Liquid cooling plate

A liquid cold plate and liquid separation technology, which is applied to electrical components, electrochemical generators, secondary batteries, etc., can solve the problems of uneven cooling temperature control, large temperature difference between inlet and outlet liquid, and large temperature difference of heat source, etc., to reduce the total The effect of long path, low head selection, and system cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

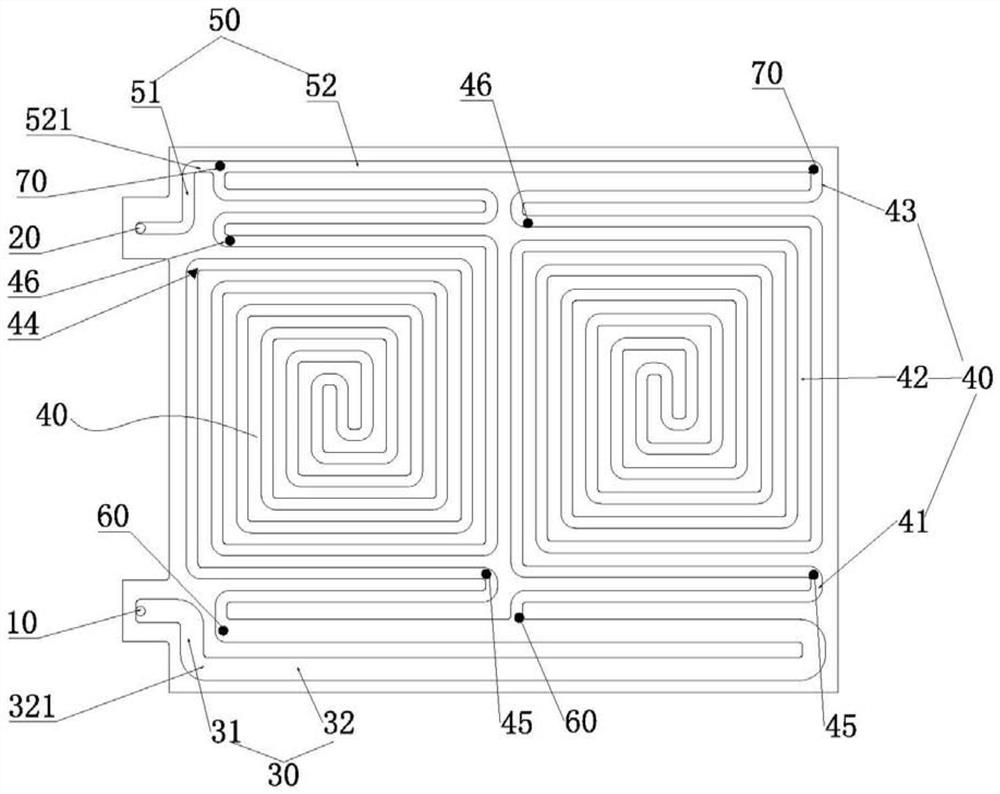

[0045] see figure 1 and Image 6 , figure 1 A liquid cooling plate is shown for cooling battery modules, ref. Image 6 , the battery module includes at least two battery packs 80 arranged along the first direction. In this embodiment, the battery module is formed into a rectangle, the length direction of the battery pack rectangle is the first direction, and the width direction is perpendicular to the first direction. the second direction, Image 6 , each cell group 80 may include 4 cells arranged along the second direction, figure 1 and Image 6 Among them, the first direction is the left-right direction, and the second direction is the up-down direction.

[0046] The liquid-cooling plate is a rectangular structure corresponding to the battery module. The liquid-cooling plate is parallel to the first direction. The left end of the liquid-cooling plate protrudes with two protrusions extending in the first direction, and the two protrusions extend in the second direction. ...

