Impeller structure of washing machine

A washing machine and pulsator technology, applied in the field of washing machines, can solve problems such as affecting the safety of clothing and human health, increase labor, and be difficult to clean, so as to ensure the safety of clothing and human health, reduce the probability of clothing damage, and improve the experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

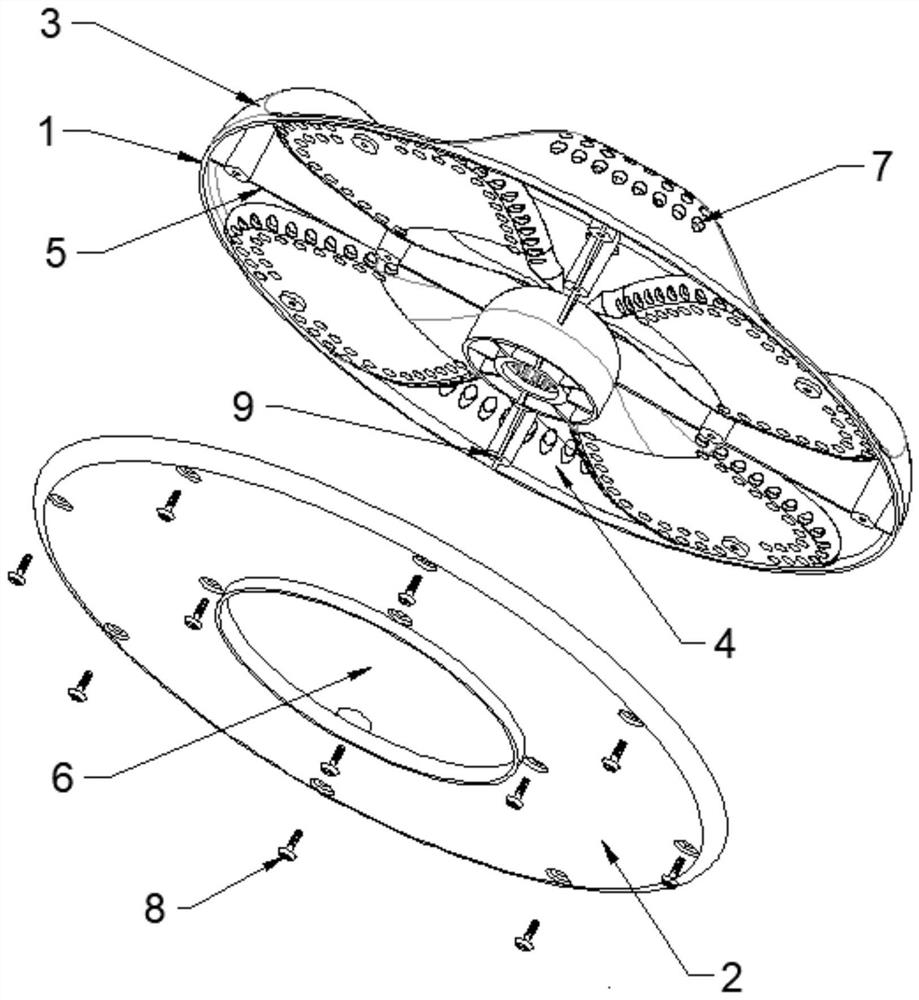

[0023] like figure 1 and Figure 5 As shown, a washing machine pulsator structure includes a disc-shaped pulsator panel 1, and four stirring ridges 3 are fixed radially on the front of the pulsator panel. An upright water guide vane 5 is fixed in the center along its length direction in the groove 4, the back side of the pulsator panel is buckled with the pulsator back plate 2, and the pulsator back plate and the pulsator panel are arranged between the pulsator back plate and the pulsator panel. A water guide cavity is formed by interlocking with each other. The center of the pulsator back plate is provided with a water inlet 6, and the front of the pulsator panel is provided with a number of water outlet holes 7. The water inlet and each of the water outlet holes are the same as the The water guide cavity is connected.

