Operation control method and control device for cold storage equipment and cold storage equipment

A technology for operation control and cold storage, applied in household refrigeration devices, lighting and heating equipment, applications, etc., can solve problems such as the system no longer running normally, the temperature in the box rises, and the deterioration of items fails, so as to reduce the risk of deterioration and avoid Shutdown protection, guaranteed effect of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

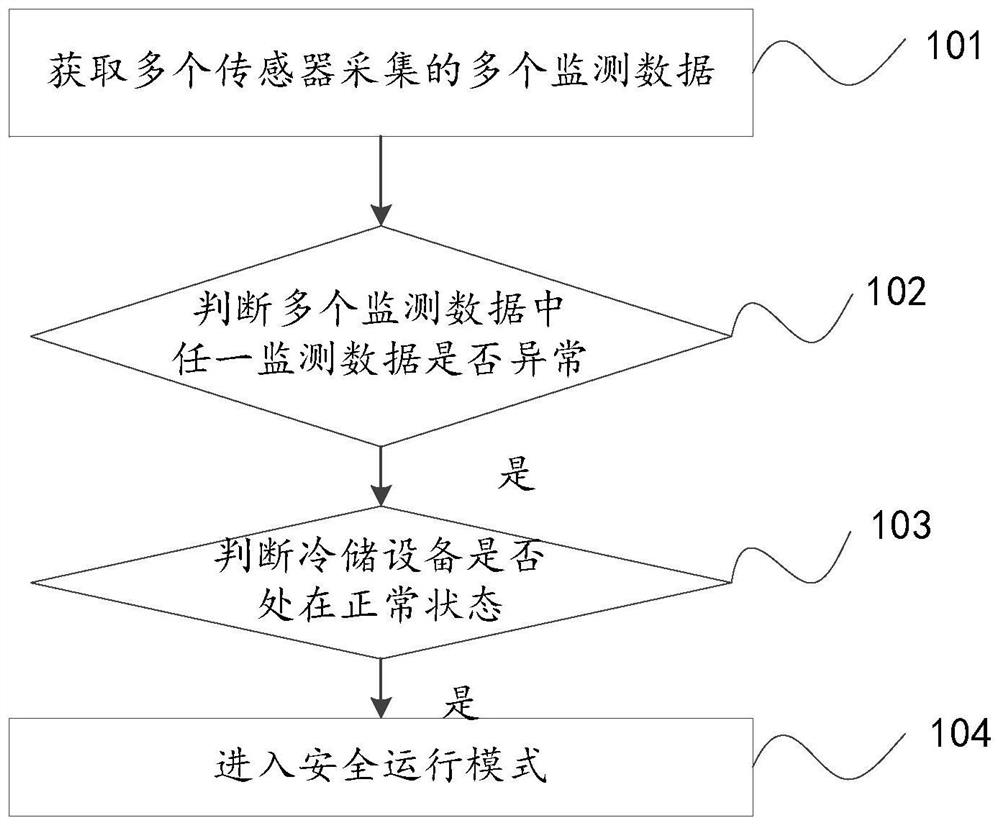

[0031] figure 1 One of the schematic flow charts of the operation control method according to the embodiment of the present invention is shown. like figure 1 As shown, the operation control method includes:

[0032] Step 101, acquiring multiple monitoring data collected by multiple sensors;

[0033] Step 102, determine whether any monitoring data in the plurality of monitoring data is abnormal; when it is determined that any monitoring data is abnormal, perform step 103;

[0034] Step 103, determine whether the cold storage device is in a normal state; if so, go to step 104;

[0035] Step 104, enter the safe operation mode.

[0036] In the operation control method provided by this embodiment, when any monitoring data in the plurality of monitoring data collected by the plurality of sensors is abnormal, it is considered that the system is in an unstable state and has a certain fault. At this time, it is further judged whether the cold storage device is in a normal state, a...