Embodiment 2

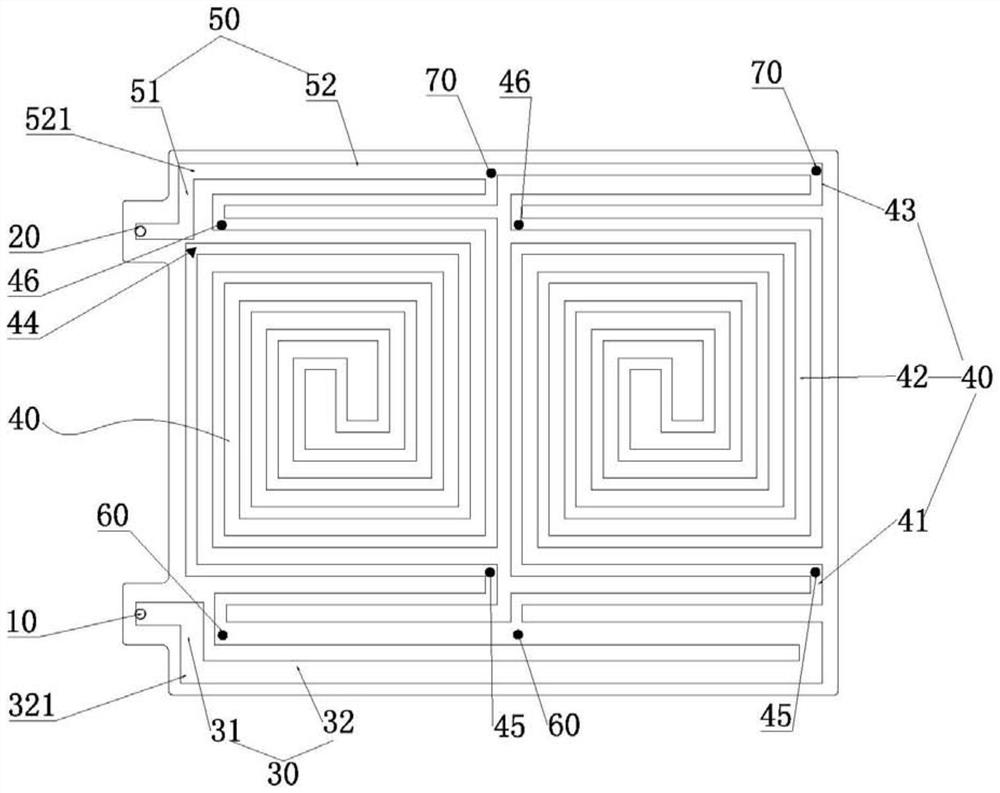

[0059] see figure 2 , the structure of Example 2 is basically the same as that of Example 1, and the number of liquid separation channels 40 is also two. The difference is that the liquid separation outlet 70 is on the same side as the second position 45, and the liquid separation inlet 60 is on the same side as the third position. 46 on the same side, the first segment 41 and the third segment 43 are both Z-shaped structures. In this way, the structure of each liquid separation flow channel 40 is relatively consistent, the structure is more concise, the production process is simple, and it is avoided that the third section 43 is too long and the heat flow is concentrated on the side close to the liquid outlet flow channel 50, and the liquid outlet port 20 is avoided. Temperature is too high.

[0060] The ratio of the length from the first position 44 to the corresponding liquid separation inlet 60 to the length from the first position 44 to the corresponding liquid separati...

Embodiment 3

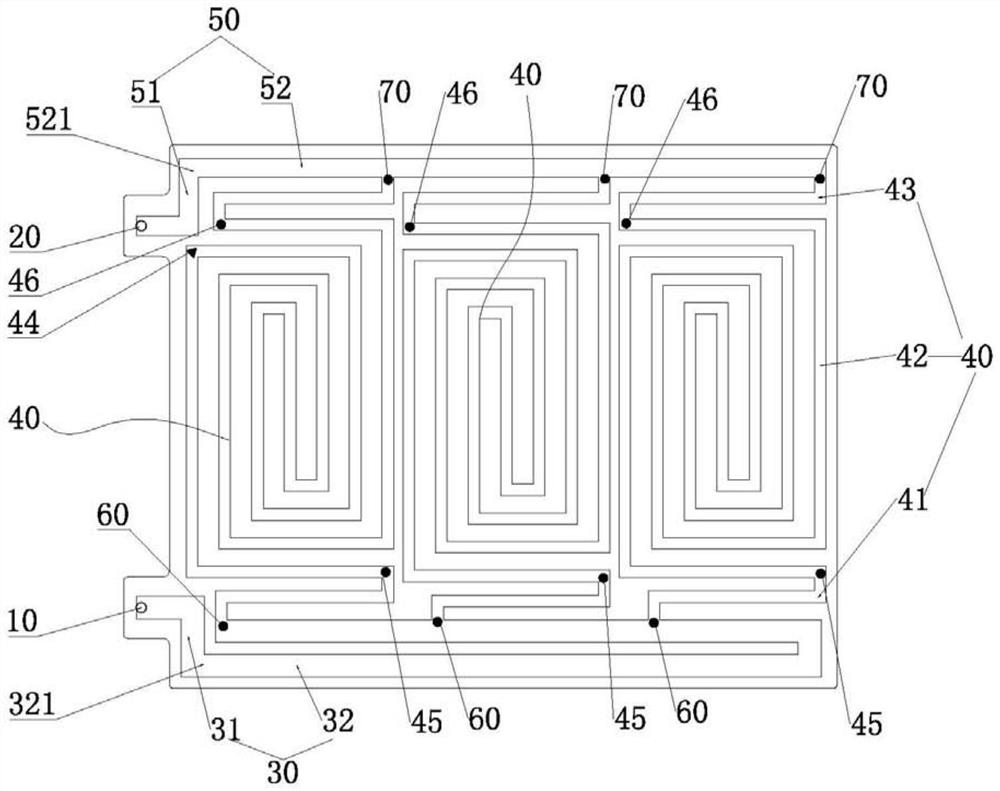

[0063] see image 3 , the structure of Example 3 is basically the same as that of Example 2, the difference is that the number of liquid separation channels 40 is three, and the length from the first position 44 to the corresponding liquid separation inlet 60 is the same as the first position 44 to the corresponding liquid separation inlet 60. The ratio of the length of the liquid separation outlet 70 is 1:1.8.

[0064] In addition, under the condition that the area of the liquid cooling plate remains unchanged, in the arrangement of the three liquid-separating flow channels 40, the zigzag coiled structure is more sparse than the zigzag coiled structure of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com