Extensible tree-shaped modular wood structure unit

A wood-structured, modular technology, applied in building construction, drinking water installations, buildings, etc., can solve the problems of long production cycle, unsightly, inconvenient expansion, etc., and achieve the effect of short production cycle and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

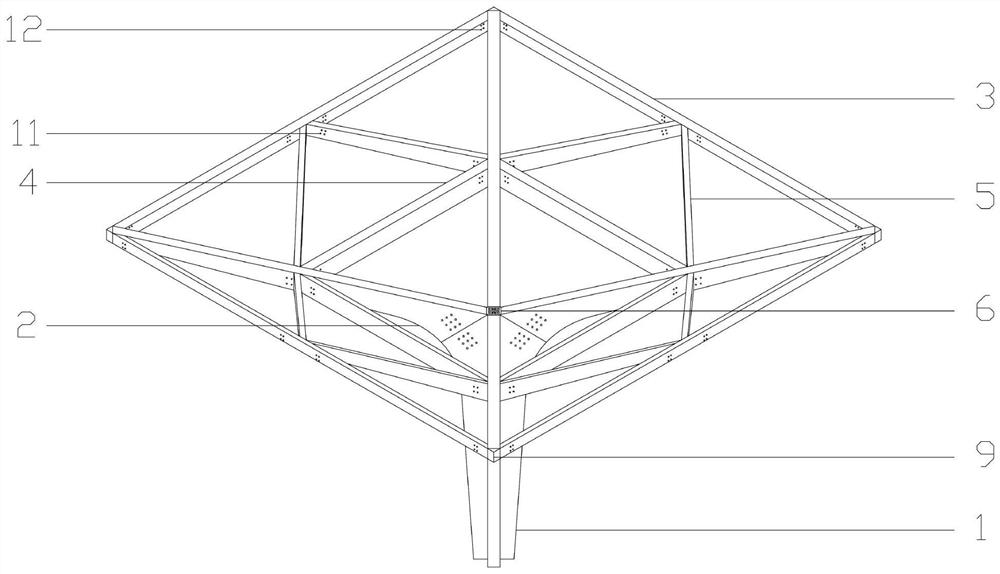

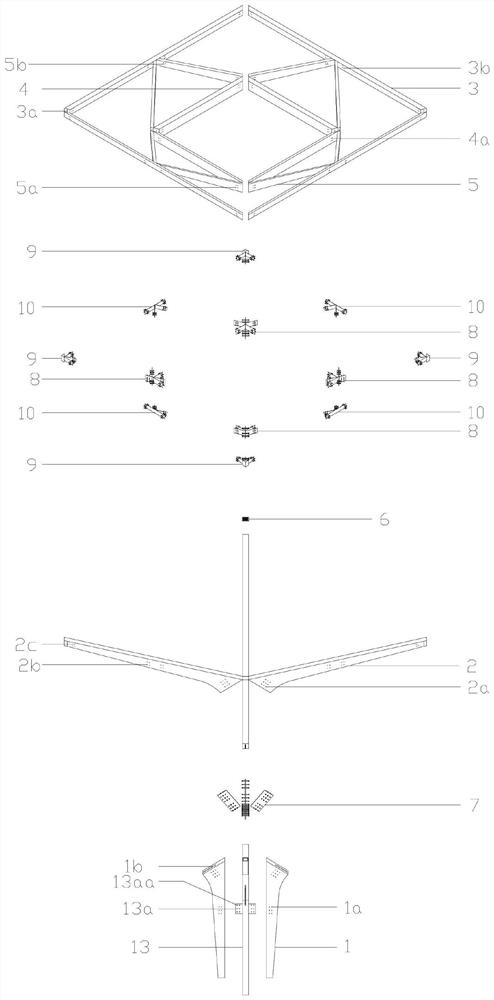

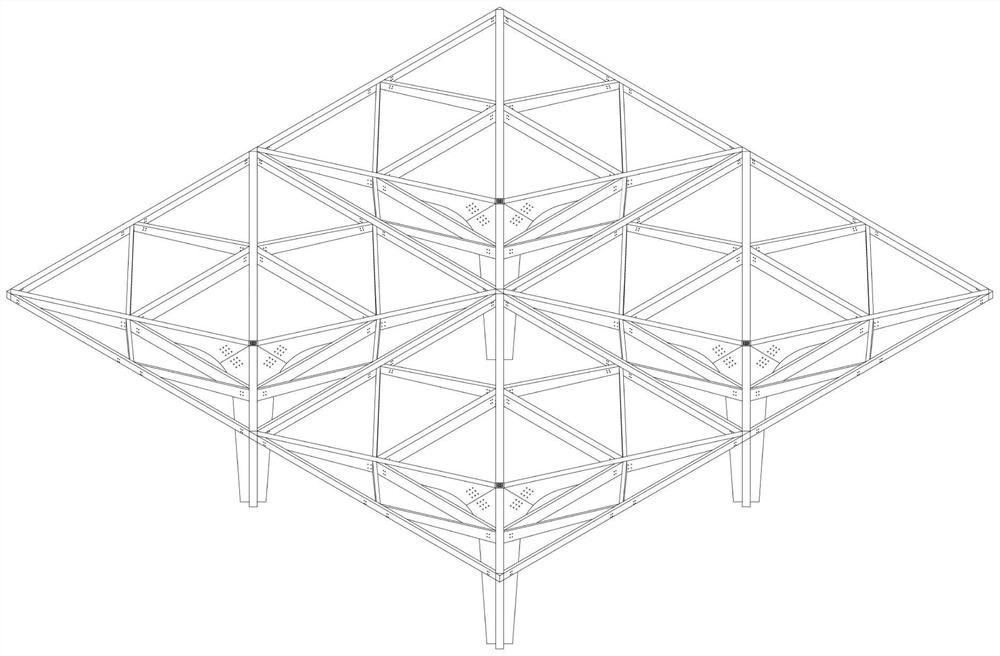

[0045] like Figure 1 to Figure 15 As shown, an expandable tree-shaped modular wood structure unit in this embodiment includes a column 1, a main beam 2, a primary frame beam 4, a secondary frame beam 3, a connecting beam 5, a filter plate 6, a second frame beam A steel sheet 7, a second steel sheet 8, a third steel sheet 9, a fourth steel sheet 10, a bolt 11, a nut 12, and a downpipe 13;

[0046] The top of the column 1 is provided with a first slot 1b for accommodating the bolt 11 and the first steel sheet 7;

[0047] The bottom of the main beam 2 is provided with a second slot 2a for accommodating the bolt 11 and the first steel sheet 7, the first steel sheet 7 is embedded in the second slot 2a, and the fixing column 1 is tightly connected by the bolt 11 and the nut 12. And the main beam 2 to form a single main structure; the bolts and nuts are matched in size.

[0048] Both ends of the first-level frame beam 4 are provided with third notches 4a for accommodating the bolt...

Embodiment 2

[0060] The structure and connection relationship of the present application are described in the second embodiment, and the installation method of the present application is described below.

[0061] During installation, the bottom of the main beam is provided with a second slot for accommodating the bolt and the first steel sheet, the first steel sheet is embedded in the second slot, and the fixed column and the main beam are tightly connected by bolts and nuts to form a single main body structure.

[0062] Four sides of the downpipe are welded with downpipe steel sheets, and the downpipe steel sheets are provided with bolt slots. The downpipe steel sheet is provided with bolt slots, and the column has a tenth slot aligned with the bolt slots in the downpipe steel sheet in the middle of the four sides. It is fixed by bolts and nuts in a hidden and tight connection to form a top installation. Tree-shaped main structure with filter plates.

[0063] The primary frame beam is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com