Solid rocket engine jet pipe material parameter sensitivity calculation method

A technology for engine nozzles and solid rockets, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve the problem of few global sensitivity analysis methods, simplify the process of sensitivity analysis, reduce the amount of calculation, and improve analysis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below with reference to the accompanying drawings and specific analysis cases.

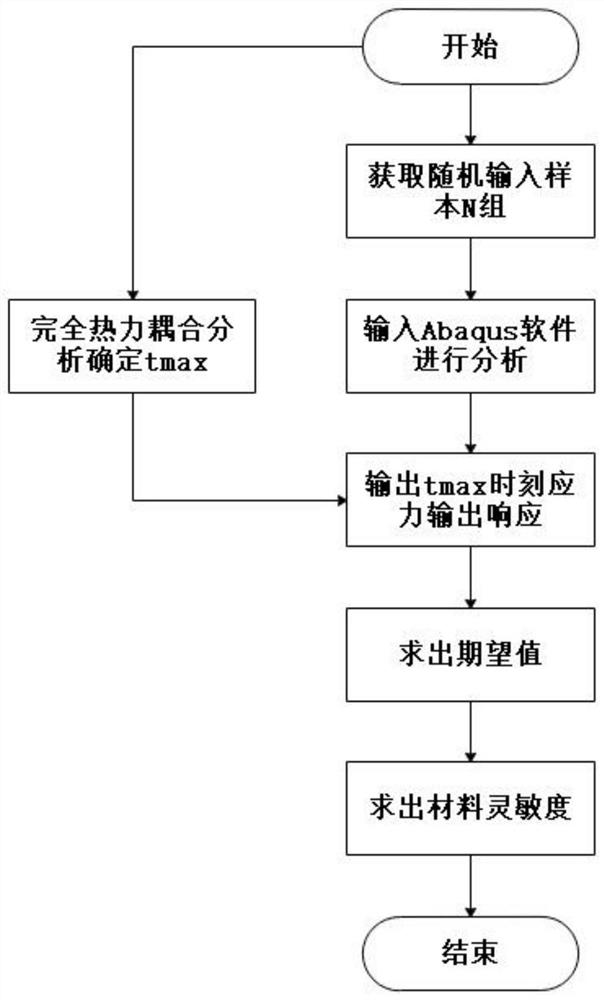

[0050] In this embodiment, a method for calculating the sensitivity of the material parameters of a solid rocket motor nozzle, such as figure 1 shown, including:

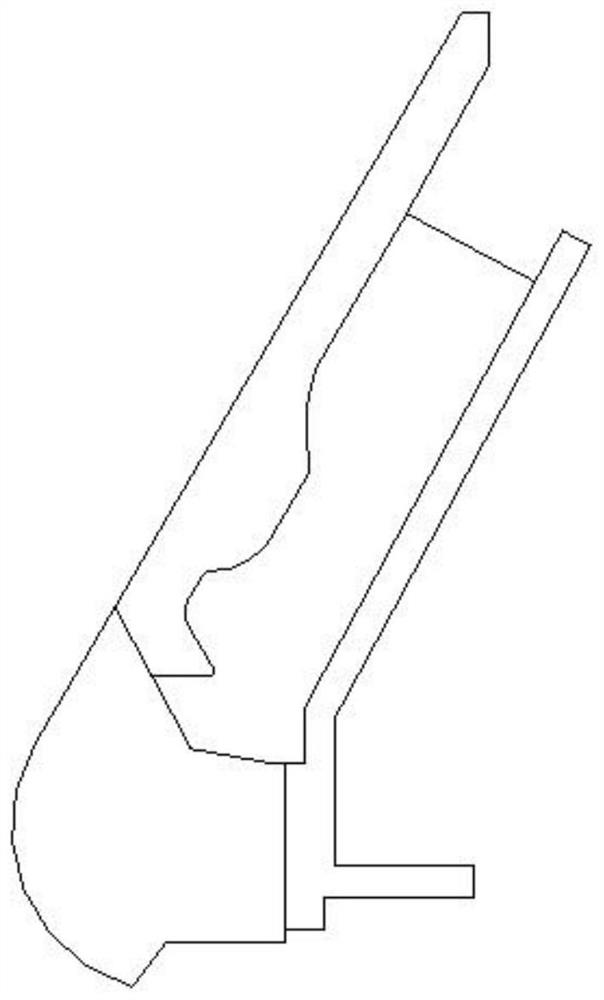

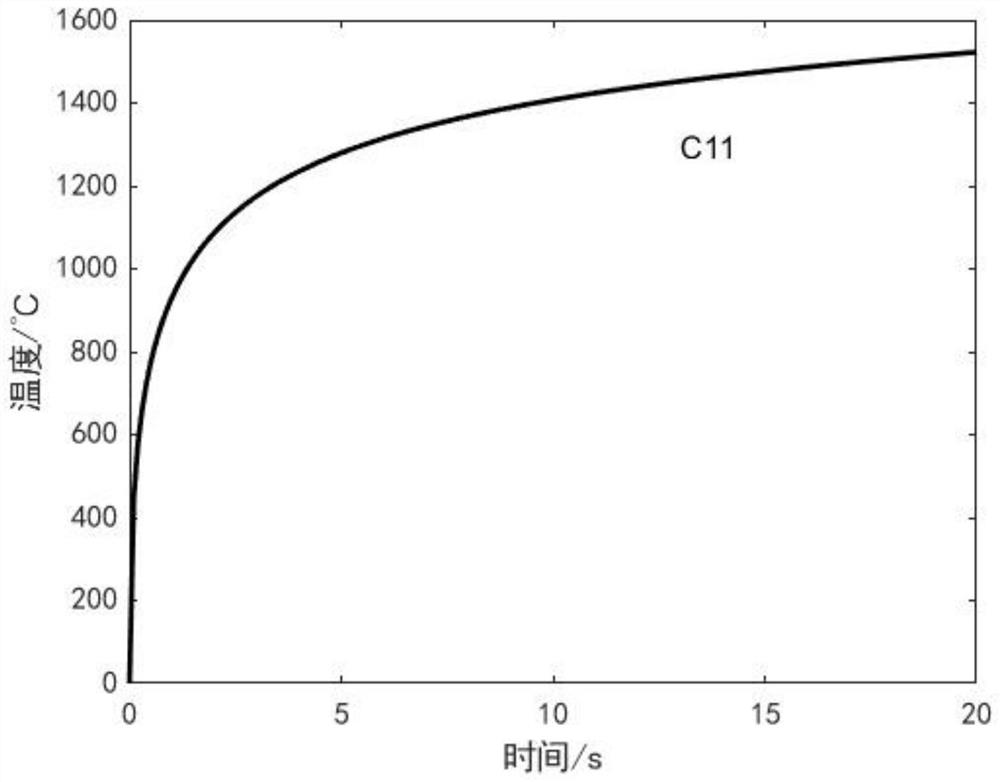

[0051] First, the axisymmetric section of the solid rocket motor nozzle is intercepted to build a simulation model. The model is as follows figure 2 As shown, Abaqus / Standard software is used for finite element simulation of the model. The specific operations include: setting material properties in the property module; meshing the model in the mesh module, and the selected mesh element is CAX4T; in the loading module, imposing boundary condition constraints on the model, including the model shell Perform fixed constraints and apply discrete pressure fields to the inner wall of the model; in the interaction module, apply discrete temperature fields and convective heat transfer coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com