Embodiment 2

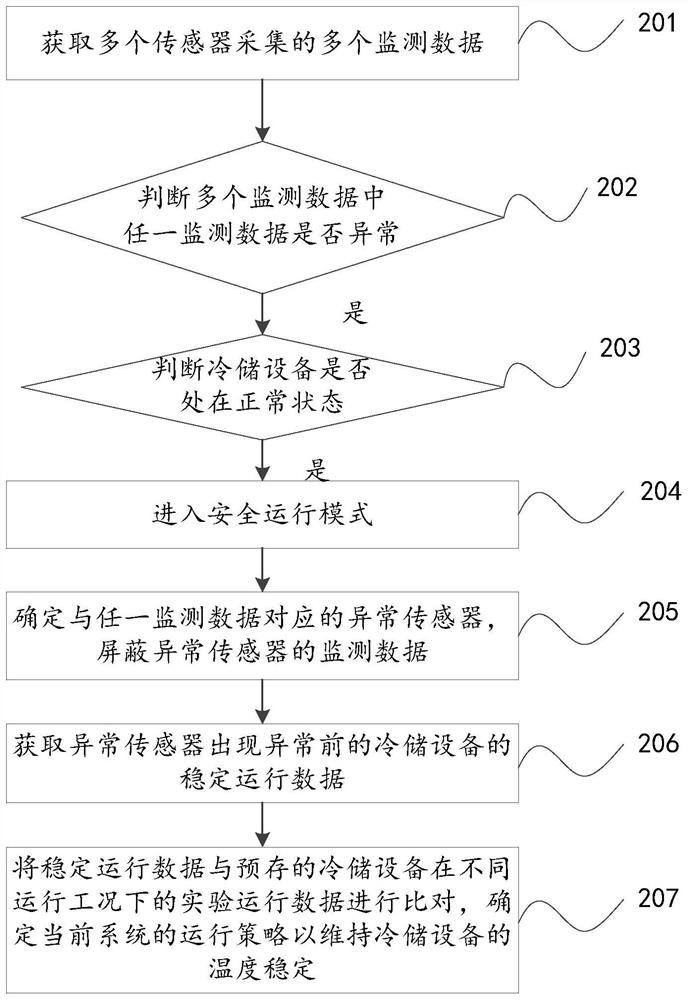

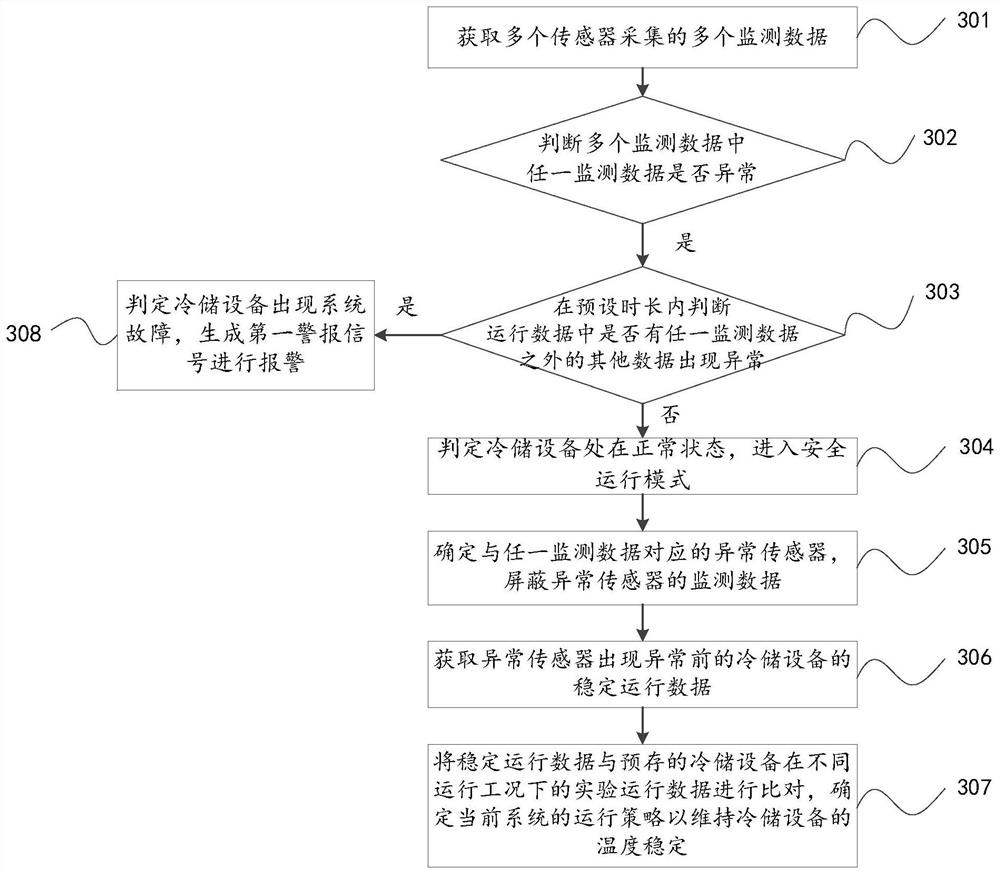

[0038] figure 2 The second schematic flowchart of the operation control method according to the embodiment of the present invention is shown. like figure 2 As shown, the operation control method includes:

[0039] Step 201, acquiring multiple monitoring data collected by multiple sensors;

[0040] Step 202, determine whether any monitoring data in the plurality of monitoring data is abnormal; when it is determined that any monitoring data is abnormal, perform step 203;

[0041] Step 203, determine whether the cold storage device is in a normal state; if so, go to step 204;

[0042] Step 204, enter the safe operation mode;

[0043] Step 205, determine the abnormal sensor corresponding to any monitoring data, and shield the monitoring data of the abnormal sensor;

[0044]Step 206, obtaining stable operation data of the cold storage equipment before the abnormality sensor occurs;

[0045] Step 207 , compare the stable operation data with the pre-stored experimental operat...

Embodiment 3

[0048] In the second embodiment, further, the operation strategy includes the compressor operation frequency and / or the on-off time ratio.

[0049] In this embodiment, it can be understood that the operation strategy includes, but is not limited to, the compressor operation frequency and / or the on-off time ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com