Continuous graphitization furnace and production system for lithium battery negative electrode material

A graphitization furnace and negative electrode material technology, which is applied to electrochemical generators, battery electrodes, circuits, etc., can solve problems such as time-consuming and laborious, long and narrow graphitization furnace, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

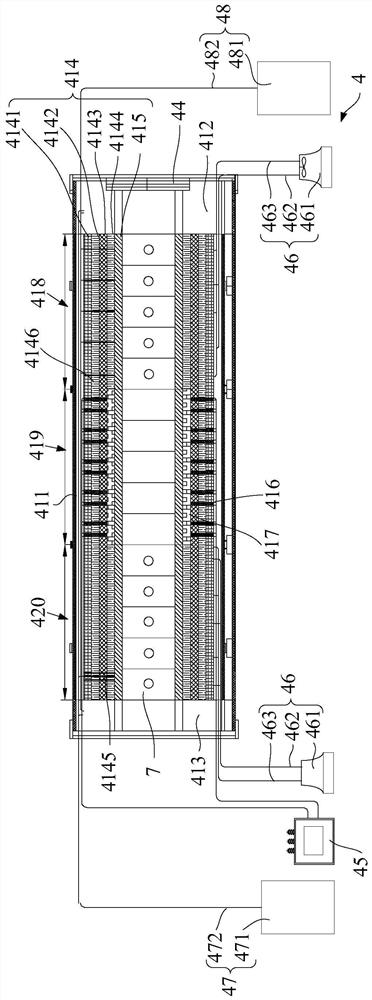

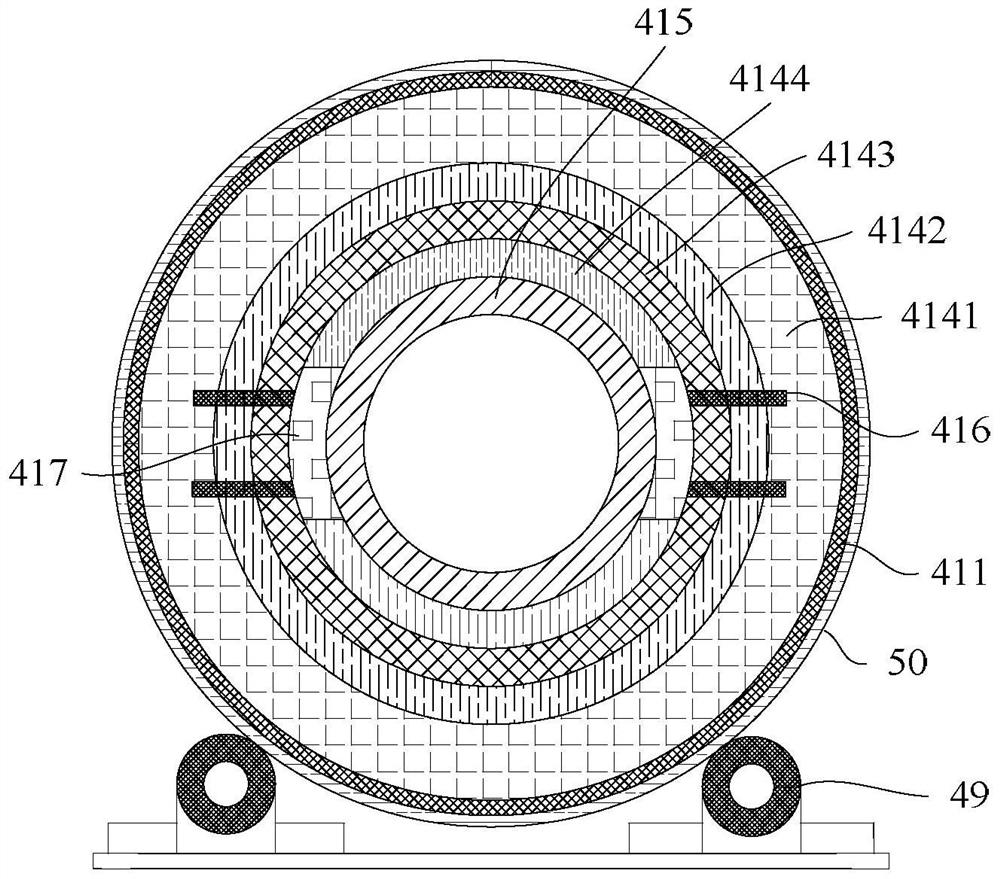

[0048] see image 3 As shown, the embodiment of the present application provides a continuous graphitization furnace 4 of a lithium battery negative electrode material, including: a graphitization furnace body 41, a rotating support seat 42 and a first pushing device 43; wherein, the rotating support seat 42 uses is arranged on the working surface, and the graphitization furnace body 41 is rotatably connected with the rotating support seat 42;

[0049] The first pushing device 43 is connected with the graphitization furnace, and is used for driving the graphitization furnace to rotate relative to the rotating support base 42 .

