Electric machine

A machine and electric technology, applied in electric components, electromechanical devices, electrical components, etc., can solve problems such as reduced motor efficiency, high machine loss, and oil entering the air gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

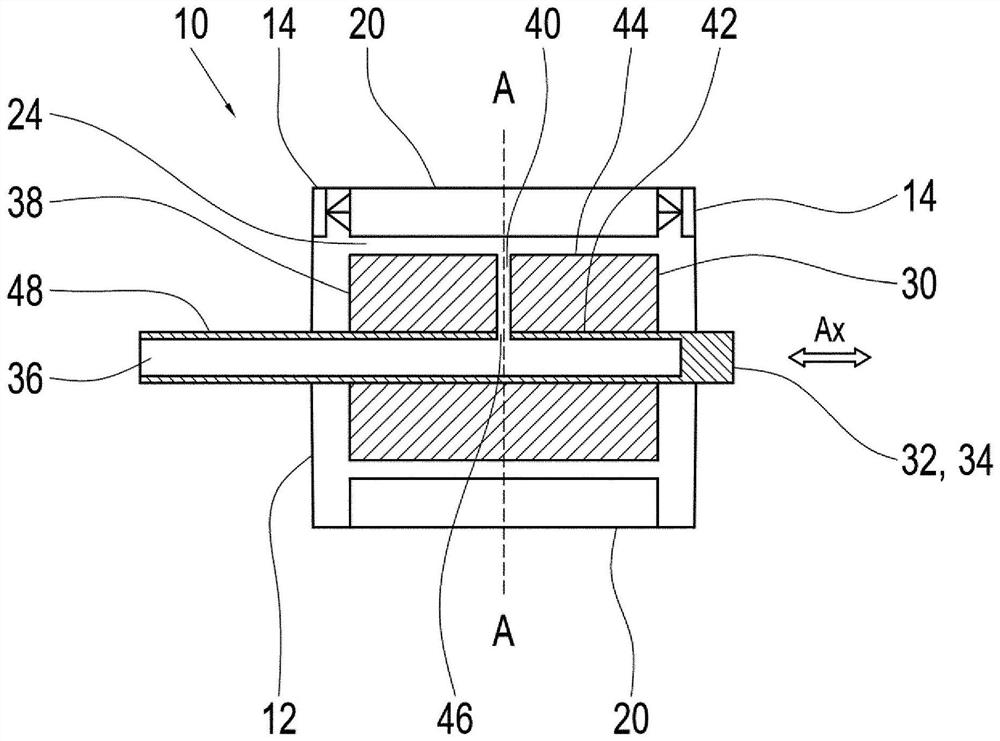

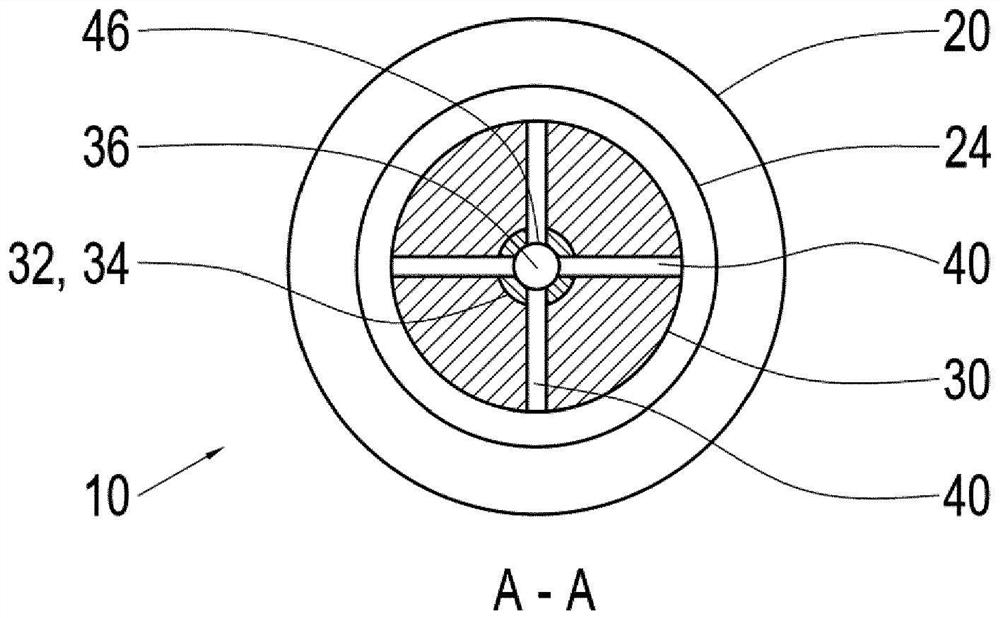

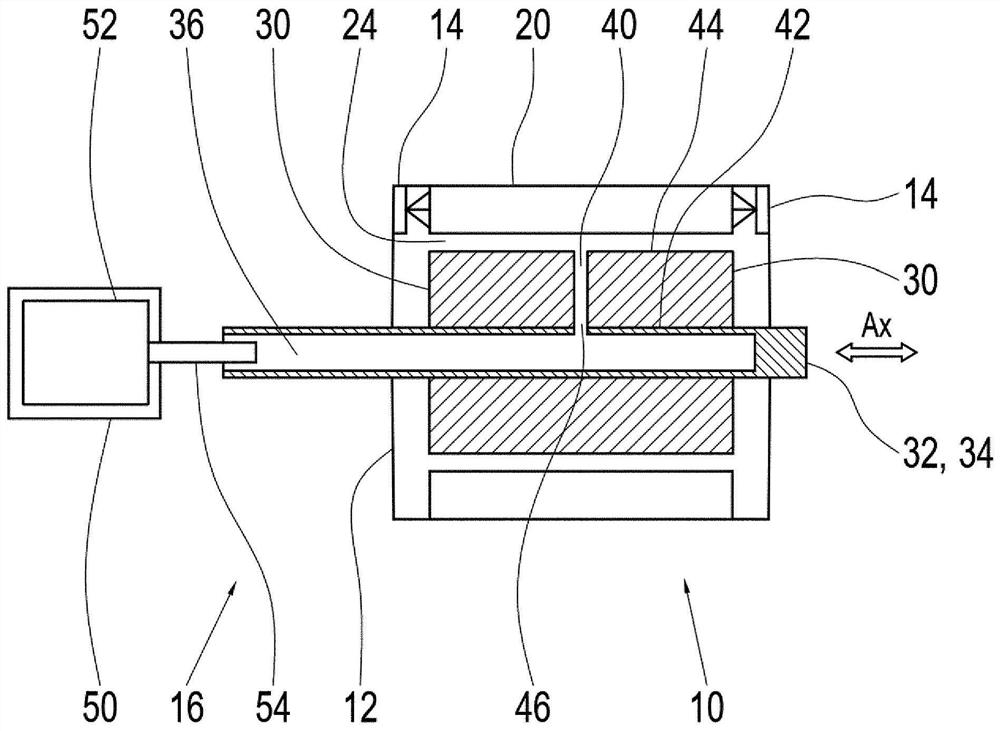

[0032] figure 1 An electric machine 10 according to the invention is shown, which has a housing 12 and a rotor 30 with a rotor shaft 32 in which a stator 20 is arranged in a stationary manner. The electric machine 10 of cylindrical design is arranged such that the rotor 30 rotates within the stator 20 .

[0033] The housing 12 also includes a cooling device 14 which sprays a coolant, preferably an oil-based coolant, onto the axial side of the stator 20 in order to cool the stator 20 . The winding heads sprayed by the cooling device 14 arranged at the axial ends are not shown in the schematic sectional view of the electric machine 10 .

[0034] The stator 20 and the rotor 30 are arranged such that an air gap 24 is formed therebetween. By spraying the stator 20 with a cooling liquid, such as oil, it is possible for the cooling liquid to penetrate into the air gap 24 .

[0035] The rotor shaft 32 is designed as a hollow shaft 34 and has an axial bore 36 which extends into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com