator 7, a first-stage hydro-generator 4, a second-stage hydro-generator 5, and a third-stage hydro-generator 8 are composed. Among them, the power of the first-stage hydrogen-fired turbine generator 1 is 5000kw / h, the power of the second-stage steam turbine generator 2 is 1000kw / h, the power of the third-stage steam turbine generator 3 is 200kw / h, and the power of the fourth-stage steam turbine is 200kw / h. The power of the generator 6 is 50kw / h, the intermediate water vapor regulator 7, the power of the first-stage hydro-generator 4 is 20kw / h, the power of the second-stage hydro-generator 5 is 10kw / h, and the ...

Embodiment 2

[0026] The present invention provides "a device for generating electricity in series with a hydrogen-fired steam turbine and a water turbine", comprising: a first-stage hydrogen-fired steam turbine generator 1, a second-stage steam turbine generator 2, a third-stage steam turbine generator 3, and a fourth-stage steam turbine A generator 6, an intermediate water vapor regulator 7, a first-stage hydro-generator 4, a second-stage hydro-generator 5, and a third-stage hydro-generator 8 are composed. Among them, the power of the first-stage hydrogen-fired turbine generator 1 is 8000kw / h, the power of the second-stage steam turbine generator 2 is 3000kw / h, the power of the third-stage steam turbine generator 3 is 500kw / h, and the power of the fourth-stage steam turbine is 500kw / h. The power of the generator 6 is 100kw / h, the intermediate water vapor regulator 7, the power of the first-stage hydro-generator 4 is 50kw / h, the power of the second-stage hydro-generator 5 is 30kw / h, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com