Solid-liquid separation device for petroleum refining

A technology of solid-liquid separation and separation device, which is applied in the direction of centrifuges, centrifugal refining, centrifuges with rotating drums, etc., which can solve the problem of slow filter screen speed, small filter screens, and unclean separation of fine solids and other problems, to achieve the effect of convenient operation and reduction of adhesion residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

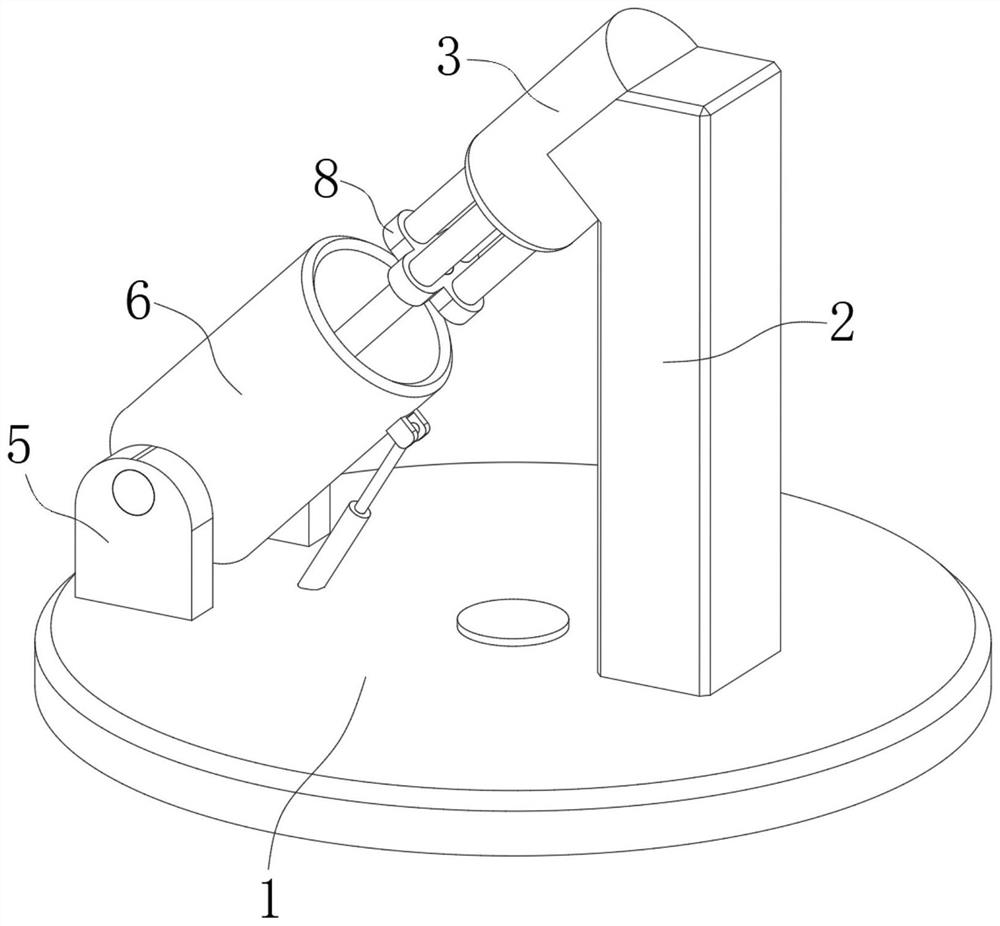

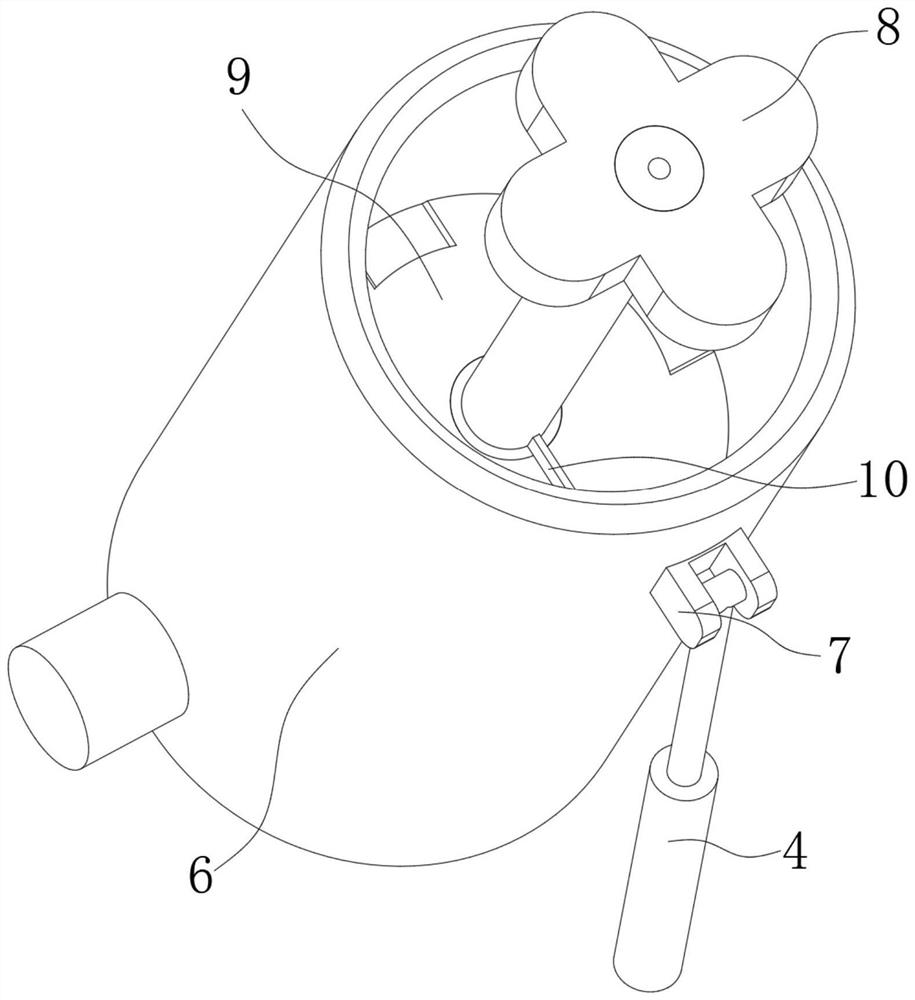

[0029] see Figure 1-Figure 2, a solid-liquid separation device 9 for petroleum refining and chemical use in the figure, including a centrifugal base 1, a separation device 9 and a cleaning device 10, the centrifugal base 1 is fixedly connected with a device frame 2, and the device frame 2 is fixedly connected with a hydraulic pusher Rod 3, an electric telescopic rod 4 is fixedly connected to the centrifugal base 1, an installation frame 5 is fixedly connected to the centrifugal base 1, a cylinder 6 is rotatably connected to the installation frame 5, and the cylinder 6 is fixedly connected to the electric telescopic rod 4. The output end is rotatably connected to the fixed block 7, the output end of the hydraulic push rod 3 is fixedly connected with a connecting block 8, the separation device 9 is installed on the connecting block 8, and is used to extract the oil that has been stratified after centrifugation. The cleaning device 10 is installed in the The separation device 9 ...

Embodiment 2

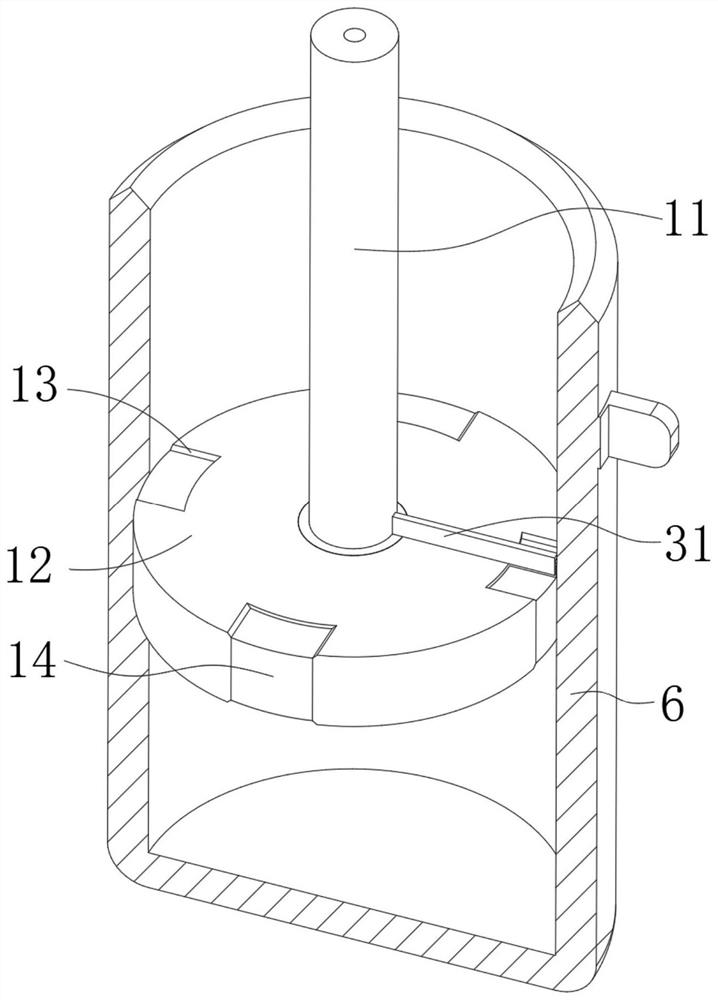

