Automatic welding method and device for end of round drill rod

An automatic welding and drill pipe technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of untraceable welding quality, harsh manual operating environment, loss of parameter records, etc., to achieve stable and reliable production quality, artificial Small influence of factors and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Below in conjunction with accompanying drawing, structure principle and working principle of the present invention are described in detail:

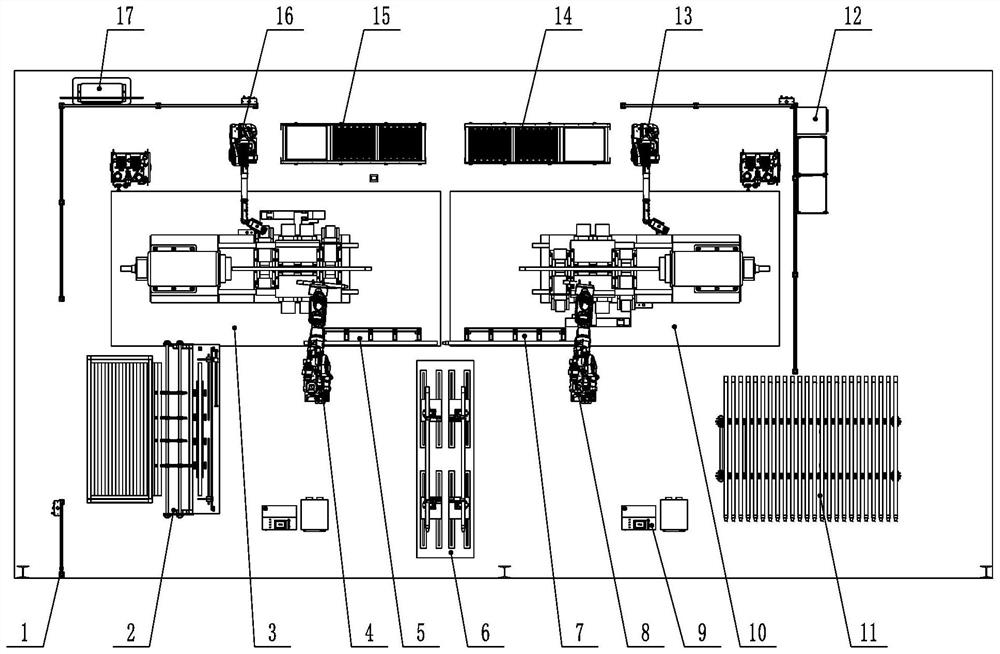

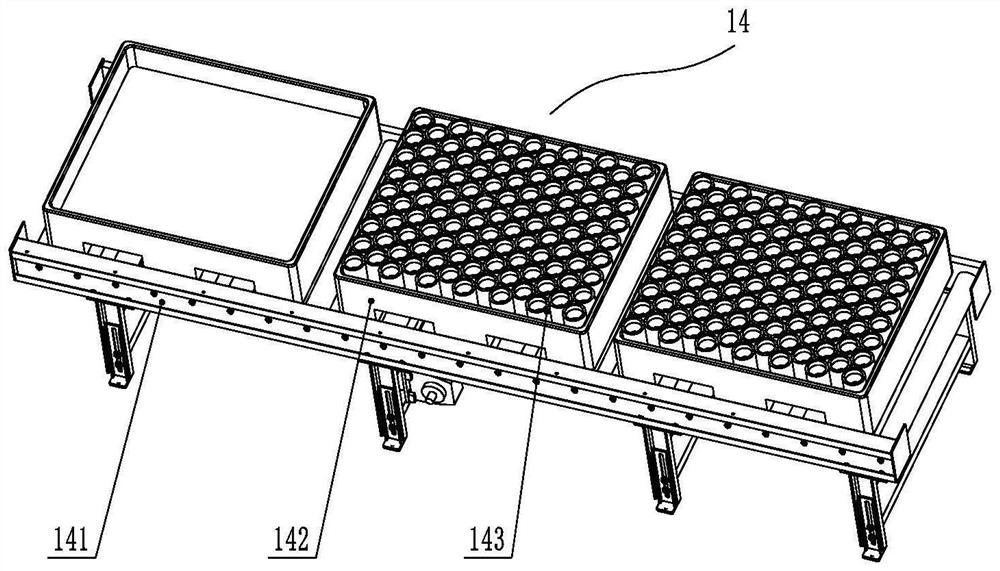

[0092] see figure 2 , figure 2 It is a schematic structural diagram of an apparatus according to an embodiment of the present invention. The automatic welding device for round drill pipe ends of the present invention includes: a male friction welding machine 3; The head friction welding machine 10 is a continuous friction welding machine; the pipe body transfer robot 4 is arranged on one side of the male head friction welding machine 3, and a pipe body buffer material rack 5 is correspondingly provided on one side of the pipe body transfer robot 4; The male head transfer robot 16 is arranged on the other side of the male head friction welding machine 3, one side of the male head transfer robot 16 is provided with a male head feeding line 15, and a male head feeding line 15 is provided with a The code recognition camera 154 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com