Lifting mechanism for hanging and conveying pouring barrel

A hanging and No. 1 technology, applied in the field of hanging conveyor lines, can solve problems such as pouring barrel shaking, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

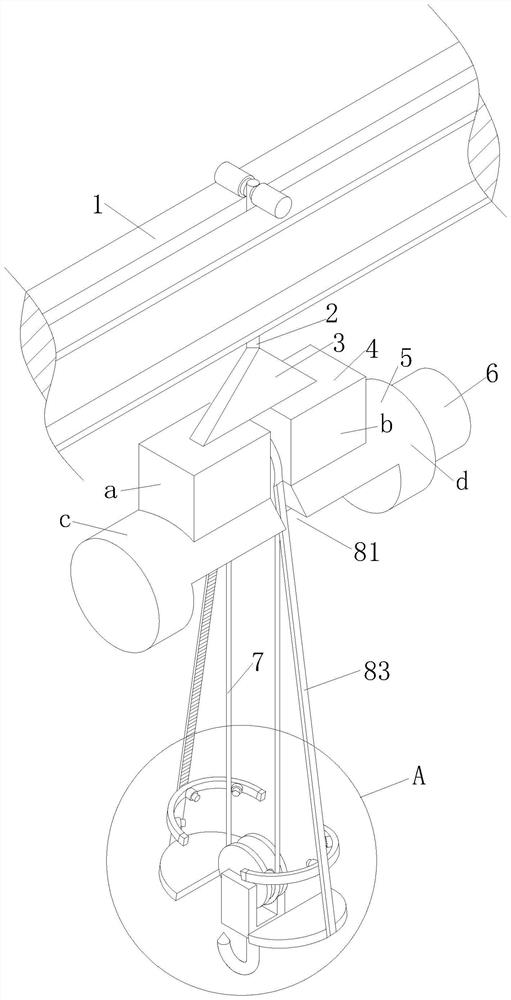

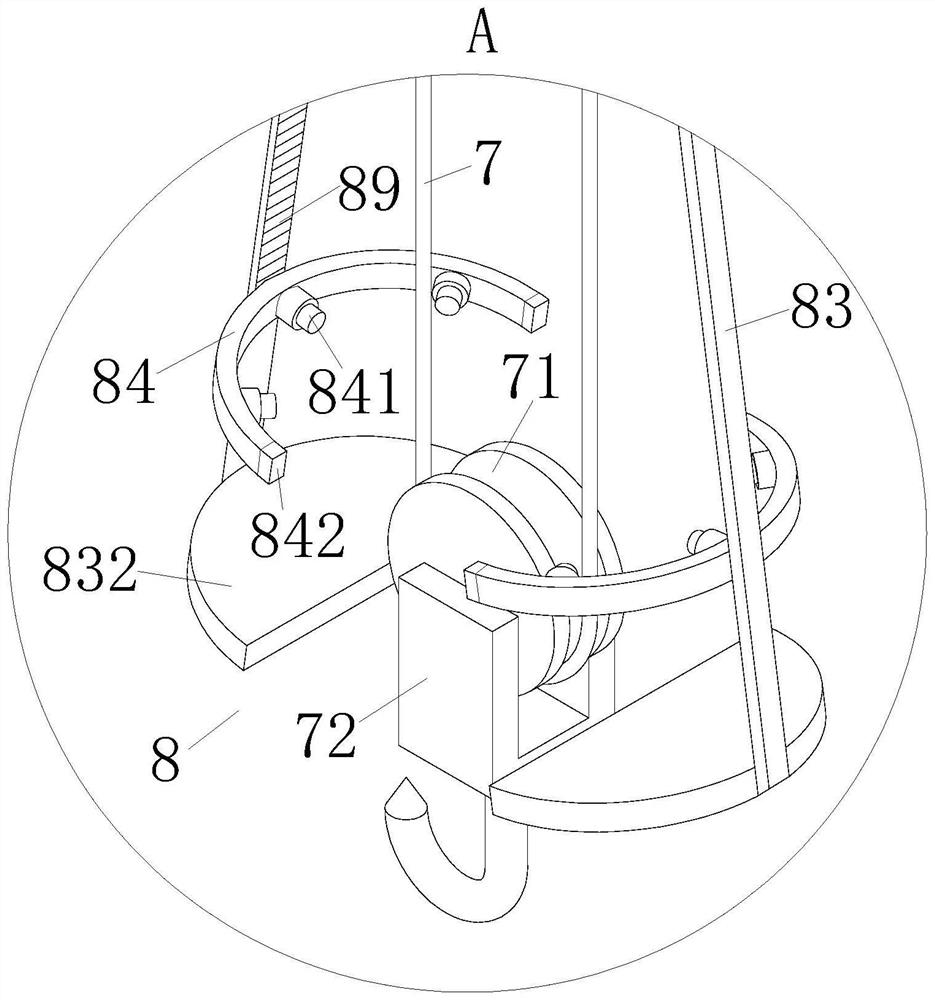

[0050] As a specific embodiment of the present invention, the stabilization mechanism 8 includes:

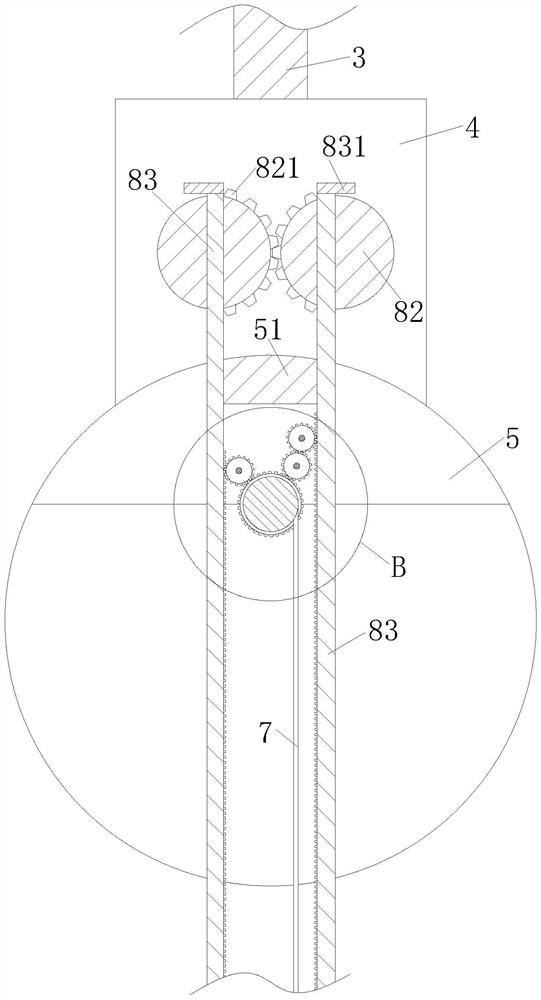

[0051] A turntable 82, the turntable 82 is located in the cavity 81 and is rotatably connected to the side wall of the control box 4, and the turntable 82 is two;

[0052] Clamping rods 83, the clamping rods 83 are two and both pass through the turntable 82 and are slidably connected to the turntable 82;

[0053] There are two clamping frames 84 , and both of the clamping frames 84 are fixedly connected to the position of the clamping rod 83 near the bottom.

[0054] As a specific embodiment of the present invention, the turntable 82 is provided with latching teeth 821 on the side wall of the control box 4 that is close to and adjacent to the turntable 82, and the latching teeth 821 are engaged with each other; the control A drive motor is fixed inside the box 4 , and one of the turntables 82 is fixedly connected to the output shaft of the drive motor.

[0055] During operatio...

Embodiment approach

[0057] As a specific embodiment of the present invention, the No. 2 gear 86 , the No. 3 gear 87 and the No. 4 gear 88 have the same specifications and sizes, and the diameter of the index circle of the No. 1 gear 85 is the same as that of the No. 2 gear 86 , the No. The diameter of the index circle of the gear 87 and the fourth gear 88 is four times, and the number of teeth of the first gear 85 is twice that of the second gear 86 , the third gear 87 and the fourth gear 88 .

[0058] During operation, when the turntable 82 drives the clamping rod 83 and the clamping frame 84 to clamp the pouring bucket, the clamping rod 83 is just in a vertical state, and the racks 89 on the two clamping rods 83 are respectively It meshes with the No. 2 gear 86 and the No. 4 gear 88. When the winding shaft 61 rotates counterclockwise to lift the pouring barrel, the No. 1 gear 85 coaxial with the winding shaft 61 rotates, and the No. 1 gear 85 drives the No. 2 gear 86 to rotate. The No. 2 gear 8...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap