Dust removal device for tunnel construction

A dust removal device and tunnel construction technology, which is applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of high labor intensity, ineffective effect, and low dust removal efficiency, so as to ensure the overall construction progress, move quickly and conveniently, Wide coverage of dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

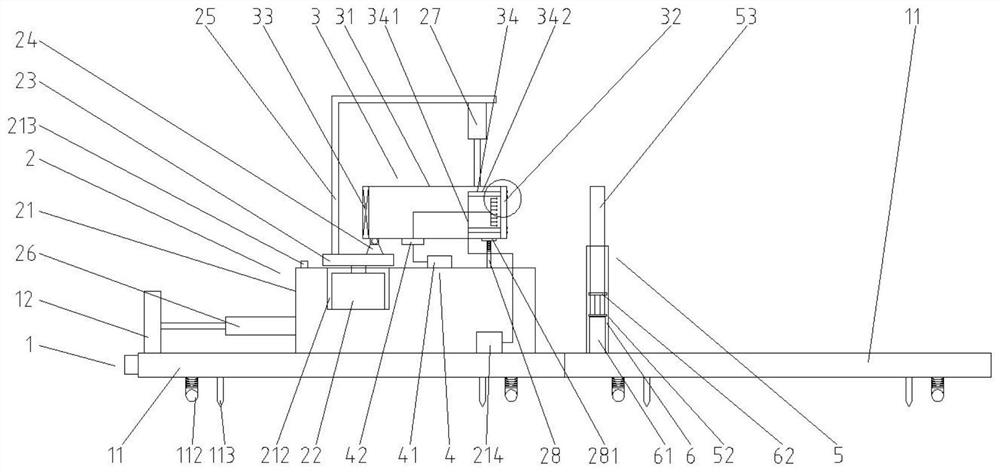

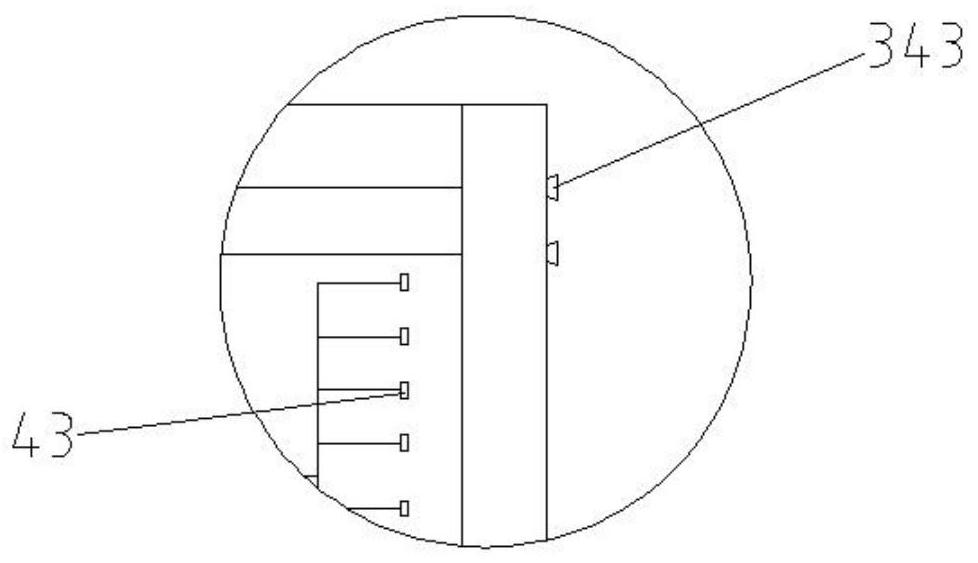

[0035] see Figure 1 to Figure 6 , this embodiment provides a dust removal device for tunnel construction, including a first support assembly 1, a second support assembly 2 and an air extraction and dust removal assembly 3;

[0036] The second support assembly 2 is disposed on the first support assembly 1, and the second support assembly 2 can slide left and right along the first support assembly 1;

[0037] The air extraction and dust removal assembly 3 is fixedly arranged on the second support assembly 2, and the air extraction and dust removal assembly is used for air extraction and dust removal in the tunnel.

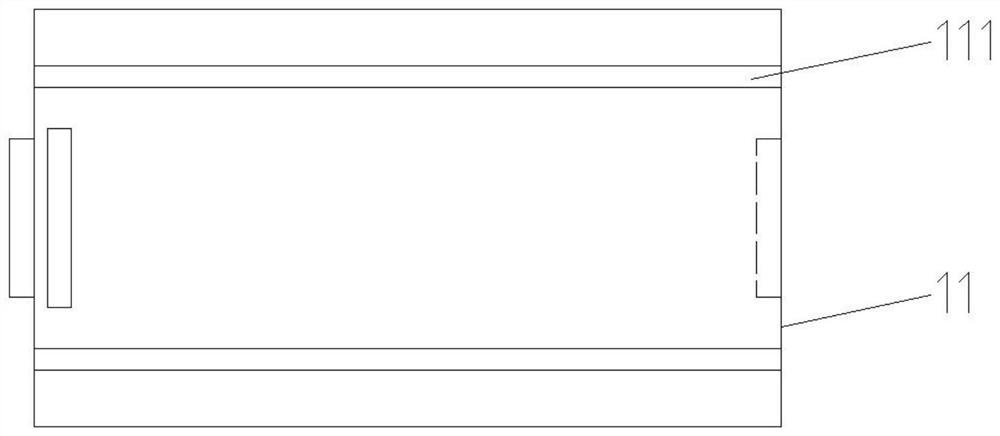

[0038] see Figure 1 to Figure 6 , the first support assembly 1 includes a support plate 11 and a vertical plate 12; the support plates 11 are two and are inserted horizontally, and the upper end of the support plate 11 is provided along the longitudinal direction of the support plate 11. The chute 111; the vertical plate 12 is detachably inserted at the upper lef...

Embodiment 2

[0057] see Figure 7 to Figure 11 The difference between this embodiment and Embodiment 1 is that it also includes a water diversion assembly 7, the water diversion assembly 7 includes a first water diversion plate 71 and a second water diversion plate 72. A third slot (not shown) is arranged symmetrically at the ends, the first water diversion plate 71 is provided with a third plug that matches the third slot, and the second water diversion plate 72 is provided with a The fourth plug that is compatible with the first slot, the first water diversion plate 71 is two and is symmetrically plugged on the front and rear sides of one of the support plates 11, and the second water diversion plate 72 is plugged into the The right side of one of the support plates 11 .

[0058] When the first support assembly 1 is moved close to the tunnel face, the first water guide plate 71 and the second water guide plate 72 are plugged on the front and rear sides and the right end of the support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com