Novel injection molding machine

An injection molding machine and a new type of technology, applied in the field of injection molding machines, can solve the problems of melting plastic particles, blockage of hoppers, and poor cooling effect of cooling water, and achieve the effects of accelerating heat dissipation and cooling, good recycling, and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the accompanying drawings. Wherein the same parts are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "top", "bottom", "bottom" and "top" used in the following description refer to the Orientation, the words "inner" and "outer" refer to directions toward or away from the geometric center of a particular component, respectively.

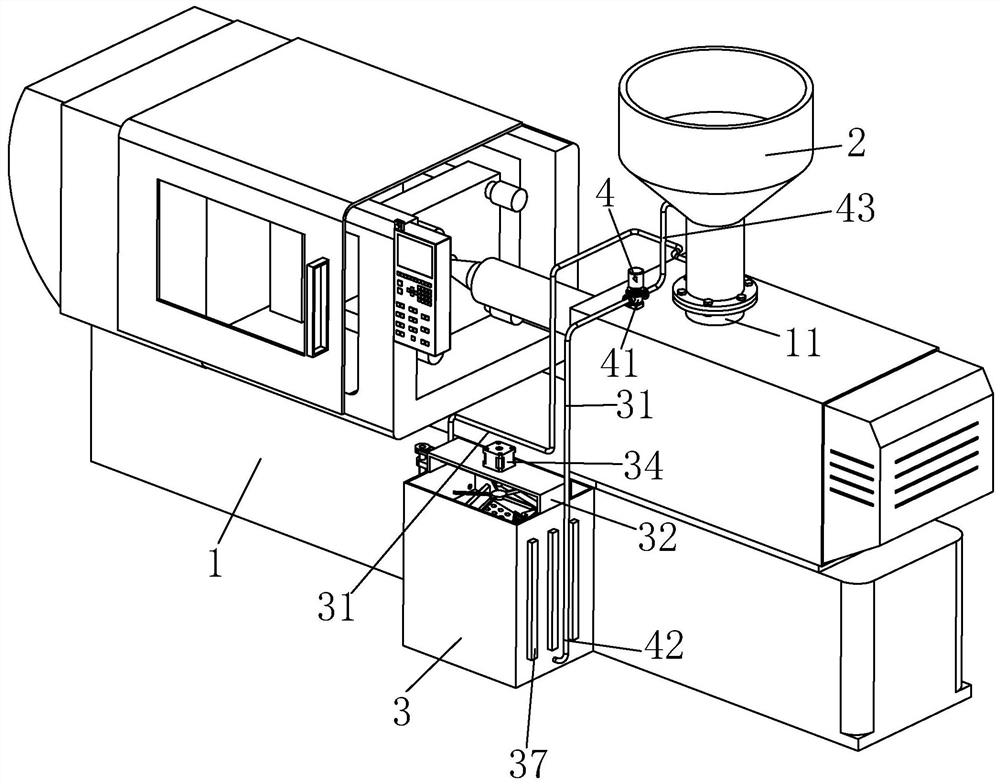

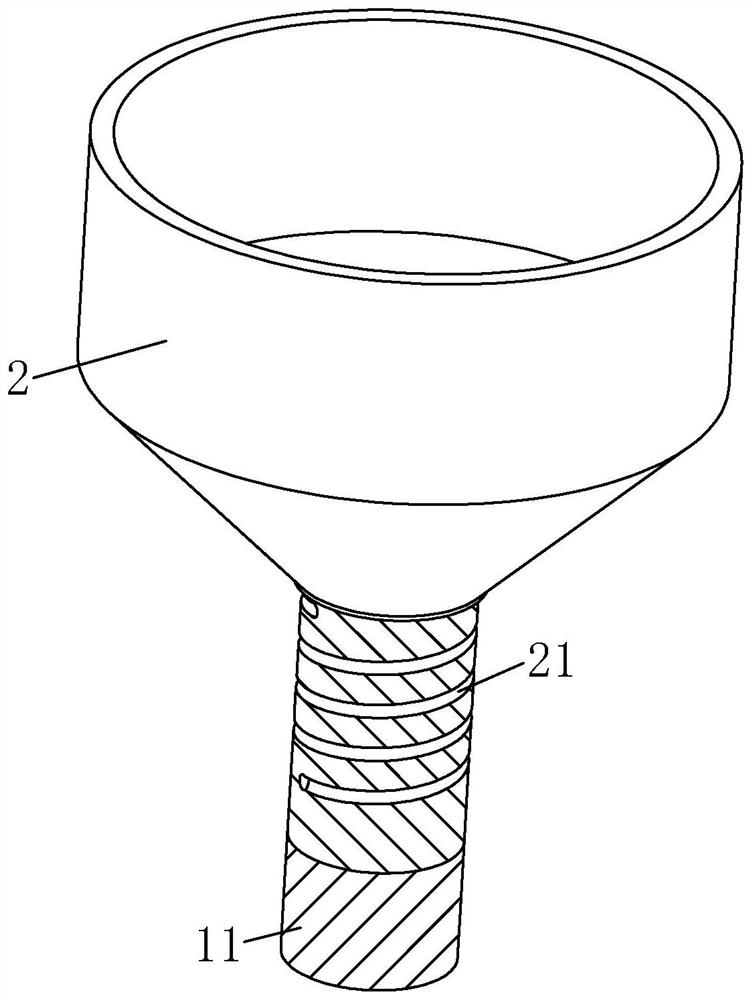

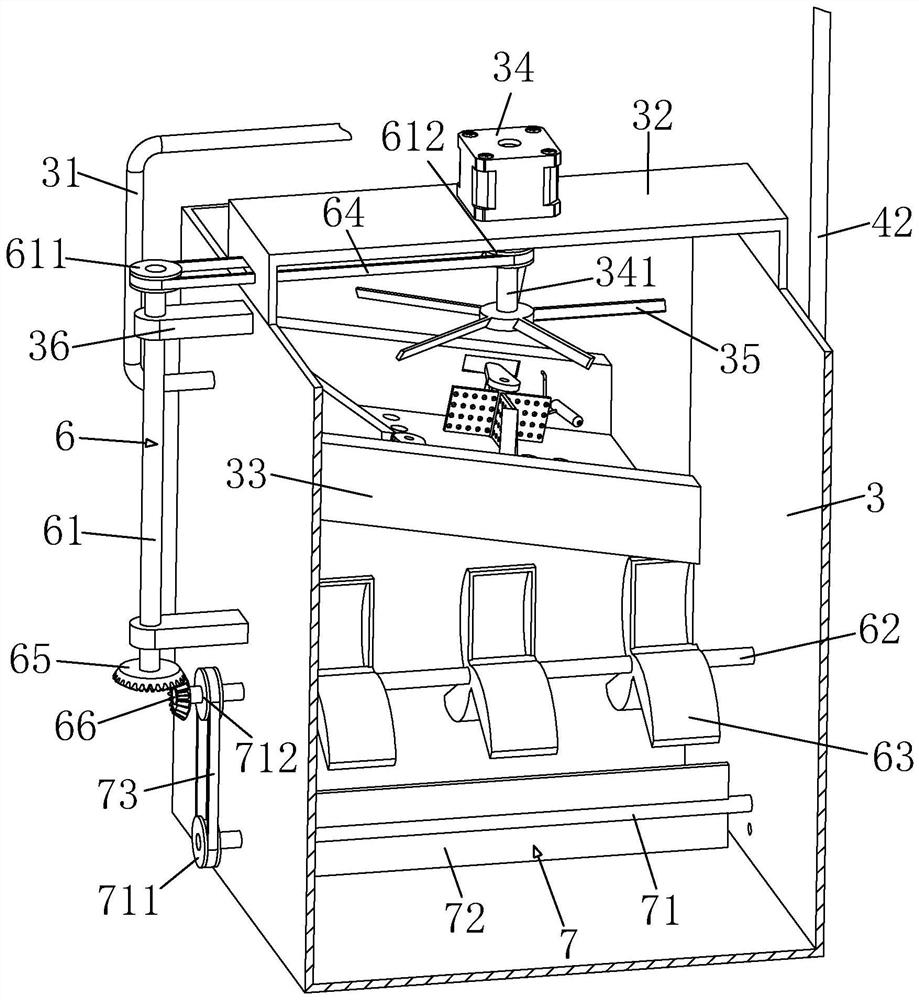

[0037] The invention discloses a novel injection molding machine, such as figure 1 and figure 2 As shown, it includes an injection molding machine body 1; a hopper 2 is detachably installed on the top of the injection molding machine body 1, and a water tank 3 is fixed on the side wall of the injection molding machine body 1; There is a cooling channel 21 inside the wall; the cooling channel 21 is spiral; the injection molding machine body 1 is provided with a conveying mechanism 4 for conveying cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com