Calibration method and execution method of shot peening forming part

A technology of shot peening and calibration method, which is applied in the direction of process efficiency improvement, geometric CAD, design optimization/simulation, etc., and can solve problems such as poor working environment, low unit output, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the present invention.

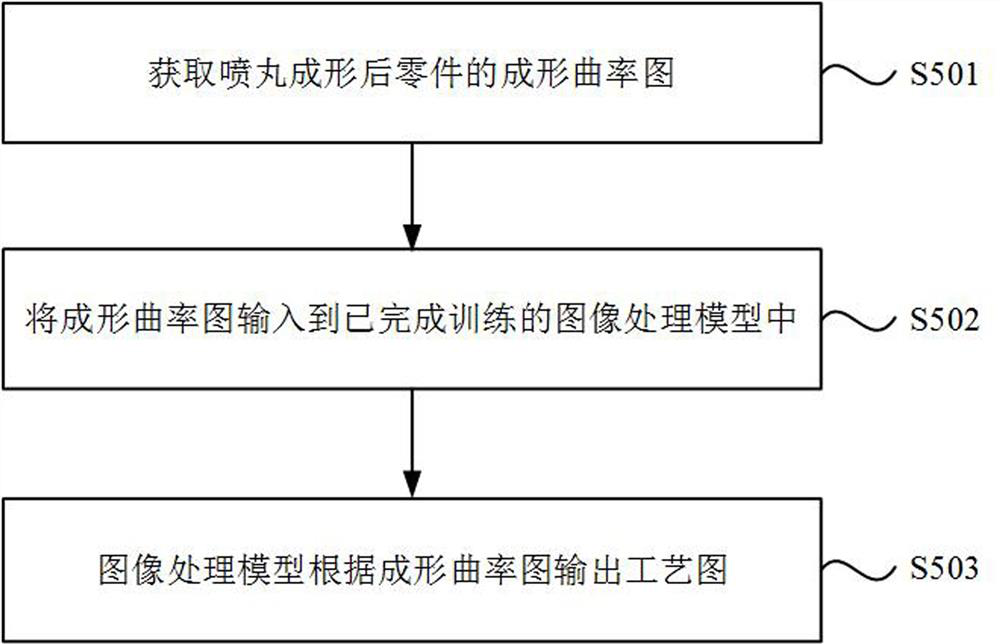

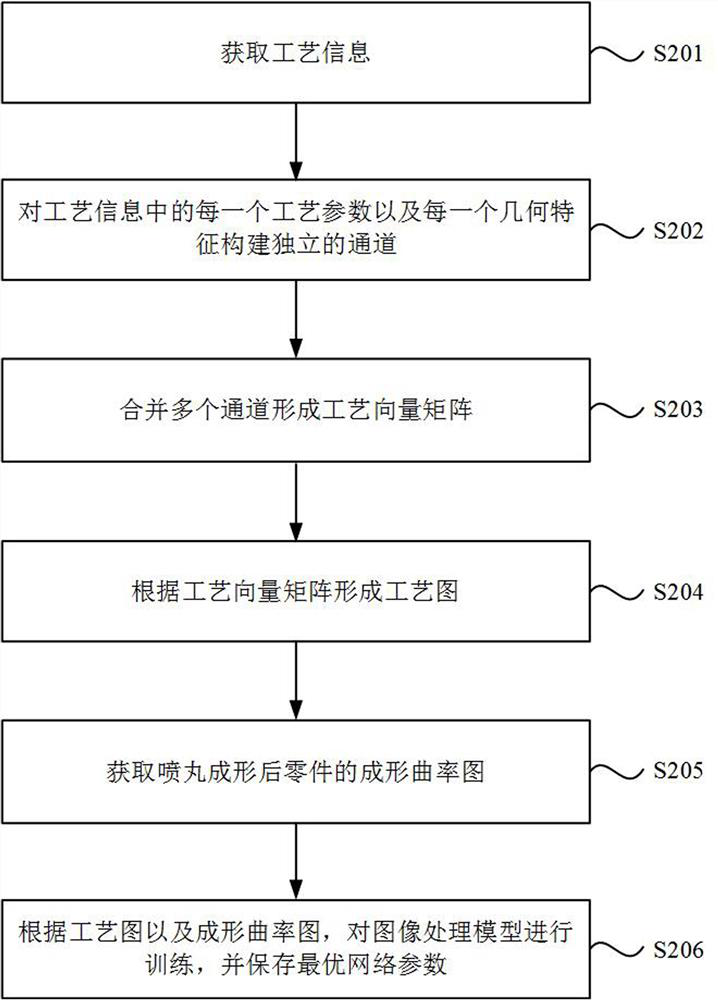

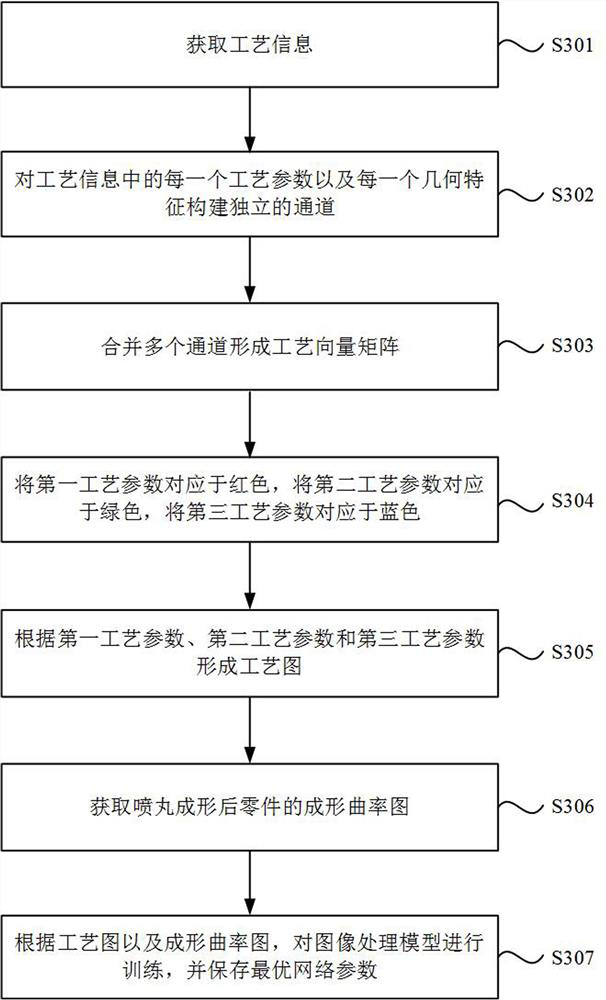

[0063] In order to overcome the problem of prediction by the finite element method, a calibration method and execution method of shot peening parts are proposed. Based on the deep learning algorithm, the method further introduces the shot peening process data and workpiece geometry features to realize the shot peening curvature. rapid prediction and process reverse design. In addition, according to the characteristics of shot peening prediction, the traditional deep learning model was introduced into the attention mechanism and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com