[0024] The pulsator back plate is fixedly connected to the pulsator panel through a plurality of mounting screws 8, and the back of the pulsator panel is f...

Embodiment 2

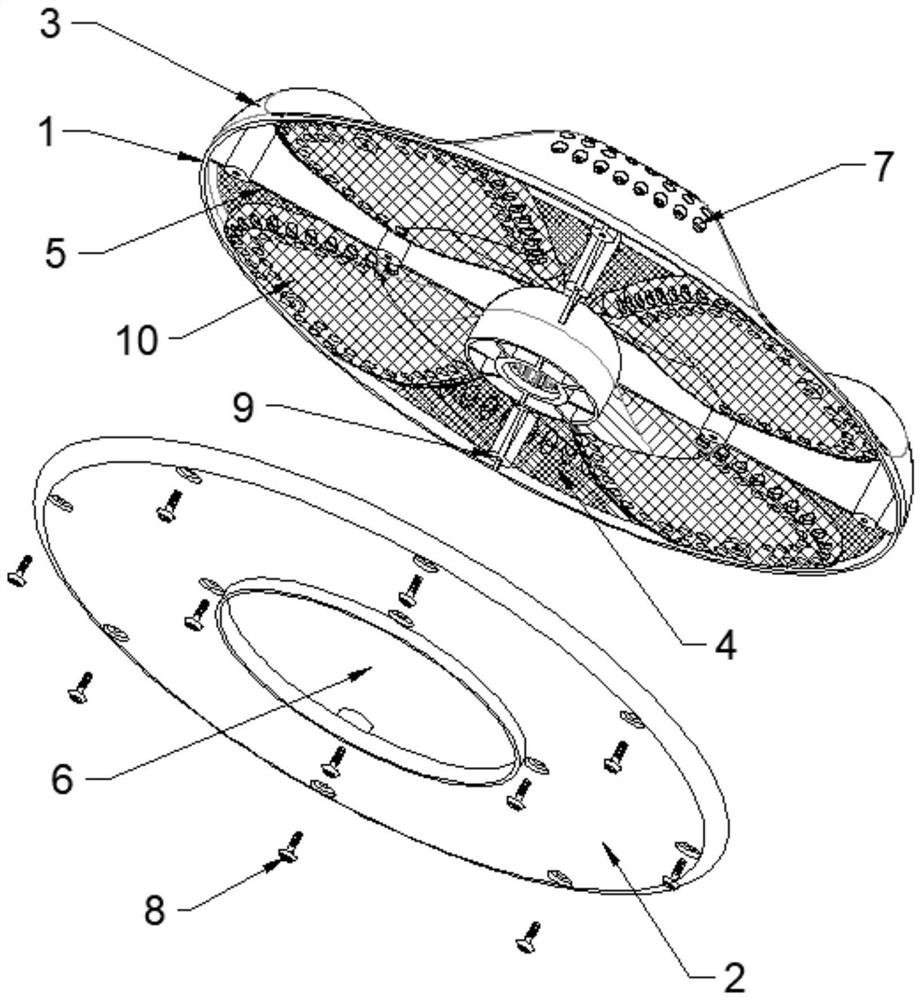

[0028] like figure 2 and Figure 5 As shown, a washing machine pulsator structure includes a disc-shaped pulsator panel 1, and four stirring ridges 3 are fixed radially on the front of the pulsator panel. An upright water guide vane 5 is fixed in the groove 4 along its length direction, the back side of the pulsator panel is buckled with the pulsator back panel 2, and the pulsator back panel and the pulsator panel are mutually connected. Buckle to form a water guide cavity, the center of the pulsator back plate is provided with a water inlet 6, and the front of the pulsator panel is provided with a number of water outlet holes 7, the water inlet and each of the water outlet holes are connected with the water guide The water chamber is connected.

[0029] The inner side of each water outlet is provided with a filter screen 10, and the filter screen is a layer of filter screen laid integrally on the uneven back surface of the pulsator panel (ie, the water inlet side of each w...

