Container-packaged beverage and method for producing same

A manufacturing method and container technology, applied in the field of container packaging beverages, can solve the problems of disappearance and high volatility of aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1~7

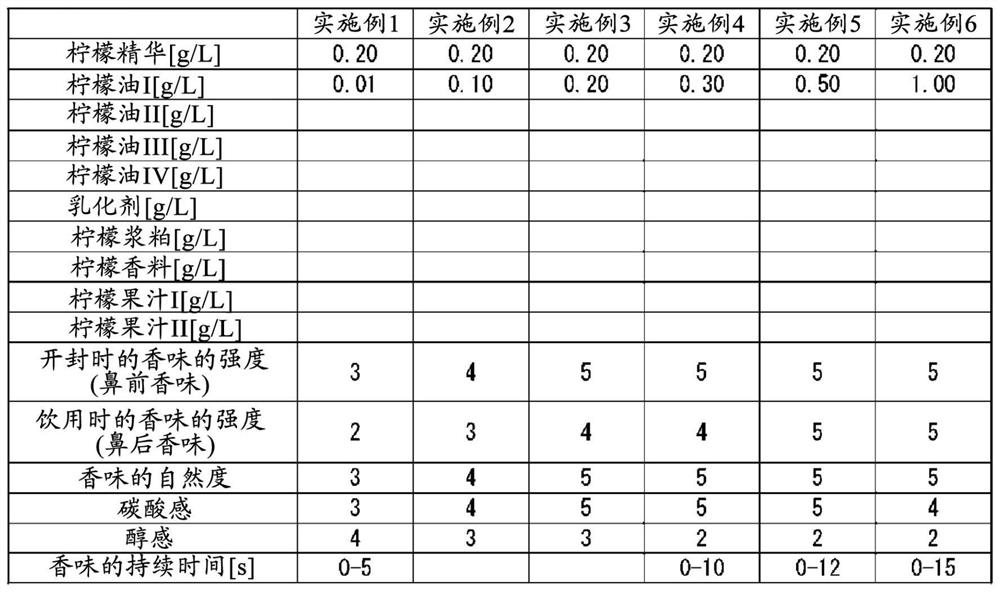

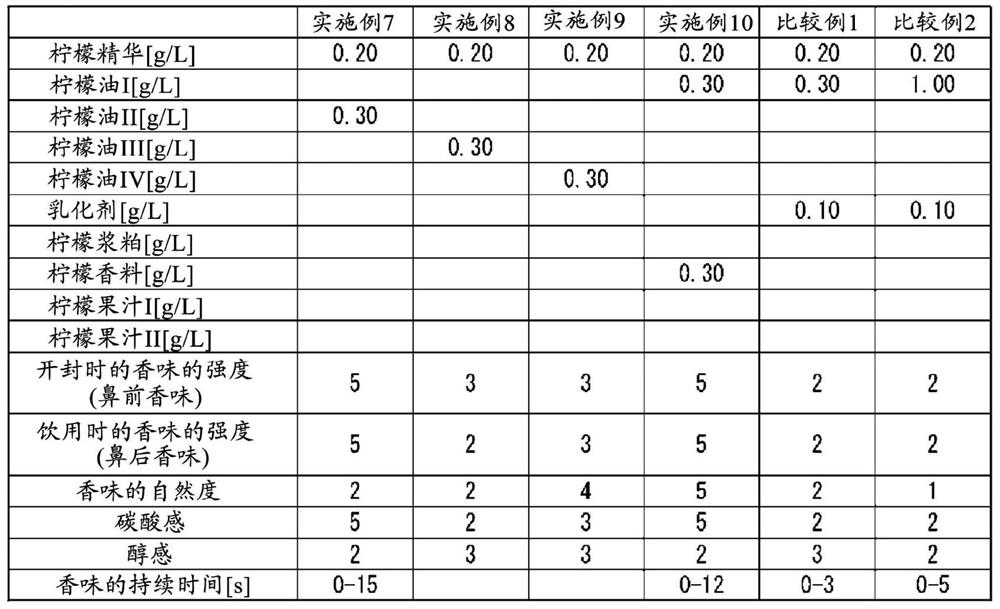

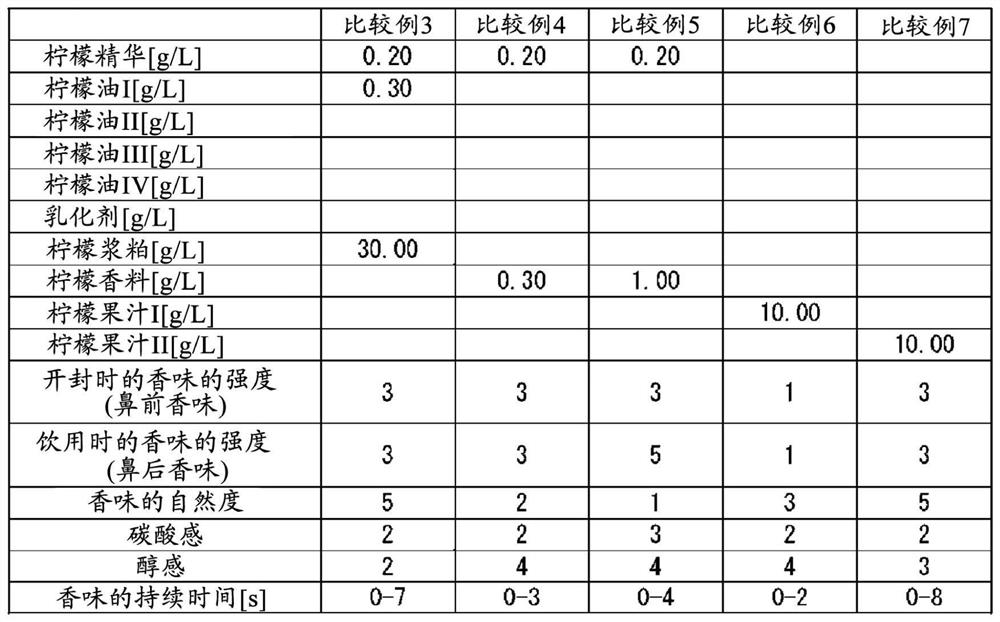

[0148] Container-packed beverages in which a hydrophobic aroma component extracted from the peel of a lemon was contained in a sparkling alcoholic beverage was produced using various methods, and the influence of the hydrophobic aroma component on the flavor of the beverage was investigated.

[0149] First, alcohol (ethanol concentration: 95.3 volume %) 6.1 mass %, sucrose 2.1 mass %, anhydrous citric acid 0.3 mass %, sodium citrate 0.2 mass %, water, and lemon extract (ethanol concentration: 38.0 volume %) were prepared ), emulsifier (lecithin), lemon pulp, lemon flavor (ethanol concentration: 51.4 volume %), lemon juice I, and lemon juice II were mixed so that the amounts described in Tables 1 to 3 were used to prepare matrix liquid. In the prepared base liquid, lemon oil I, lemon oil II, lemon oil III, and lemon oil IV were further mixed to the amounts described in Tables 1 to 3 to obtain Examples 1 to 10 and Comparative Examples 1 to 7. each drink.

[0150] In addition, ...

Embodiment 11~16

[0172] Citrus oils other than lemon were added in a liquid-separated state from the base liquid of the beverage, and the influence on the flavor was investigated.

[0173] The citrus oil used is a hydrophobic composition (mono oil) extracted from the peel of citrus, and a hydrophobic composition obtained by removing a part of the terpene olefin of the mono oil to increase the content ratio of the terpenoid. A hydrophobic liquid composition obtained by mixing a hydrophobic composition (folding oil).

[0174] In the same manner as in Example 1, except that various oils were used in place of the lemon oil I, a container-packaged beverage was produced, and sensory evaluation was performed. In all beverages, oil droplets were observed on the beverage surface. The results are shown in Table 4.

[0175] [Table 4]

[0176]

[0177] According to this result, in all the beverages, as in Example 4, both the pre-nasal flavor and the post-nasal flavor were enhanced. In addition, the...

manufacture example 1

[0180] First, in the same manner as in Example 4, 700 mL of matrix liquid was prepared. Next, 350 mL of the base liquid was respectively filled into the can bodies of two aluminum (alloy) two-piece beverage cans. Next, the same amount of lemon oil I was added dropwise to the liquid surface, respectively, to prepare a beverage in which the lemon oil and the base liquid were separated and floated. Then, a sealed two-piece beverage is produced by rolling a can lid (stay-on tab lid) coated with a sealing compound containing styrene-butadiene rubber as a main component to the can body Cans for packaging beverages.

[0181] In addition, the inner diameter of the can body of the aluminum (alloy) two-piece beverage can used was 65.9 mm (the area of the liquid surface of the base liquid: 3.4×10 -3 m 2 ), the inner diameter of the opening is 54.9 mm (the area of the opening: 2.4×10 -3 m 2 ), when lemon oil I was added dropwise, it rebounded at the liquid level, and although it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com