Glassware liner airtightness detection device and implementation method thereof

A technology of air tightness detection and glassware, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, glass production, and by measuring the increase and deceleration rate of fluid, etc. It can solve the problem of glassware gas leakage, easy contamination of water vapor, and the impact of Inspectors' observation of equipment operation and other issues, to reduce detection errors and improve air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

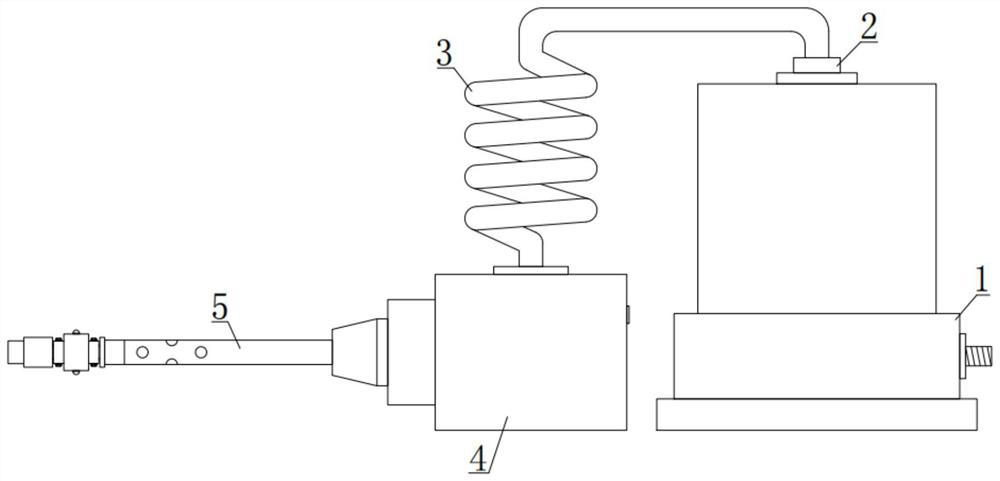

[0040] In order to better demonstrate the implementation process of the glassware liner air tightness detection device, this embodiment now proposes an implementation method of the glassware liner gas tightness detection device, including the following steps:

[0041] Step 1: Insert the airtightness detection component 5 into the inner container of the glassware, and use the plug 52 to cooperate with the sealing gasket 513 to complete the complete sealing of the inner container of the glassware;

