Gas flowmeter complete machine automatic leakage detection device and working method thereof

A gas flow meter, working method technology, applied in liquid/vacuum measurement for liquid tightness, by detecting the appearance of fluid at the leak point, etc., it can solve the problem that foam water is easy to splash, flow to the ground, and affect the work site. environment and other problems, to achieve the effect of optimizing sensitivity, simple structure, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

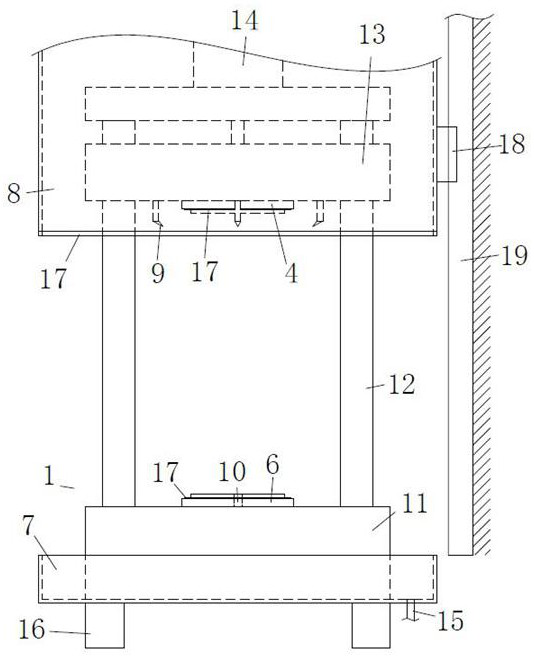

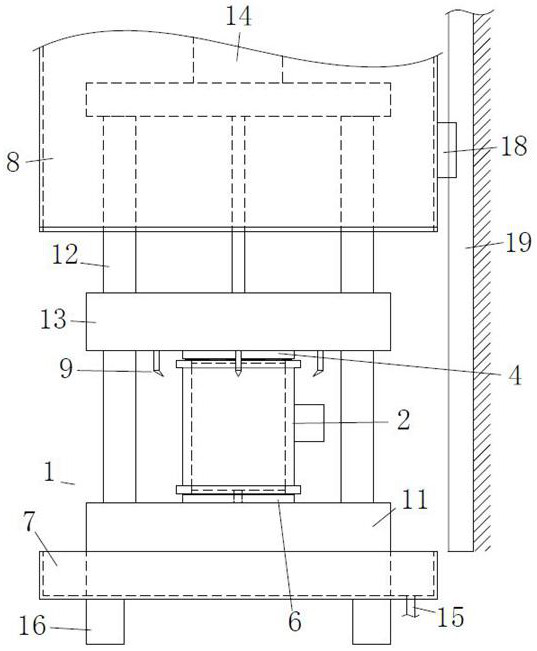

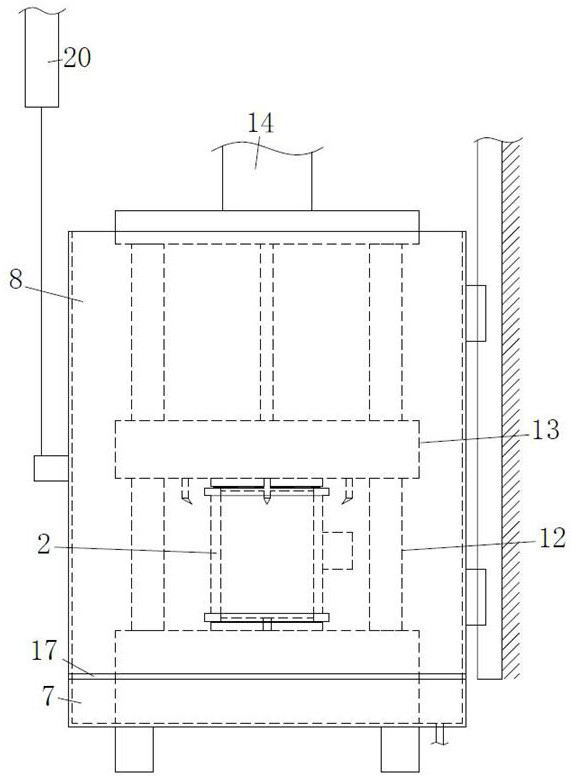

[0042] As shown in the figure, the working method of the automatic leak detection device of the gas flow meter, the working method includes the following steps;

[0043] Step S1, placing the gas flowmeter to be measured in a cylindrical light-absorbing cover, leaving an optical path gap between the outer wall of the gas flowmeter and the light-absorbing cover, and coating the surface of the gas flowmeter with foam water;

[0044] In step S2, a light output end is arranged on the side of one end of the gas flow meter, and a light receiving end is arranged on the side of the other end, and low-brightness detection light is input from the light output end, and the detection light is close to the outer wall of the light-absorbing cover and parallel to the outer wall of the light-absorbing cover. A ring-shaped cylindrical detection light path is formed; the light receiving end uses a light focusing device to focus the detection light at the detection point to form a light spot; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com