Filter screen assembly and drainage device

A filter and component technology, applied in aircraft accessories, filtration separation, fixed filter element filters, etc., can solve problems such as easy damage and limitation of filter performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0070] figure 1 It is a schematic diagram showing the position of the door of the aircraft. like figure 1 As shown, the aircraft cabin doors are mainly divided into three types: a boarding door 100 , a service door 200 , and an emergency door 300 . In the present embodiment, the drainage structure at the boarding gate 100 will be described as an example.

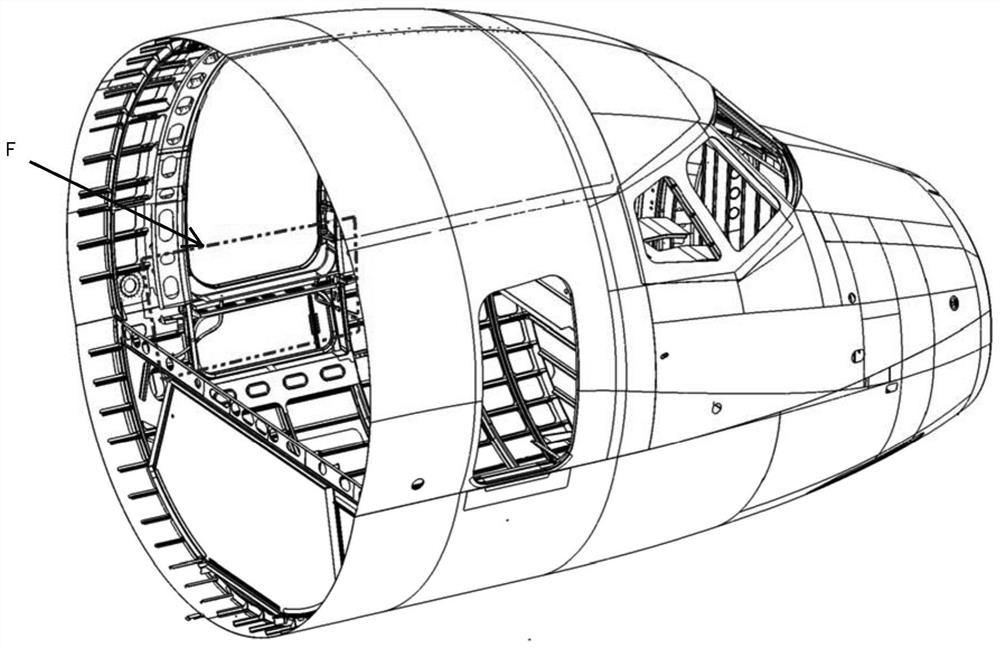

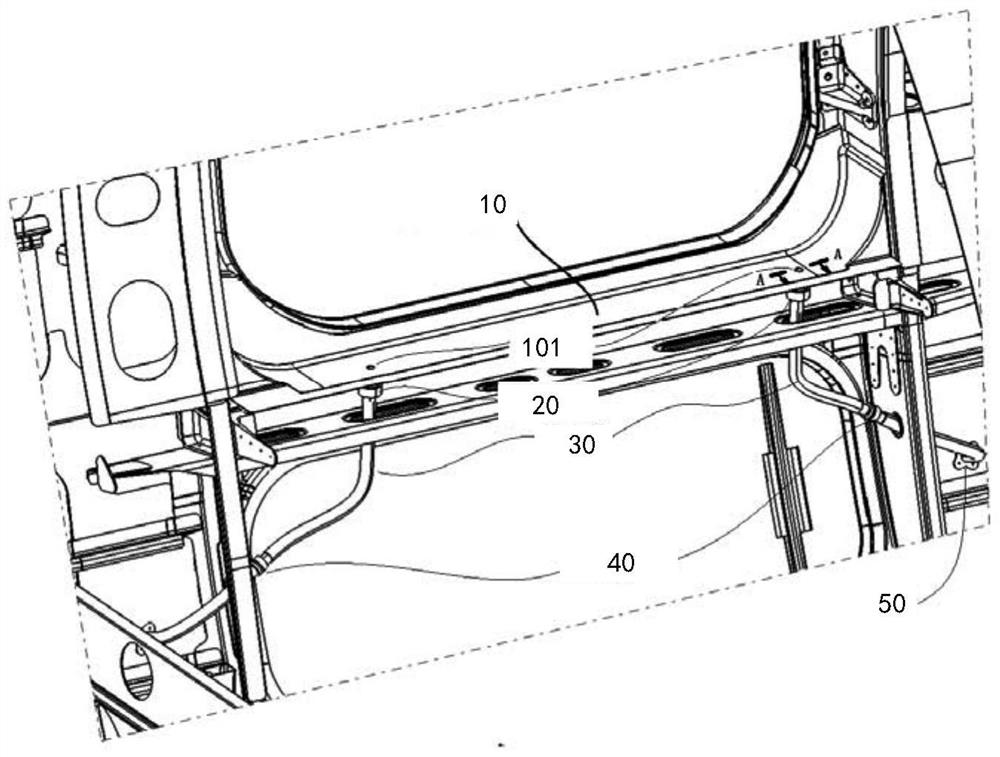

[0071] figure 2 is a perspective view of the nose section, image 3 is a partial enlarged view showing the drainage structure of the boarding gate, yes figure 2 Enlarged view of section F. like image 3 As shown, the drainage device 1 includes a sill sump 10, a filter screen assembly 20, a drainage pipe 30, a one-way valve 40, a flange joint 50, and the like. The door sill water pan 10 is provided on the floor of the hatch. The filter screen assembly 20 and the one-way valve 40 and the one-way valve 40 and the flange joint 50 are connected by hoses. The flange joint 50 is connected with the fuselage skin through r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap