Plant polysaccharide extraction equipment and method

A technology for extracting equipment and plant polysaccharides, applied in cleaning methods and utensils, chemical instruments and methods, grain processing, etc., can solve problems affecting product quality, filtration difficulties, and affecting work efficiency, so as to shorten the extraction time and improve collection effect, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

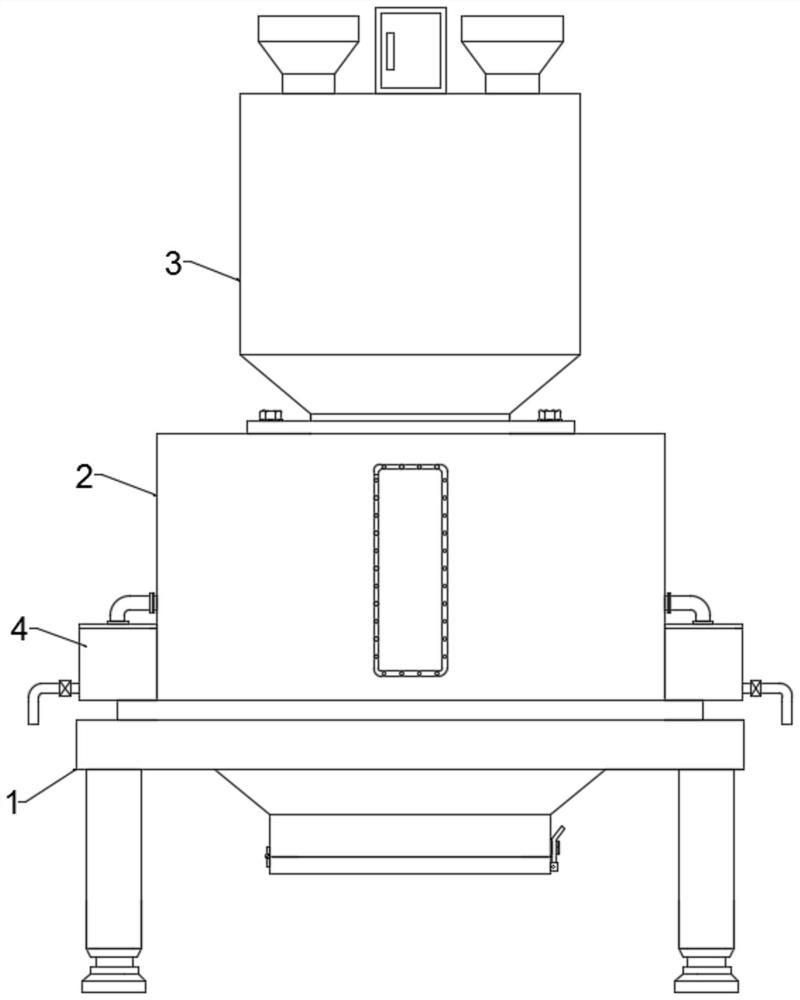

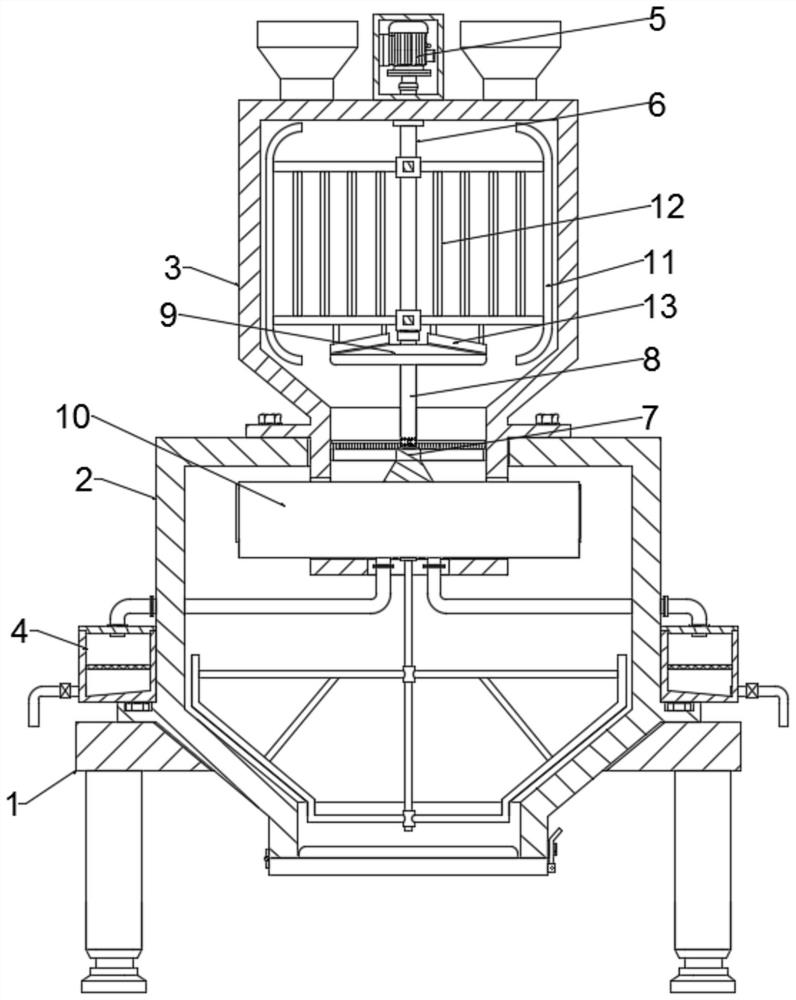

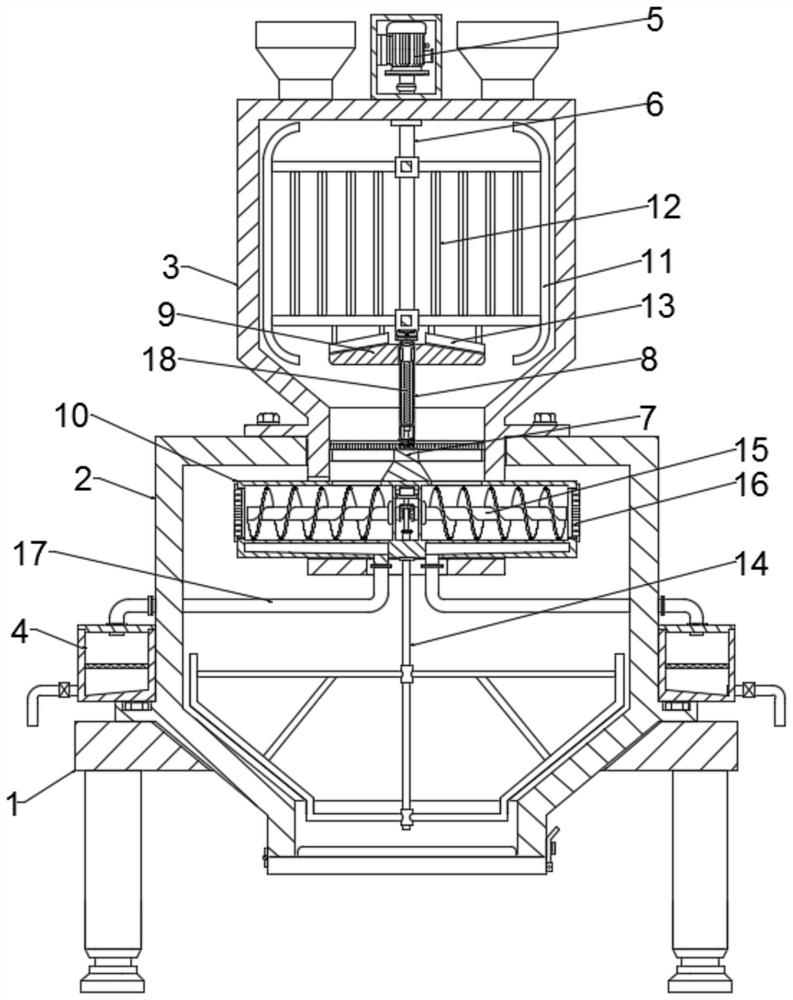

[0024] Example: see Figure 1-6 , plant polysaccharide extraction equipment and method, comprising a mounting seat 1, a preparation box 2 arranged on the top of the mounting seat 1 and a crushing box 3 arranged on the top of the preparation box 2, and both sides of the top of the crushing box 3 are provided with a feeding hopper. , the lower parts of both sides of the preparation box 2 are provided with a liquid collecting box 4, the bottoms of the preparation box 2 and the crushing box 3 are both funnel-shaped boxes, and the bottom end of the crushing box 3 penetrates into the interior of the preparation box 2; The inside of the box 3 is provided with a crushing mechanism for plant crushing; the bottom of the crushing box 3 in the preparation box 2 is transversely provided with a pressing box 10, and the pressing box 10 is provided with a filter pressing mechanism for solid-liquid separation of materials; Inside the preparation box 2, there is a scraping component for materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com