[0034] see Figure 7-Figure 10 The second embodiment will be described. This embodiment will further describe the first embodiment. The linkage 16 in the figure includes a first spring 18 fixedly installed in the separation groove 13. The first spring 18 is fixedly connected with the stopper 14 and pushes the rod. The bottom end of 11 is fixedly connected with a pulling block 19 which is slidably connected with the device slot 15. A guide groove 20 is opened on the push plate 12, and a first pull rope 21 is slidably connected in the guide groove 20. One end of the first pull rope 21 is connected to the stopper. The block 14 is fixedly connected, and the other end is fixedly connected to the pulling block 19 , a fixing rod 22 is fixedly connected in the device slot 15 , and a fixing plate 23 is fixedly connected to the bottom end of the fixing rod 22 .

[0035] see Figure 4-Figure 6 , the balance piece 17 in the figure includes a fixing ring 24, the push rod 11 is provided wi...

Embodiment 3

[0039] see Figure 4-Figure 6 Embodiment 3 will be described. This embodiment will further describe Embodiment 1. The cleaning device 10 in the figure includes a rotating ring 30 that is rotatably connected to the device groove 15. The rotating ring 30 is fixedly connected with a sliding connection with the upper surface of the push plate 12. The cleaning rod 31, the cleaning rod 31 is provided with a cleaning member 32 for cleaning the depressions on the push plate 12, and the device groove 15 is provided with a rotating ring 30 for rotating when the push rod 11 is pulled, and when the push rod 11 is pushed The moment when the disk 12 is separated from the inner wall of the cylinder 6, the driving member 33 for scraping the oil on the upper surface of the disk 12 is pushed.

[0040] see Figure 7-Figure 10 , the driving member 33 in the figure includes a clockwork spring 34 fixedly installed in the device slot 15, one end of the clockwork spring 34 is fixedly connected with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap