Copolymer rubber, rubber composition and rubber molding

A copolymer and rubber technology, applied in the field of rubber molding, can solve problems such as inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

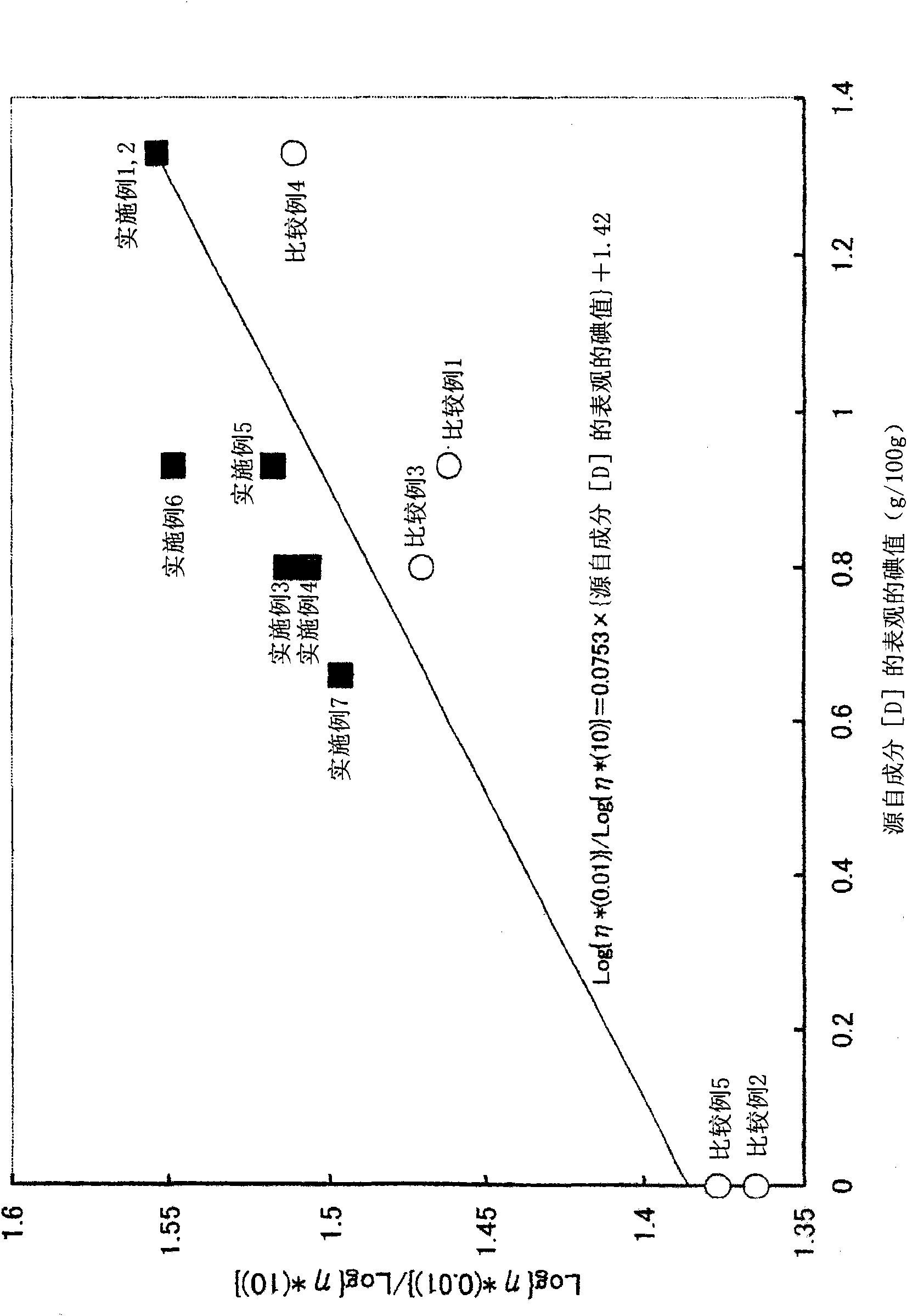

[0245] Using a polymerizer with a stirring blade of 300 L in volume, the reaction is carried out continuously at 80° C. from ethylene as component [A], propylene as component [B], and 5-ethylene-2-ethylene as component [C]. Quaternary copolymerization reaction of norbornene (ENB) and 5-vinyl-2-norbornene (VNB) as component [D].

[0246] Using hexane (final concentration: 90.8% by weight) as a polymerization solvent, ethylene, propylene, ENB, and VNB were continuously supplied so that the ethylene concentration was 3.1% by weight, the propylene concentration was 4.6% by weight, the ENB concentration was 1.4% by weight, and the VNB concentration was 0.11% by weight.

