Intelligent manufacturing, producing and machining equipment for thrust ball pin

A technology of intelligent manufacturing and processing equipment, applied in metal processing equipment, manufacturing tools, safety equipment and other directions, can solve the problems of automation equipment rhythm difficult to keep consistent, low work efficiency, large work area, etc., to achieve convenient adjustment and improve production efficiency , Improve the effect of production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

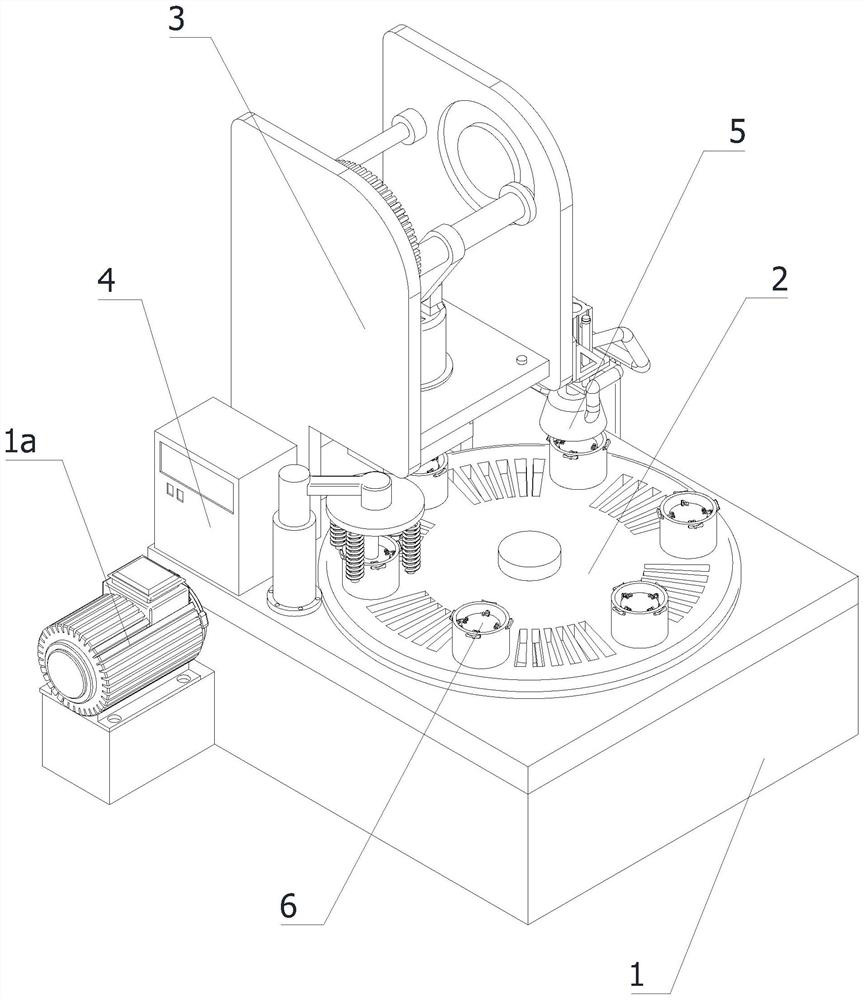

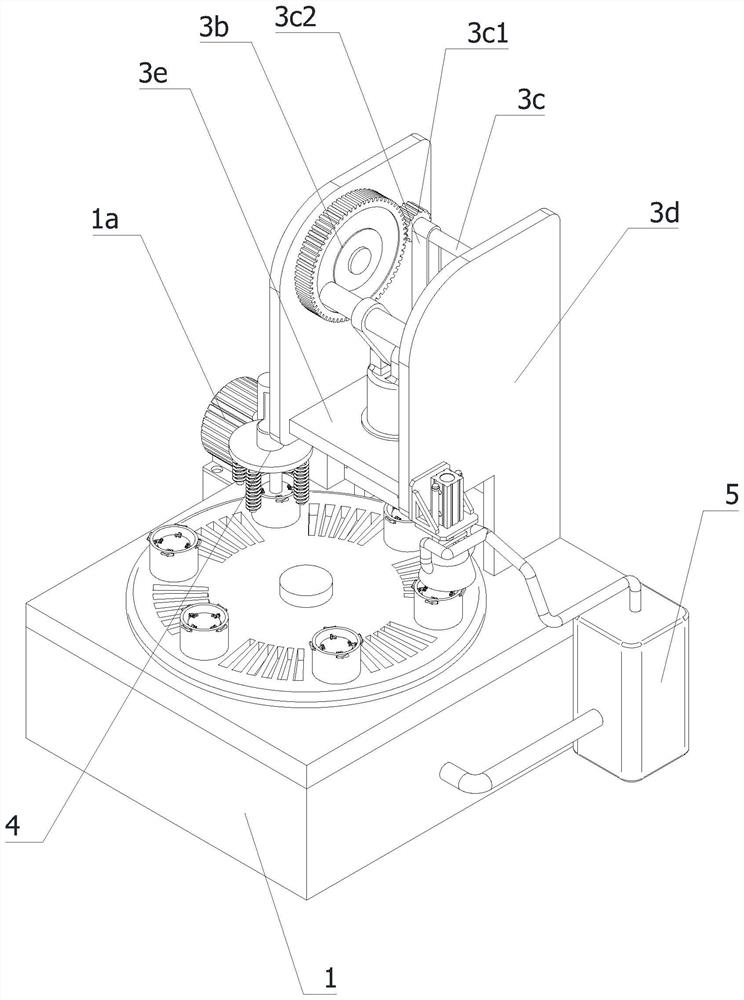

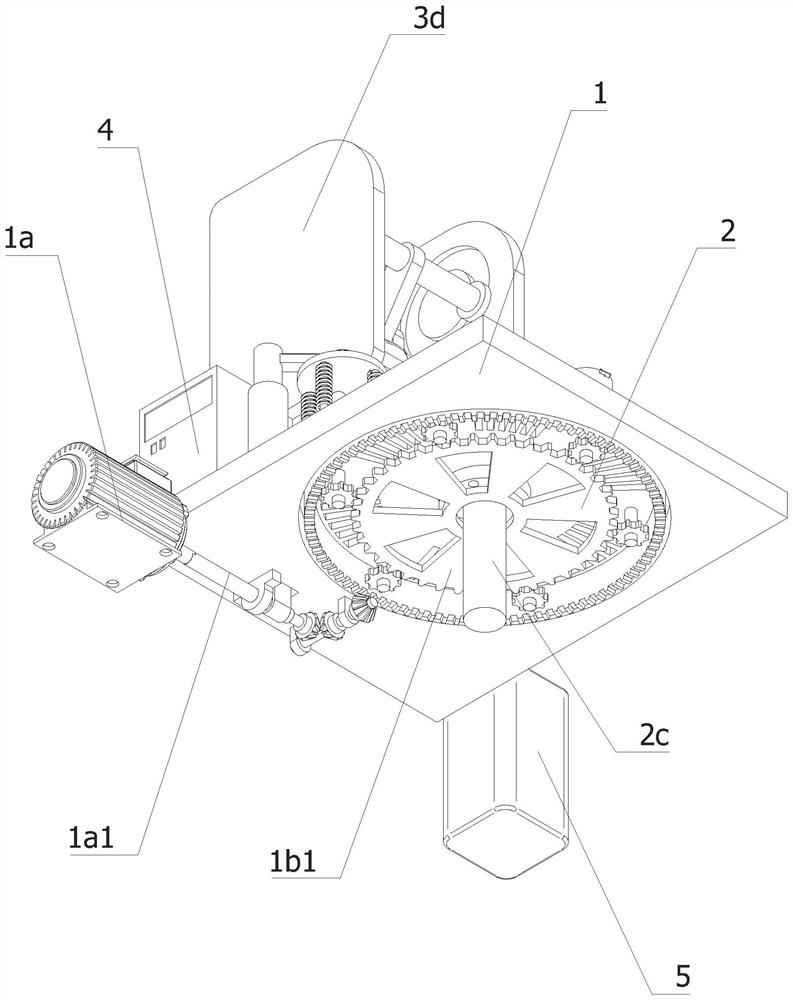

[0047] like figure 1 and figure 2 shown:

[0048] An intelligent manufacturing, production and processing equipment for thrust ball pins, comprising a worktable 1, a drive motor 1a, a main shaft 1a1, a material transfer turntable 2, a stamping assembly 3, a heating assembly 4 and a cooling assembly 5, the worktable 1 is connected to the ground, the main shaft 1a1 It is located in the interior of the workbench 1 in a horizontal state, the drive motor 1a is located on the side of the workbench 1, the output shaft of the drive motor 1a runs through the side wall of the workbench 1 and is fixedly connected with the main shaft Above, the material transfer turntable 2 is connected with the main shaft 1a1 in a driving man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com