Gas collection test system for electric reactor

A test system and reactor technology, applied in the field of transformers, can solve the problems of gas relay alarm delay, increased probability of accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

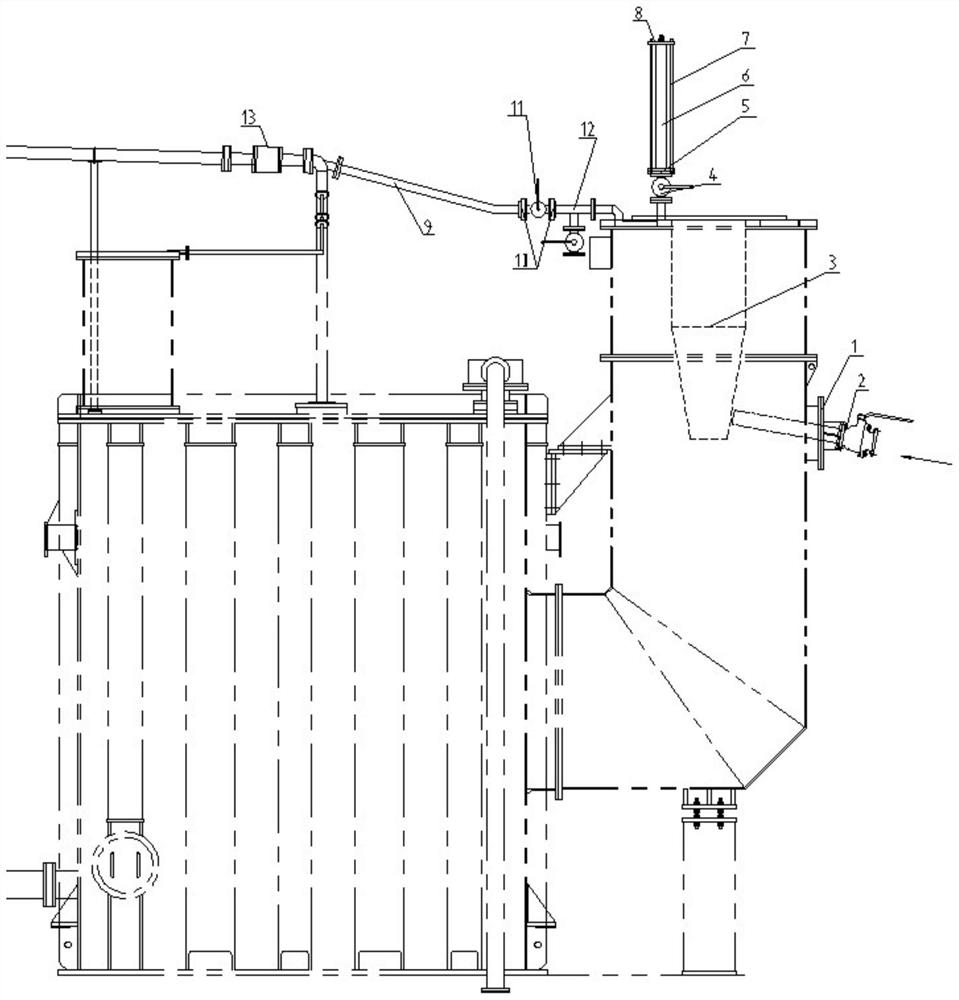

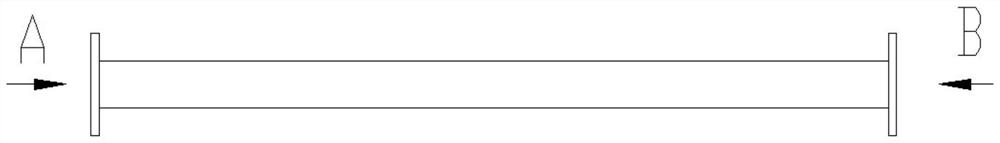

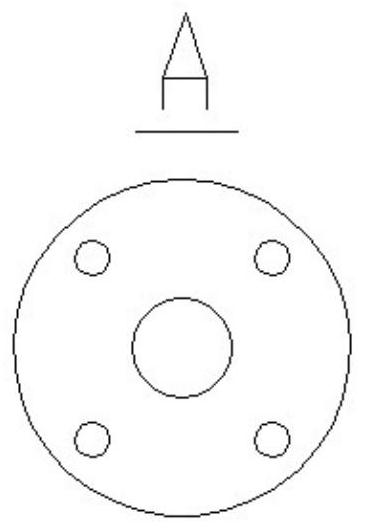

[0041] The embodiment of the present invention provides a reactor gas gathering test system, figure 1 It is a schematic structural diagram of a reactor gas gathering test system according to an embodiment of the present invention; Figure 2-Figure 22 They are the first joint pipe, the second joint pipe, the three-way joint pipe, the cover plate with a plug, the first transition flange, the second transition flange, the screw, the Schematic diagram of the casing replacement part and the cover plate in the intake direction.

[0042] like Figure 1-22 As shown, the embodiment of the present invention provides a reactor gas collection test system, including: an air intake direction cover plate 1, which is arranged on the manhole flange of the detachable lead riser on the high-voltage side of the reactor, and the air intake direction A Φ100 ball valve 2 is installed on the cover plate 1;

[0043] The bushing replacement part 3 is used to replace the original high-voltage bushing...

Embodiment 2

[0052] Embodiments of the present invention provide a Figure 1-22 As shown, the embodiment of the present invention provides a reactor gas collection test system, including: an air intake direction cover plate 1, which is arranged on the manhole flange of the detachable lead riser on the high-voltage side of the reactor, and the air intake direction A Φ100 ball valve 2 is installed on the cover plate 1;

[0053] The bushing replacement part 3 is used to replace the original high-voltage bushing of the reactor. The bushing replacement part 3 is sequentially installed with the first Φ50 ball valve 4, the first transition flange 5, the second joint pipe 6, the screw 7 and the belt. plug cover 8;

[0054] A first joint pipe 9, a second transition flange 10, a second Φ50 ball valve 11 and a three-way joint pipe 12 are arranged in sequence between the pipe joint for gas escape of the upper cover plate of the high-voltage transformer raising seat of the reactor and the main joint p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com