Liquid cooling plate assembly testing fixture

A liquid cold plate and assembly technology, applied in the direction of mechanical diameter measurement, instruments, measuring devices, etc., can solve the problems that cannot meet the production needs of the mass production stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

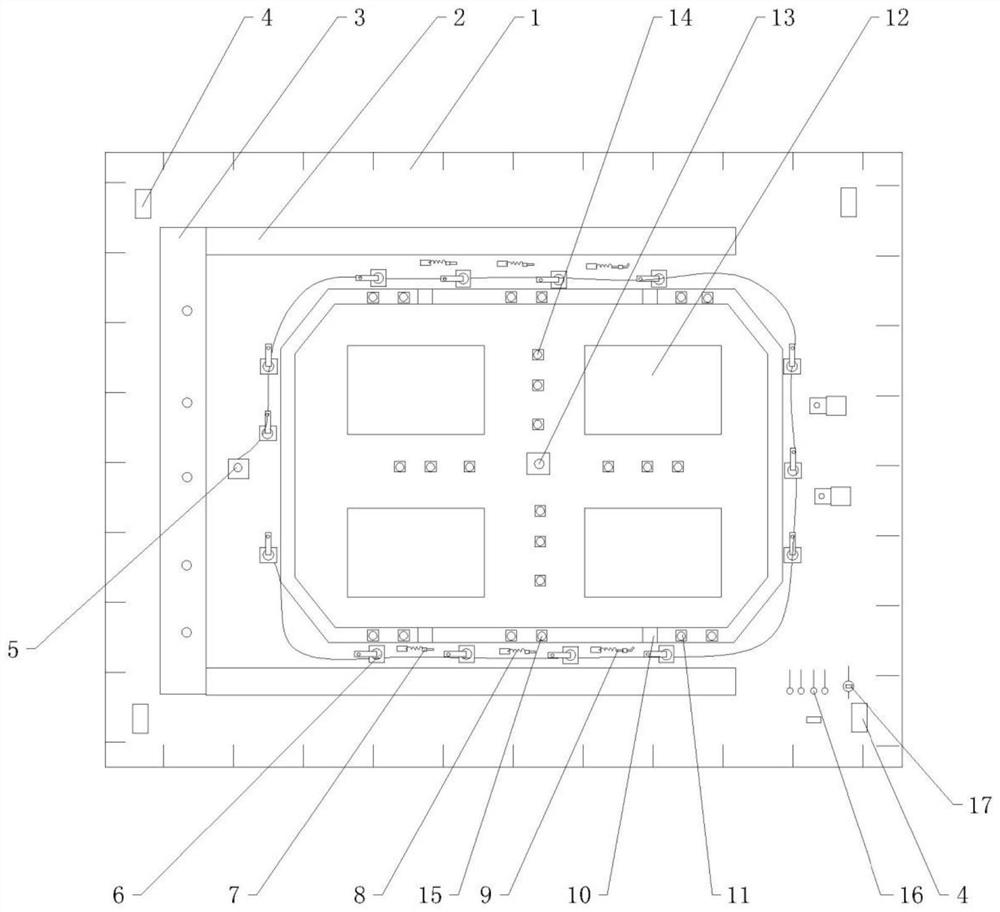

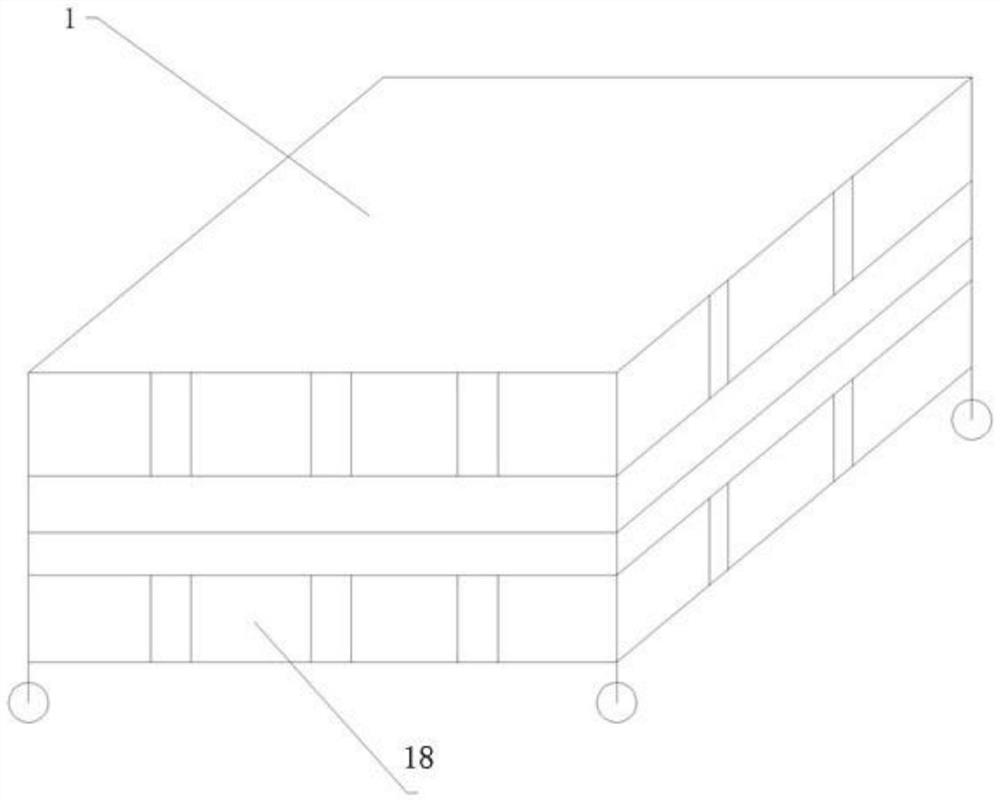

[0023] Example: as attached figure 1 As shown, a liquid-cooled plate assembly inspection tool includes a support platform 1, a support block 12 and a slide rail 2 are arranged on the support platform 1, and a gantry 3 is slidably installed on the slide rail 2, and the gantry 3 and the support block 12 are located in the same position. Correspondingly, the support platform 1 is provided with a lock pin 16 , a detection pin, a cylinder 6 and an air valve 5 .

[0024] Two slide rails 2 are arranged in parallel on both sides of the support platform 1, the support block 12 is located between the two gantry 3, a dial indicator 17 is installed on the gantry 3, and a dial indicator reset seat is installed on the support platform.

[0025] The side of the support platform 1 is equipped with a joint inner diameter pass and stop gauge 8, a joint outer diameter pass and stop gauge 7 and a line profile pass and stop gauge 9, a cylinder 6, an air valve 5, a joint inner diameter pass and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com