Embodiment 3

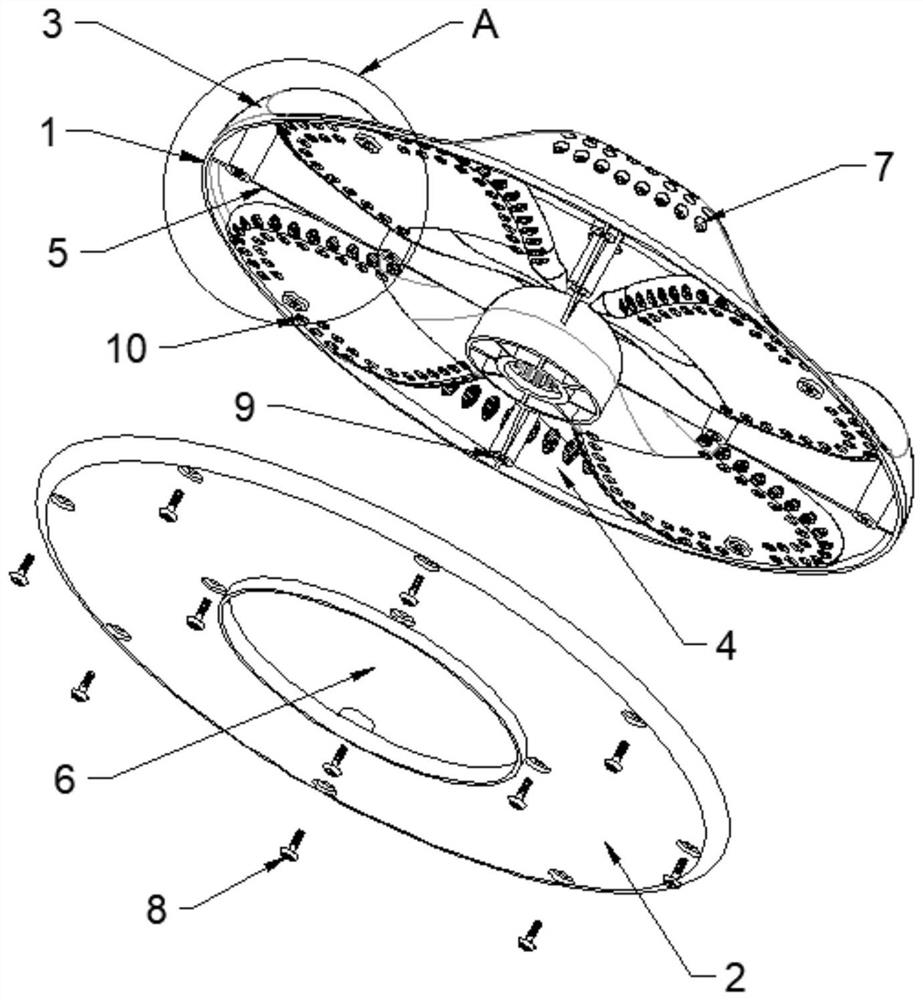

[0034] like Figure 3-5 As shown, a washing machine pulsator structure includes a disc-shaped pulsator panel 1, and four stirring ridges 3 are fixed radially on the front of the pulsator panel. An upright water guide vane 5 is centrally fixed in the groove 4 along its length direction. The back side of the pulsator panel is buckled and provided with a disc-shaped pulsator back plate 2. The pulsator back plate is connected to the pulsator. The panels are buckled with each other to form a water guide cavity, the center of the pulsator back plate is provided with a water inlet 6, and the front of the pulsator panel is provided with a number of water outlet holes 7, the water inlet and each of the water outlet holes are communicated with the water guide cavity.

[0035] A filter screen 10 is arranged inside each of the water outlet holes, and the filter screen is a small filter screen separately arranged in each of the water outlet holes, and each filter screen is integrally cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com