Experimental system for representing interlayer interference degree of reservoir

An interlayer interference, experimental system technology, applied in permeability/surface area analysis, suspension and porous material analysis, measurement devices, etc. Achieve the effect of ensuring accuracy and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

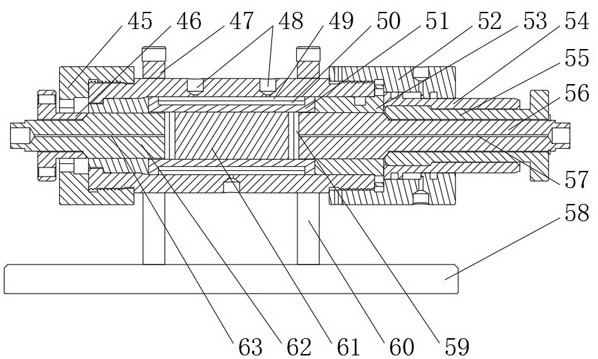

[0035] like Figure 1 to Figure 5 As shown, this embodiment includes a constant pressure and constant speed pump 1, a first six-way valve 2, a simulated formation water storage tank 5, a simulated formation oil storage tank 6 and a second six-way valve 9, and also includes a ring pressure pump 44, a parallel connection The first six-way valve 2 is connected with the simulated formation water storage tank 5 and the simulated formation oil storage tank 6 respectively, and receives the pressure of the constant pressure and constant speed pump 1 and provides simulated formation pressure; The input ends of the two-six-way valve 9 are respectively connected to the simulated formation water storage tank 5 and the simulated formation oil storage tank 6, and the output ends of the second six-way valve 9 are respectively connected to multiple sets of grippers in one-to-one correspondence; The device includes two clamping pipe bodies connected in series, and an air outlet is provided on ...

Embodiment 2

[0044] like figure 2 and Figure 4 As shown, on the basis of Embodiment 1, this embodiment defines a blocking mechanism for closing both ends of the holder, including a left plug 62 and a right plug 56. In the middle of the left plug 62, the right plug The middle part of the head 56 is respectively provided with a liquid inlet hole 63 and a liquid outlet hole 57 which are communicated with the inside of the clamping pipe body; among the two clamping pipe bodies belonging to the same group, the liquid inlet hole 63 of one clamping pipe body is connected to the second and sixth clamping pipe bodies. The output end of the through valve 9 is connected, the liquid outlet hole 57 of the clamping pipe body is communicated with the liquid inlet hole 63 of the other clamping pipe body, and the liquid outlet hole 57 of the other clamping pipe body is provided with a back pressure valve ; On the outer wall of the outer end of the left plug 62, there is a matching shaft sleeve 46, the s...

Embodiment 3

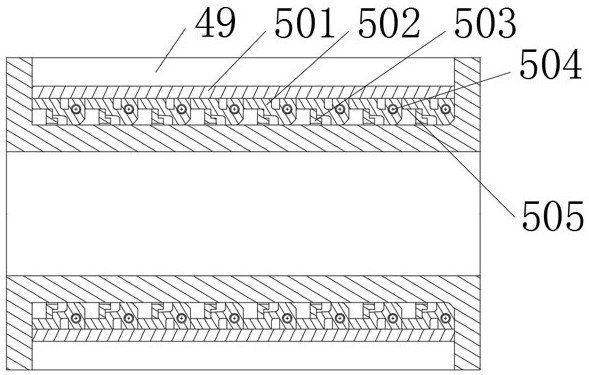

[0050] like figure 2 and image 3 As shown, on the basis of Embodiment 1 and Embodiment 2, this embodiment serves as a fine-tuning mechanism 50 for improving the accuracy of simulated experimental data, including a plurality of arc-shaped plates 501 uniformly arranged along the circumference of the rubber cylinder 51, and The inner walls of the plurality of arc-shaped plates 501 are connected by an adjustment ring, and both end faces of the arc-shaped plates 501 are in contact with the flange side walls. The adjustment ring includes a plurality of rubber sealing rings 502 whose end faces are connected to each other. The part of the ring is in contact with the outer wall of the rubber cylinder 51, and a limit ring 503 is provided on the non-contact parts of the plurality of sealing rings 502. The limit ring 503 is sleeved on the outer circumferential wall of the rubber cylinder 51, and the inner wall of the limit ring 503 A gap 505 is left between the outer circumferential wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com