Real-time cleaning and recycling system for fallen leaves on road surface

A recovery system and technology of fallen leaves, applied in the direction of road cleaning, grain processing, cleaning methods, etc., can solve the problems of low leaf recovery efficiency, difficult leaf recovery, and affecting efficiency, so as to facilitate transmission and aggregation, prevent dust from flying, and prevent self- Flappy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

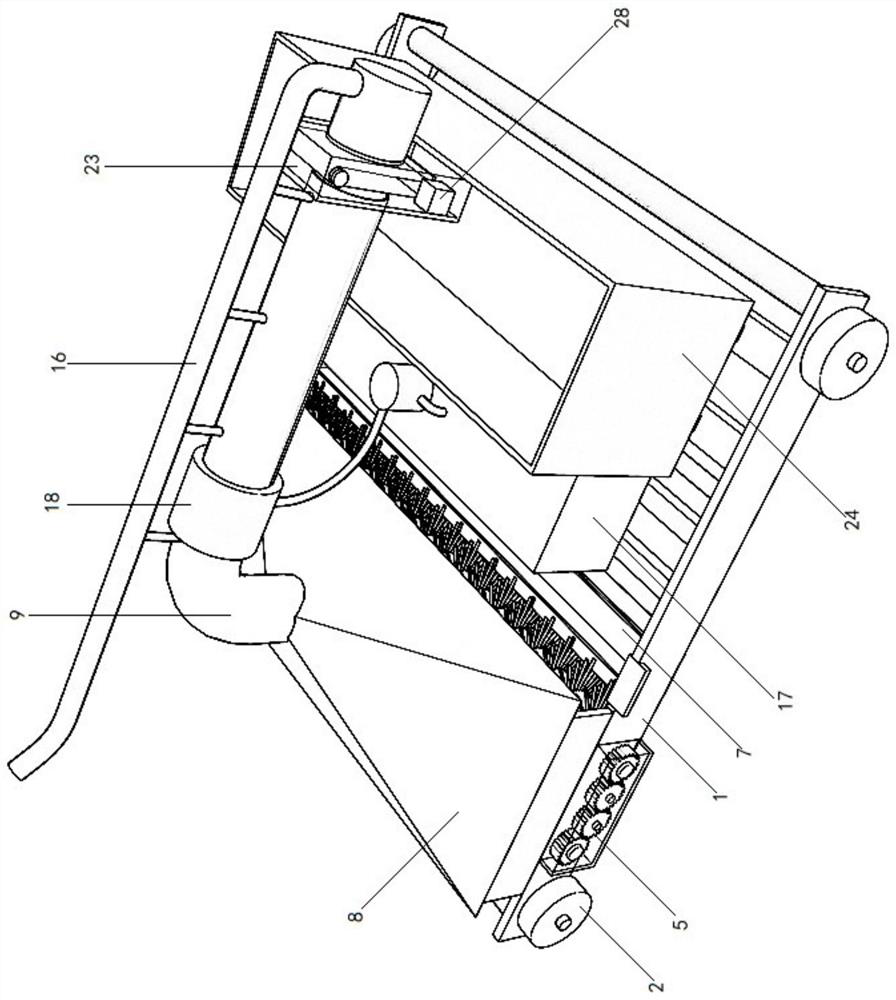

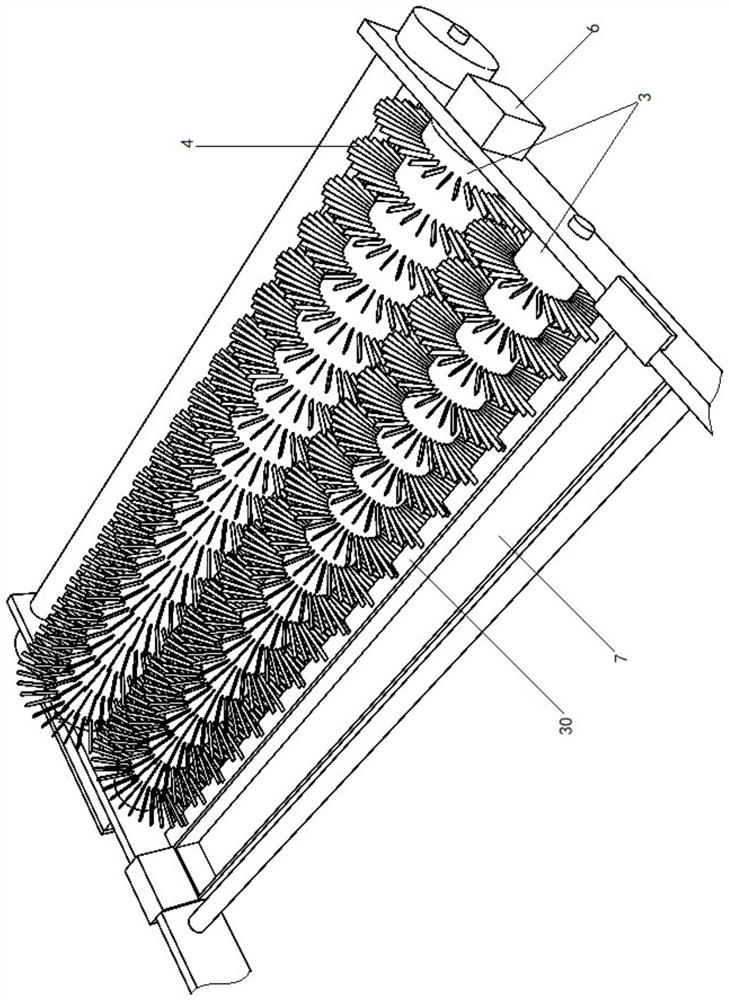

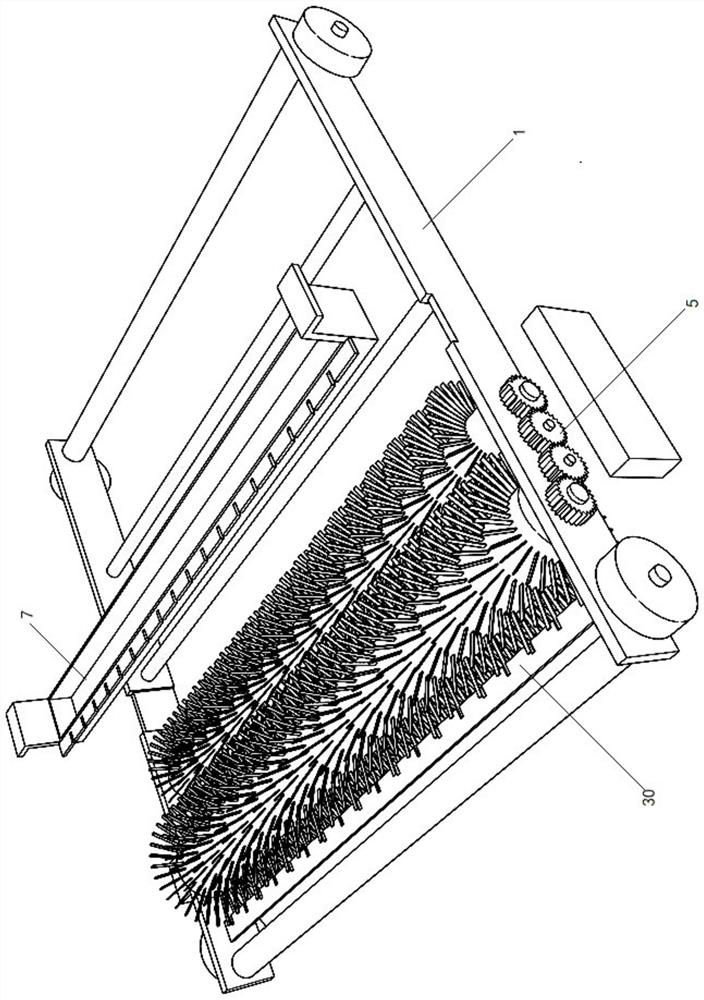

[0027] like Figure 1-3 As shown in the figure, the real-time cleaning and recycling system for road leaves includes a carrier frame 1 and wheels 2 installed on the carrier frame 1. The carrier frame 1 is sequentially provided with a leaf cleaning device, a crushing and conveying device, and a wetting and dust-reducing device from front to back. and a powder slag recovery device; the leaf cleaning device includes two cleaning rollers 3 arranged along the left and right directions; bristles 4 are evenly distributed on the cleaning roller 3; The left and right ends of the cleaning rollers 3 are respectively connected with the left and right sides of the carrying frame 1 for rotation correspondingly; a gear box 5 is installed between the left ends of the two cleaning rollers 3 for synchronous and reverse rotation of the two cleaning roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com