Double-rib type longitudinal rib and bridge deck structure

A longitudinal rib and integrated technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as poor fatigue resistance, achieve excellent longitudinal force transmission performance, extend longitudinal bridge stress influence lines, and diversify connection methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

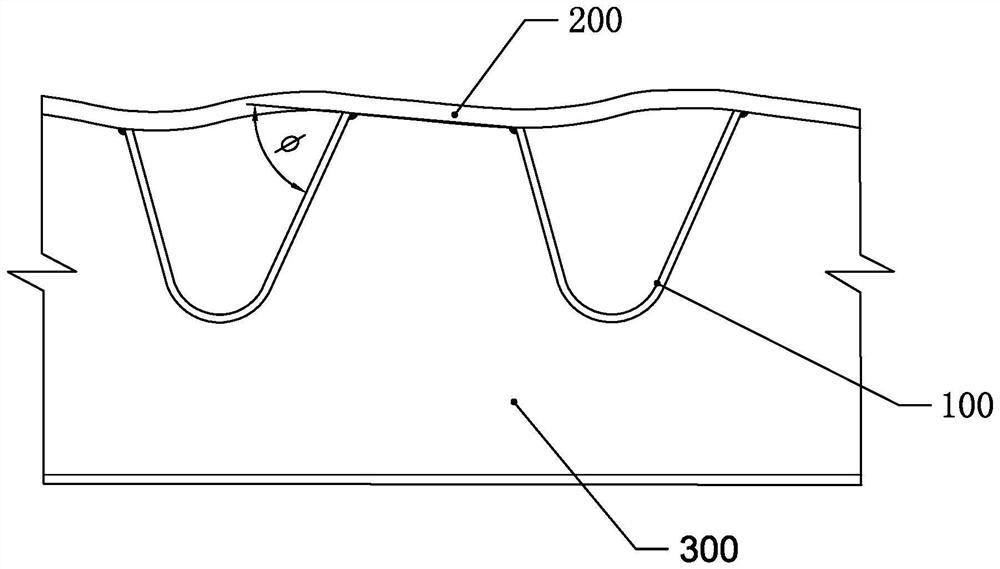

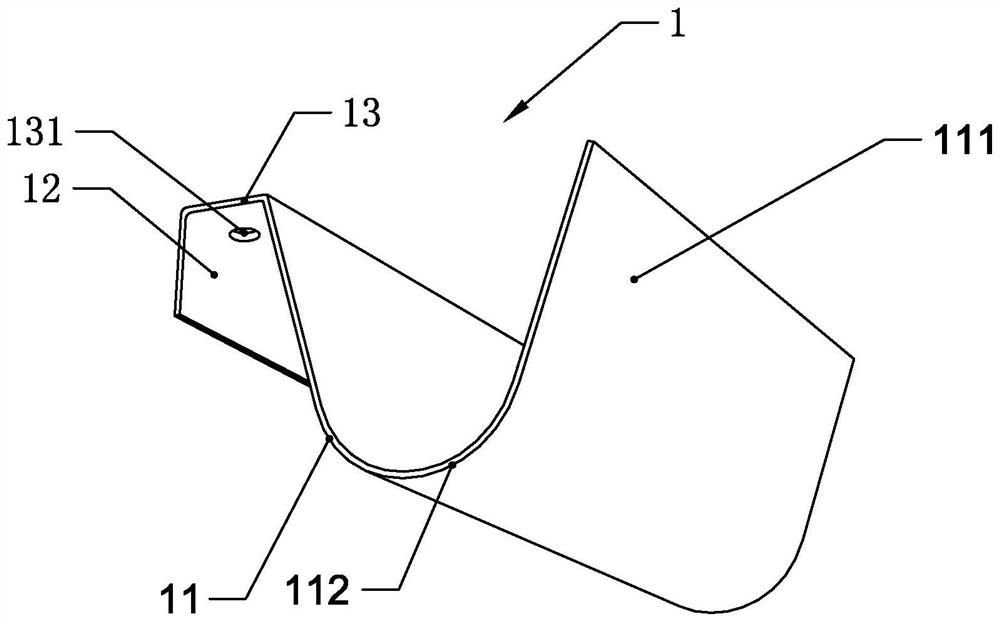

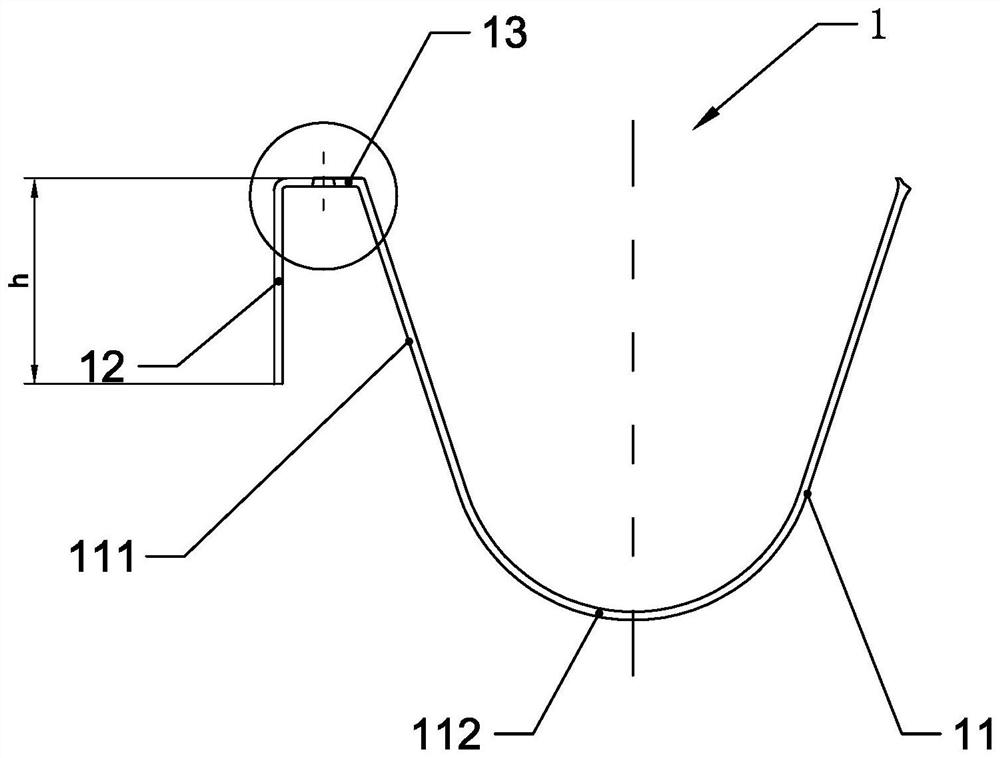

[0044] like figure 2 , 3 As shown, Embodiment 1 of the present application is a double-rib type longitudinal rib 1 , which includes a closed rib 11 , an open rib 12 and an ear plate 13 , and the closed rib 11 and the open rib 12 are connected by the lug plate 13 . The closing rib 11 includes a pair of symmetrical side webs 111 and a bottom edge 112 connecting the lower ends of the pair of side webs 111 . The upper end of the side web 111 on one side of the closed rib 11 has an outwardly folded ear plate 13. One end of the ear plate 13 is connected to the upper end of the side web 111, and the other end is connected to the upper end of the open rib 12. The ear plate 13 is along the length of the longitudinal rib 1. A plurality of connection holes 131 are opened in the direction. like Figure 4 As shown, the ear plate 13 and the side web plate 111 have a first rotation angle α, and 90°≤α≤135°, the opening rib 12 is formed by folding the outer end of the ear plate 13, and the...

Embodiment 2

[0052] like Figure 7 , 8 As shown, Embodiment 2 of the present application provides another double-ribbed longitudinal rib 1 of a bridge deck structure. The difference from Embodiment 1 is that both sides of the closed rib 11 of the longitudinal rib 1 are provided with lugs 13 and open ribs 12. .

[0053] Under the premise of not increasing the amount of welding, in the second embodiment of the present application, the two side webs 111 of the closed rib 11 are continuously bent twice to form the ear plate 13 and the open rib 12, which is equivalent to the two sides of the closed longitudinal rib 1. Two open ribs are added on the side, which significantly improves its longitudinal bending and torsional rigidity, prolongs the longitudinal stress influence line of the longitudinal bridge, and makes the longitudinal force transmission performance of longitudinal rib 1 better.

[0054] Using the bridge deck structure of the longitudinal ribs 1, since the side webs 111 on the ad...

Embodiment 3

[0057] like Figure 10 As shown, Embodiment 3 of the present application provides a case where a double-rib longitudinal rib 1 is used for a composite structural bridge deck. The closed rib 11 has a trapezoidal cross-section, the open rib 12 has a lower flange 121, and the lower flange 121 is formed by folding the lower end of the open rib 12. The setting of the lower flange 121 further increases the cross-sectional moment of inertia of the open rib 12, thereby increasing the open rib 12 bending and torsion resistance. The upper surface of the top plate 2 is laid with a reinforced concrete layer, and the connecting hole 131 of the lug plate 13 is provided with a connecting piece 3. The connecting piece 3 is a high-strength bolt, which is connected with the top plate 2 by bolt connection. Concrete anchoring, especially suitable for steel-concrete composite deck structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com