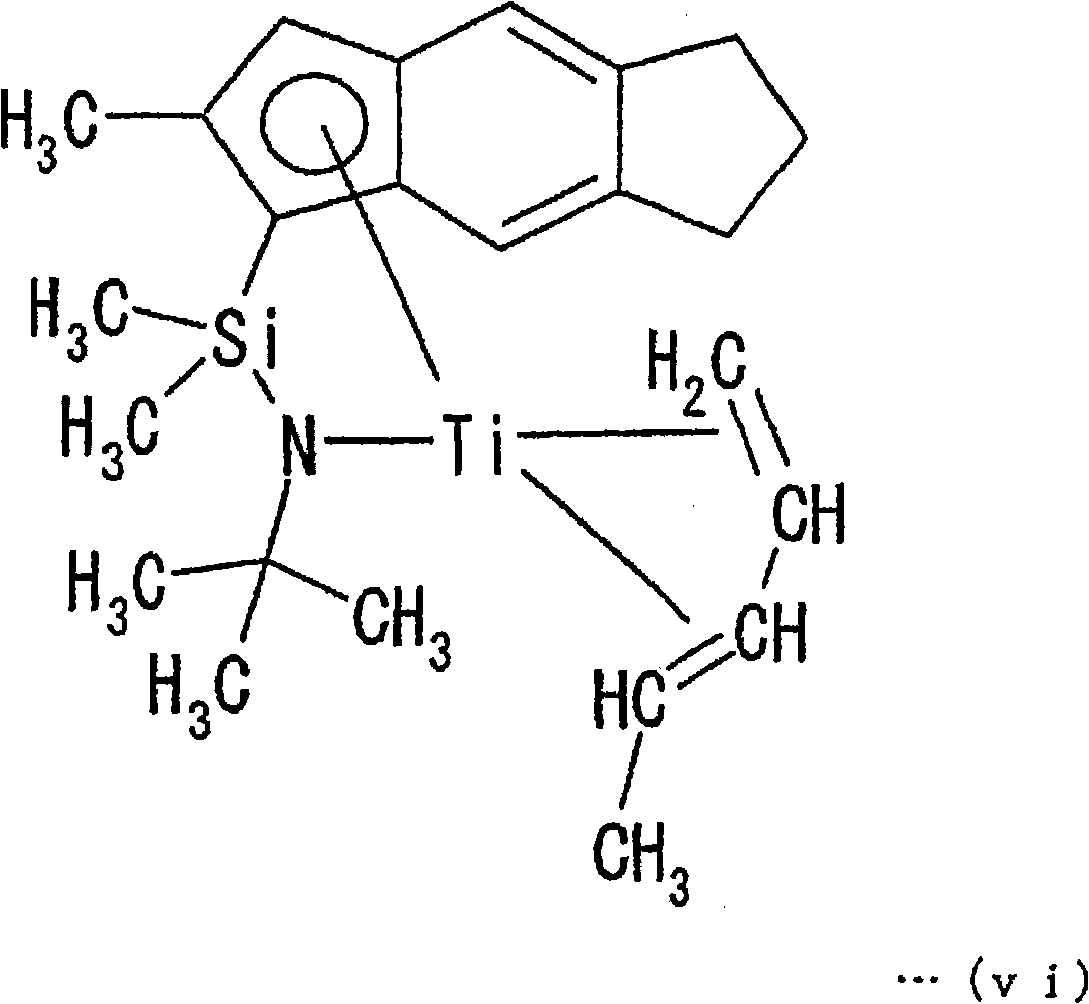

[0247] While keeping the polymerization pressure at 0.8MPa, as the main catalyst, use the metallocene catalyst [N-(1,1-dimethylethyl)-1,1-dimethyl Base-1-[(1,2,3,3A,8A-n)-1,5,6,7-tetrahydro-2-methyl-S-benzobiinden-1-yl]aminated silane ( 2-)-κN][(1,2,3,4-η)-1,3-pentadiene]-titanium was supplied continuously so as ...

Embodiment 2~7

[0250] According to the polymerization conditions described in Table 1, a copolymer rubber was obtained in the same manner as in Example 1. Table 1 shows the physical properties of the obtained copolymer rubber.

Embodiment 8

[0295] The rubber composition and tubular sponge of the present invention are obtained by the production method described below. First, the rubber composition before vulcanization and foaming in the rubber composition of the present invention was mixed using MIXTRONBB MIXER (manufactured by Kobe Steel Works, BB-4 type, volume 2.95L, rotor 4WH), and kneaded as follows: Substances: With respect to 100 parts by weight of the copolymer rubber obtained in Example 1, 5 parts by weight of "META-Z102" (trade name; manufactured by Inoue Lime Industry Co., Ltd.) as a vulcanization aid, stearin as a processing aid 2 parts by weight of acid, 2 parts by weight of "Arquad2HF" (trade name; produced by Lion Akzo Co., Ltd.) as an activator, 120 parts by weight of "Asahi #55G" (trade name, produced by Asahi Carbon Co., Ltd.) as a reinforcing agent , 55 parts by weight of "Whiten SB" (trade name, produced by Shiraishi Calcium Co., Ltd.) as an inorganic filler, and "Diana Process Oil PS-430" (tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com