FPC flexible circuit board integrated processing device and use method thereof

A technology for flexible circuit boards and processing devices, applied in the direction of conductive pattern formation, etc., can solve the problems of production environment damage, inability to discharge waste residue, and abandonment of flexible circuit boards, and achieve the effects of ensuring gold leaching efficiency, saving resources, and protecting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following:

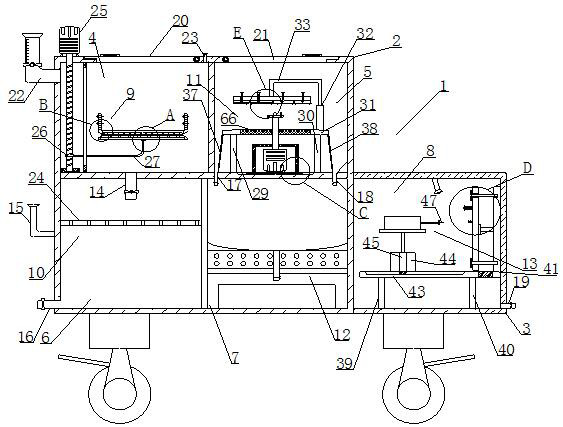

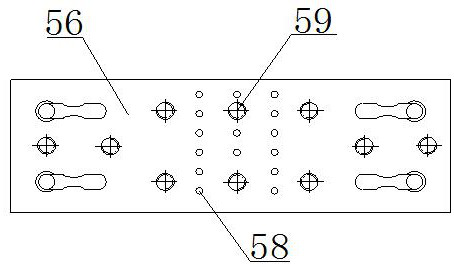

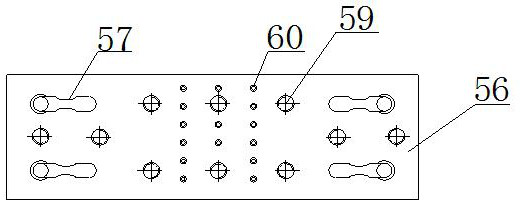

[0042] like Figures 1~10 As shown, an FPC flexible circuit board integrated processing device includes a processing device body 1, the processing device body 1 includes a processing box body 1 2 and a processing box body 2 3, and the processing box body 1 2 is arranged in the processing box body 2 3 Above, the processing box body 2 is provided with a first cavity 4 and a second cavity 5, and the processing box body 2 is provided with a third cavity 6, a fourth cavity 7 and a fifth cavity 8. The processing box body The length of the first 2 is less than the length of the processing box 2 3, the chemical gold leaching device 9 and the filtration treatment device 10 are arranged between the first cavity 4 and the third cavity 6, and the second cavity 5 and the fourth cavity 7 A surface pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com