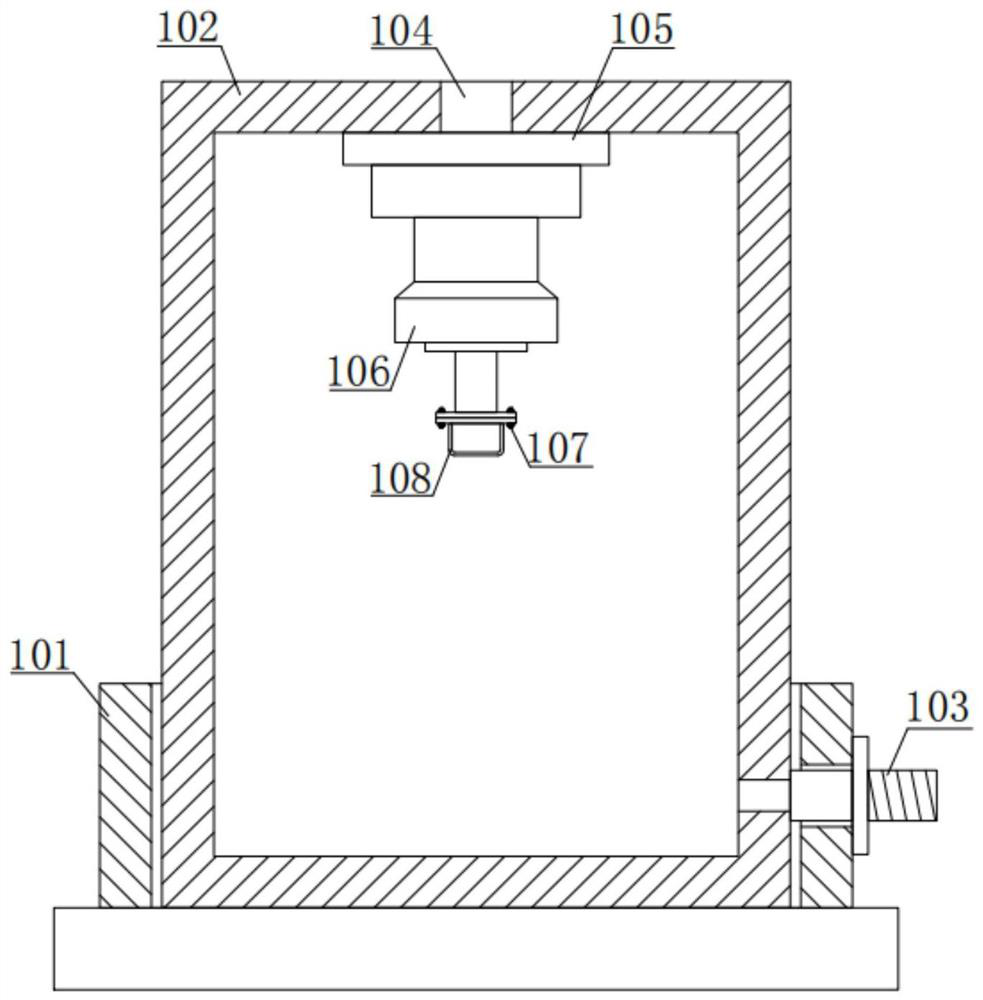

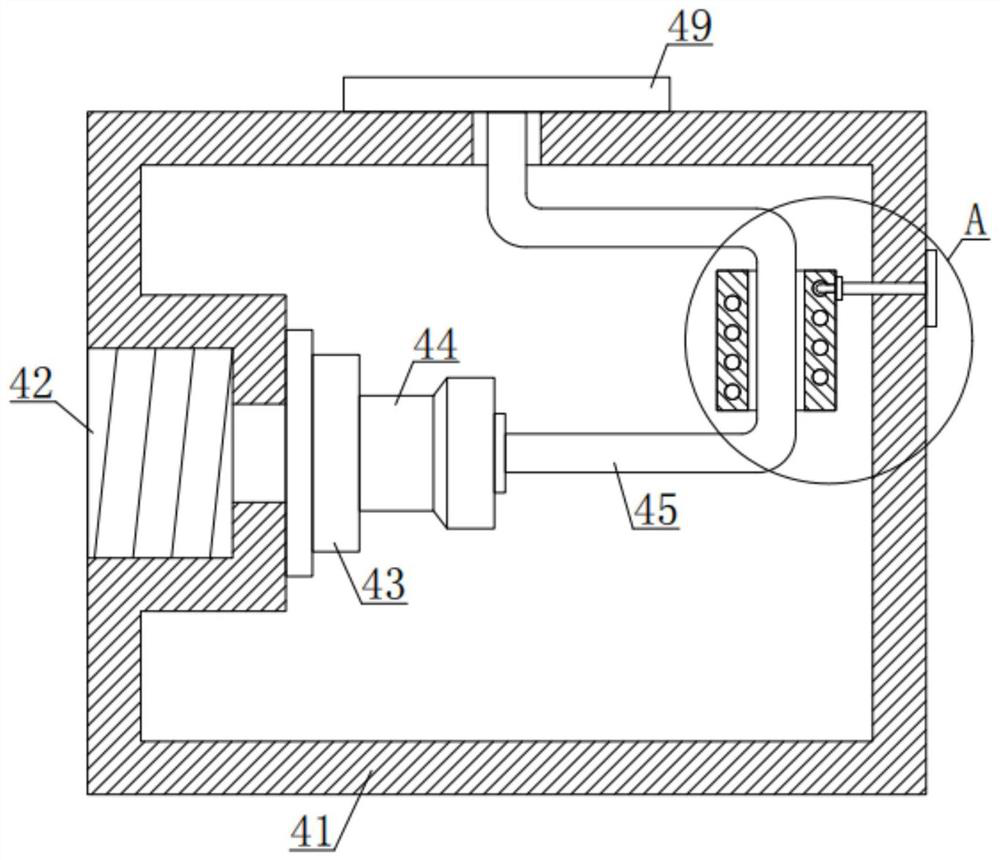

[0042] Step 2: The gas in the box shell 102 is extracted by the air blowing pump 106, and is transported to the transfer box 4 through the elastic connecting pipe 3. When transported in the transport pipe 45 in the transfer box 4, the heating coil in the heating ferrule 46 can be used. 47 for heating;

[0043] Step 3: The gas is transported to the air tightness detection assembly 5 through the delivery pump 44, and is blown out through the air outlet 54, and the air pressure test is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com