[0050] Based on the structure described above, during the use of the continuous graphitization furnace 4 of the lithium battery negative electrode material provided by the present application, the first pushing device 43 drives the graphitization furnace body 41 to rotate around the rotating support base 42, thereby making the graphitization furnace T...

Embodiment 2

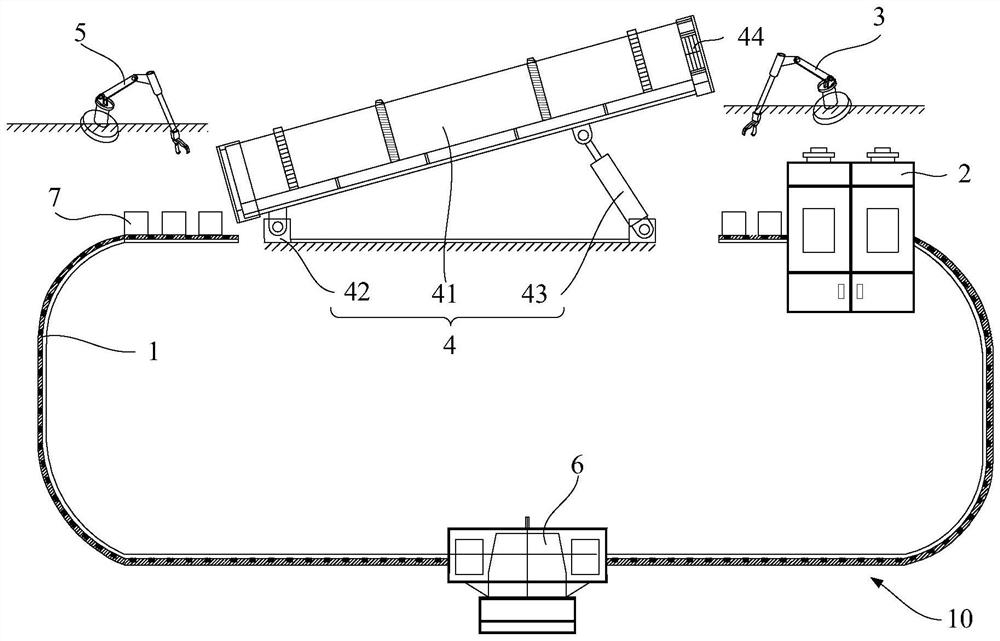

[0105] see image 3 As shown, the second embodiment of the present application also provides a continuous graphitization production system 10 for a lithium battery negative electrode material, including the continuous graphitization furnace 4 for the lithium battery negative electrode material described in the above-mentioned first embodiment, and therefore, has the lithium battery negative electrode material. All the beneficial technical effects of the continuous graphitization furnace 4 of the material, the same technical features and beneficial effects will not be repeated.

[0106] In this embodiment, preferably, as Figure 1 to Figure 3 As shown, the continuous graphitization production system 10 of the negative electrode material for lithium batteries also includes a circulation track 1, a charging device 2, a feeding device 3, a taking-out device 5 and a discharging device 6;

[0107] Wherein, the circulation track 1 extends along the outlet end of the graphitization f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com