Rubber composition and vulcanized molded article

A rubber composition, vulcanization molding technology, applied in other chemical processes, chemical instruments and methods, mechanical equipment, etc., can solve the problems of electrical insulation and kneading processability that are not mentioned, and achieve excellent kneading processability, Effects of good compression set properties, excellent low temperature properties and electrical insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

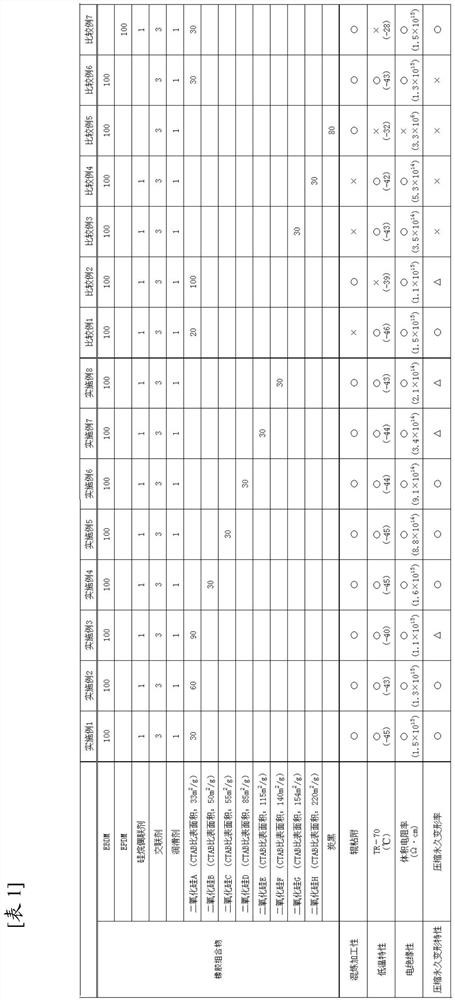

[0063] 100 parts by weight of EBDM (iodine value: 16 (g / 100), trade name "EBT K-9330M", manufactured by Mitsui Chemicals Co., Ltd.), silica A (trade name "Nipsil E74P") were mixed with an open roll kneader. , manufactured by Tosoh Silica Co., Ltd.) 30 parts by weight, a silane coupling agent (trade name "A171", manufactured by Momentive Corporation) 1 weight part, a crosslinking agent (trade name "ParkMill D", manufactured by NOF Corporation) 3 Parts by weight and 1 part by weight of a lubricant (trade name "Diamid 0-200T", manufactured by Nippon Kasei Corporation) were kneaded to prepare a rubber composition.

[0064]

[0065] With respect to the obtained rubber composition, the kneading processability was evaluated based on the adhesion to the surface of the kneader. If kneading was stably possible, it was rated as "○", and if the rubber composition adhered to the surface of the kneader so much that kneading could not be continued, it was rated as "x". The results are sho...

Embodiment 2

[0073] A rubber composition and a vulcanized molded product thereof were prepared in the same manner as in Example 1, except that the blending amount of silica A was 60 parts by weight, and the aforementioned measurements and evaluations were performed. The results are shown in Table 1.

Embodiment 3

[0075] A rubber composition and its vulcanizate molded article were prepared in the same manner as in Example 1, except that the blending amount of silica A was 90 parts by weight, and the above-mentioned measurements and evaluations were performed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com