Steel structure tool for adjusting posture of through opening

A steel structure and tooling technology, applied in workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of uncontrollable precision and complicated assembly process, and achieve the effect of convenient parameter adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, content and advantages of the present invention clearer, the specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

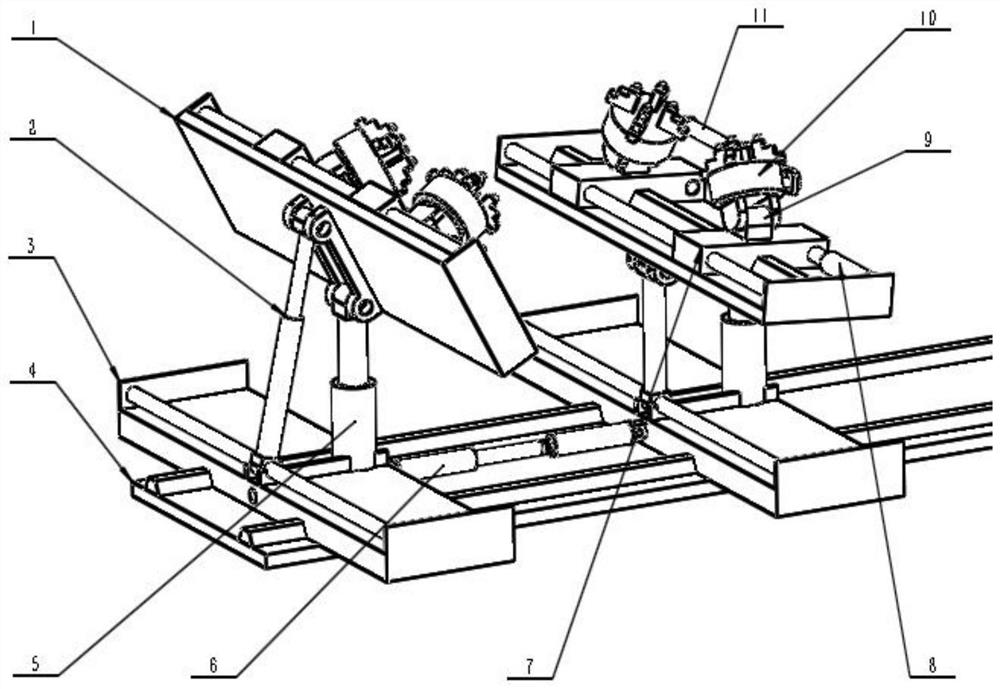

[0014] This embodiment proposes a steel structure tooling for adjusting the attitude of the opening, the structure of which is as follows figure 1 As shown, it includes pitch bracket 1, pitch cylinder 2, base 3, slide rail 4, lift cylinder 5, longitudinal adjustment cylinder 6, sliding module 7, lateral adjustment cylinder 8, universal joint 9, chuck 10 and included angle Adjust the cylinder 11.

[0015] Two sets of bases 3 are arranged on the slide rail 4 , and a longitudinal adjustment oil cylinder 6 is arranged between the two sets of bases 3 . Each group of bases 3 is provided with a lifting cylinder 5 and a pitching cylinder 2, the cylinder body of the lifting cylinder 5 is fixedly connected to the bottom of the base 3, the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com