Cooling device for stainless steel welding

A cooling device, stainless steel technology, applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of cooling liquid temperature rise, easy residual water marks, poor drying uniformity, etc., and achieve the effect of rapid heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

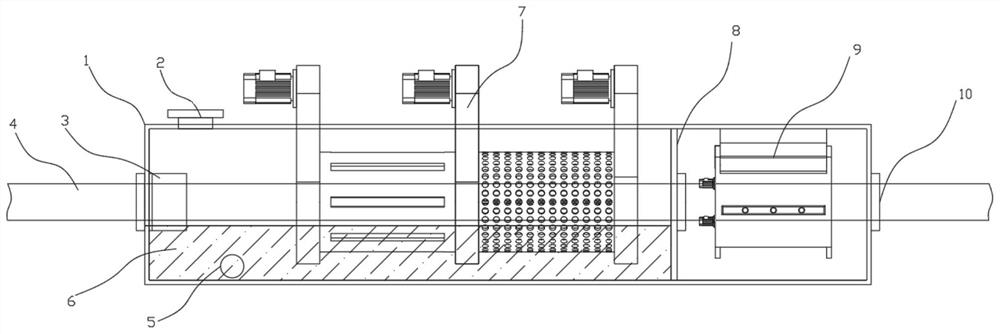

[0037] see figure 1 , the present invention provides a cooling device for stainless steel welding, comprising a cooling box 1, a water injection pipe 2 is installed at the left end of the top of the cooling box 1, and an introduction head 3 and an outlet head 10 are embedded in the middle of the left and right ends of the cooling box 1, respectively. 3. A stainless steel pipe 4 penetrates into the middle of the cooling box 1 and then extends out from the middle of the lead-out head 10. The lower end of the back of the cooling box 1 is provided with a water outlet 5, the right end of the cooling box 1 is divided into two by the partition plate 8, and the left end is a cooling cavity. The right end is the drying cavity, the middle of the partition 8 is sealed by the stainless steel tube 4, and the cooling liquid 6 is injected into the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap