Pressing pump structure with waterproof ring

A waterproof structure and waterproof ring technology, which is applied to individual handheld devices, bottle/can parts, packaging, etc., can solve the problems of contaminated liquid, deterioration, and affecting the use effect, so as to improve the sealing performance and reduce the risk of deterioration , Guarantee the effect of the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings.

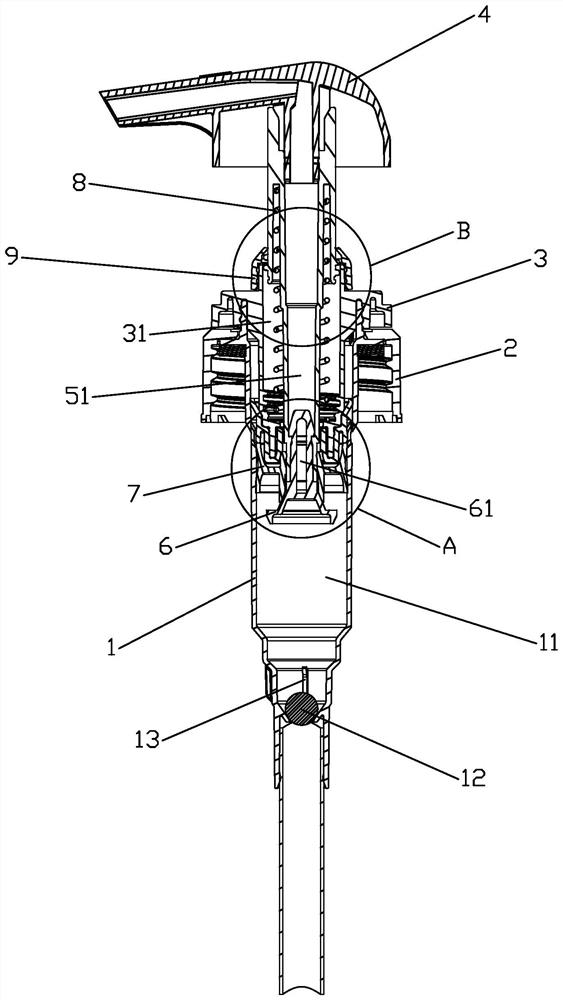

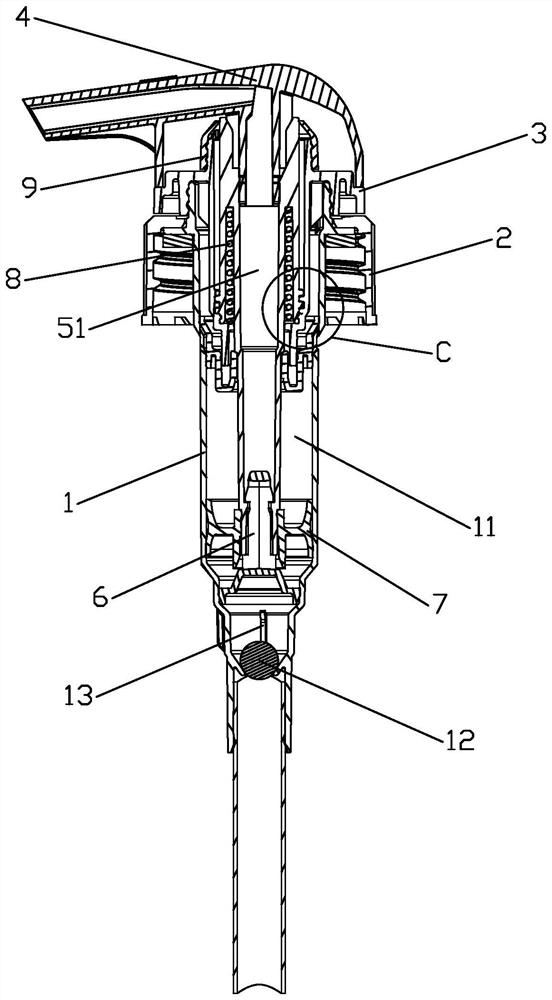

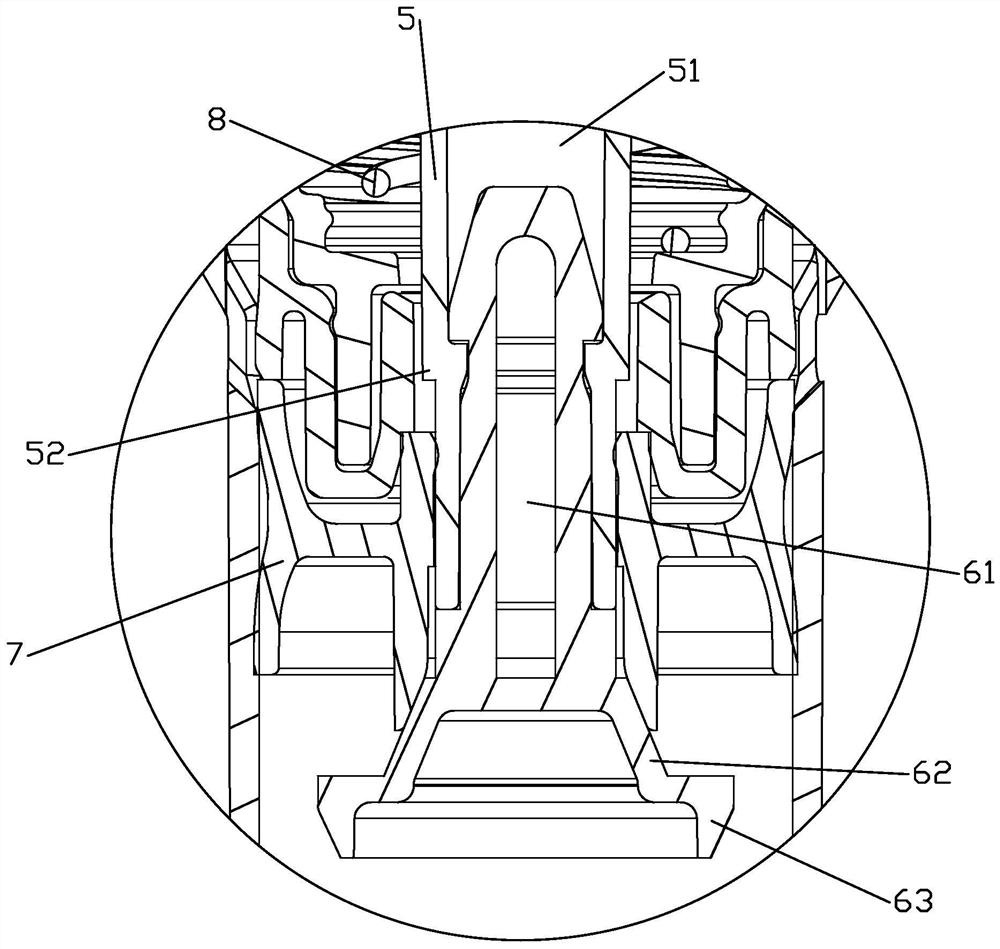

[0022] refer to Figure 1 to Figure 3 , the present invention proposes a pressing pump structure with a waterproof ring, including a pump body 1 extending into the bottle body, a bottle lock cap 2, a lock cap 3, a pressing head 4, a pump chamber 11, an upper pump rod 5, a lower The pump rod 6, the piston 7, the spring 8 and the one-way valve 12, the bottle lock cap 2 is connected to the pump body 1, the lock cap 3 is sleeved on the upper end of the pump body 1, and the pump chamber 11 is arranged on the pump body 1; the upper pump rod 5 is arranged in the pump chamber 11 and has a suction channel 51, the upper end of the upper pump rod 5 is inserted and fixed with the pressing head 4, the lower end of the upper pump rod 5 is connected with the lower pump rod 6, and the lower pump rod 6 is provided with The liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com