Side milling type electrolytic milling electrode and electrolytic milling machining milling head

A milling and side milling technology, applied in the field of electrolytic milling, can solve problems such as electrolyte spillage and loss, and achieve the effects of avoiding design and manufacturing complexity, avoiding loss, and improving electrolyte flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

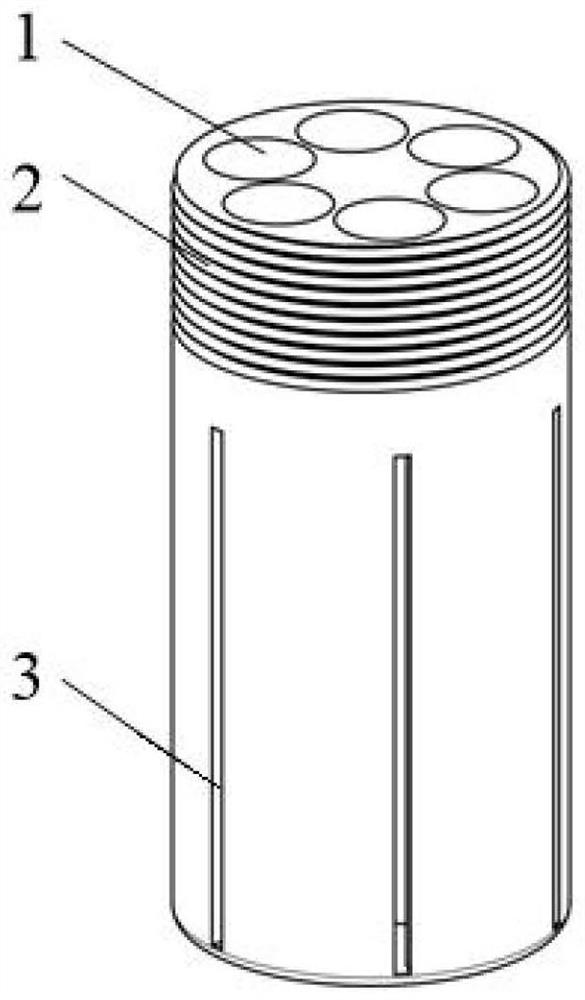

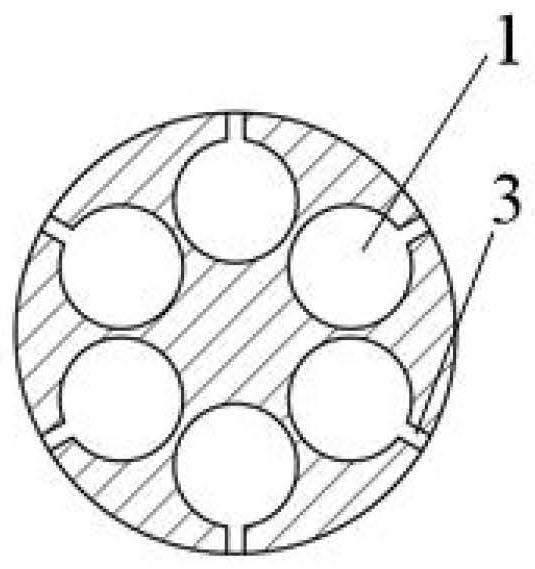

[0054] The machined part is a TC4 test block, and one side wall of the test block is removed by internal jet side milling electrolytic milling. The geometric size of the test block is 30 mm × 30 mm × 100 mm, the electrode size is 20 mm in diameter, and the side wall has 6 narrow slit liquid ejection ports, the slit width is 1 mm and the length is 21 mm.

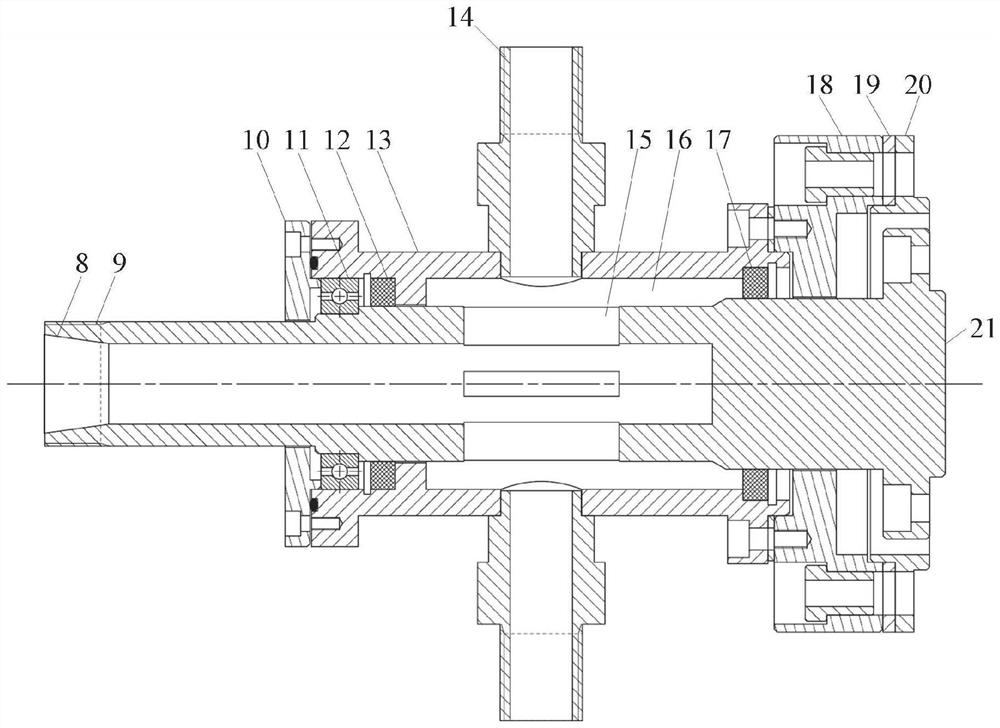

[0055] Install the inner jet milling head and inner cavity electrode according to the technical scheme. After the installation is completed, the parts are connected to the positive pole of the power supply, and the electrode is connected to the negative pole of the power supply. Electrolytic milling process parameters and power supply parameters are selected, a certain machining voltage is applied between the electrodes, the electrolyte is flushed from the machining gap at a high speed with a certain pressure, and the electrodes are fed at the same time until the machining is completed.

[0056] Processing parameters: the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com