Machining clamp for lever part drilling

A technology of parts and levers, which is applied in the field of processing jigs for drilling of lever parts, can solve problems such as inability to use, and achieve the effects of prolonging service life, improving processing efficiency, and simplifying structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

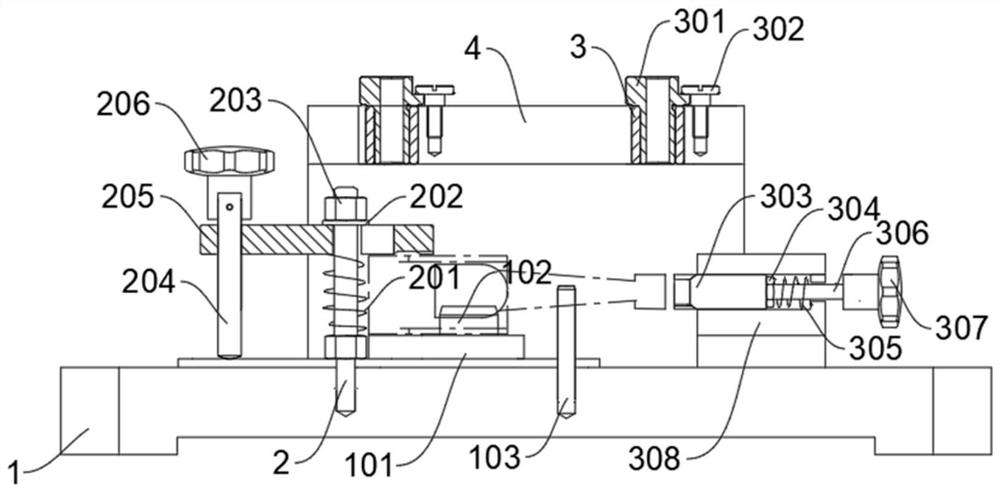

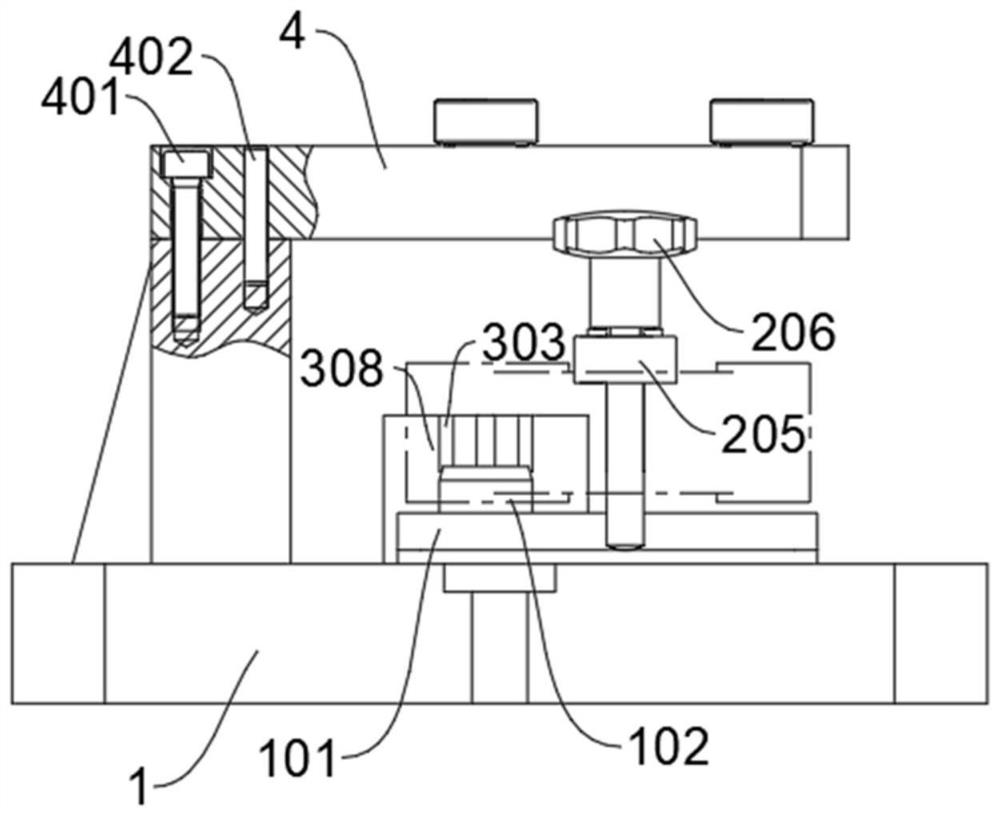

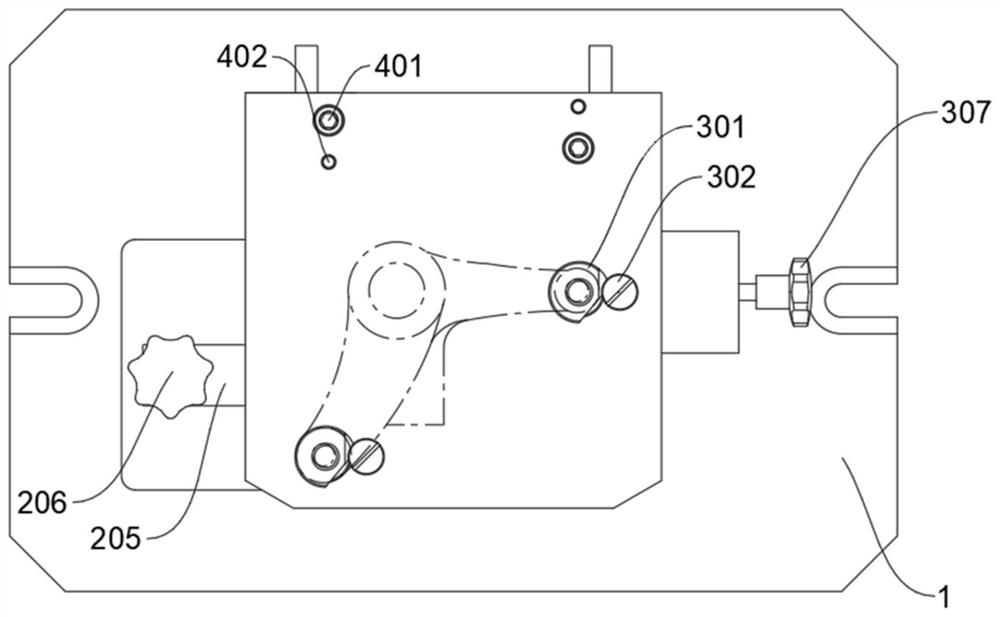

[0031] like Figure 1-4 As shown, a processing fixture for drilling a lever part includes a clamping body 1, a support plate 101 fixedly connected to the boss on the upper surface of the clamping body 1, and a vertical plate fixedly connected to the edge of the upper surface of the clamping body 1, It should be added that the middle section of the upper surface of the clamp body 1 is provided with open ear seats, so that the clamp body 1 can be fixedly connected to the workbench of the drilling machine through the open ear seats, and the upper surface of the support plate 101 is fixedly connected with The positioning pin 102, the anti-reverse pin 103 is fixedly connected to the upper surface of the clamping body 1, the upper end of the vertical plate is fixedly connected to the drilling template 4 through the inner hexagon socket head screw 401 and the cylindrical pin 402, and the drilling template 4 is connected with the drilling mechanism, the clamp The upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com