Additive for fast water injection of strong hydrophobic coal roadway short hole and preparation method of additive

An additive and hydrophobic technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex use process, poor wetting effect of strongly hydrophobic coal roadway, unsuitable for large-scale application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

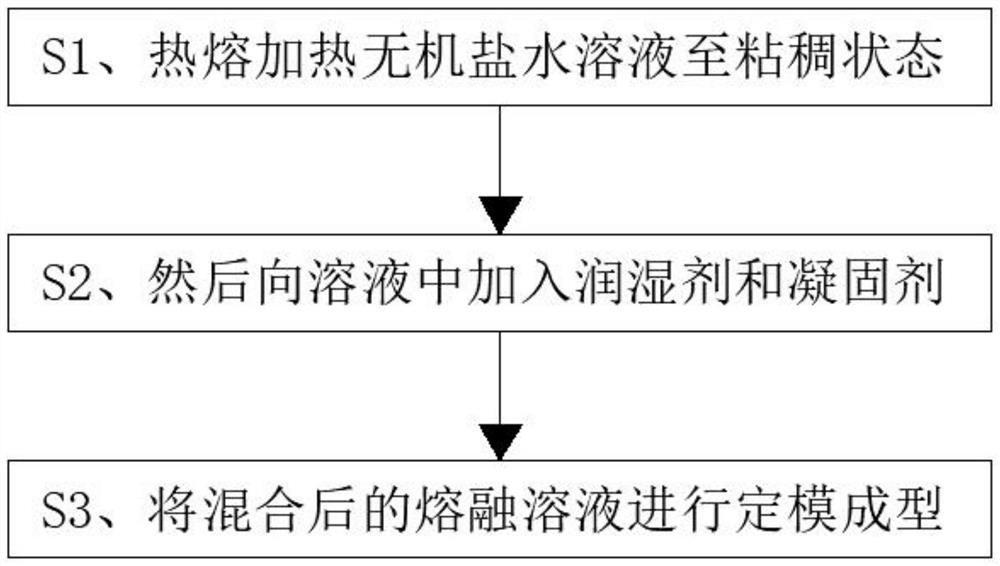

[0050] A preparation method for a short-hole rapid water injection additive for a strong hydrophobic coal roadway, comprising the following method steps:

[0051] S1. Heat the inorganic salt solution by hot melting to a viscous state: first, put a small amount of water in a beaker, place the beaker on a closed electric furnace, boil the water, add inorganic salt, and boil the inorganic salt solution to a viscous state;

[0052] S2. Then add a wetting agent and a coagulant to the solution: first add a wetting agent to the inorganic salt solution, and then add a quantitative amount of octylphenyl polyoxyethylene ether and a-alkenyl sodium sulfonate to it. The stick is stirred slowly in one direction until the formula is well mixed;

[0053] S3. Mold the mixed molten solution: quickly pour the mixed solution into the mold, put it in a cool place, wait for 2 hours, and then release the mold.

[0054] In the above implementation process, the inorganic salt can be effectively disso...

Embodiment 1

[0060] A fast water injection additive for short holes in strong hydrophobic coal lanes and a preparation method thereof, in terms of mass percentage, comprises: 3% of wetting agent, 97% of coagulant, and is prepared as a solid additive through a thermal synthesis process.

[0061] The specific steps are:

[0062] 1) First, put a small amount of water in a beaker, put the beaker on a closed electric furnace, boil the water, add 97g of inorganic salt, and boil the inorganic salt solution to a viscous state;

[0063] 2) Add calcium chloride to the inorganic salt solution, then add 3g of the compound solution of octylphenyl polyoxyethylene ether and sodium a-alkenyl sulfonate, and slowly stir with a glass rod in one direction until the formula is mixed uniform;

[0064] 3) Pour the formula into the mold quickly, put it in a cool place, wait for 2 hours, and then release the mold, and the preparation of the additive for rapid water injection in the short hole of the strong hydrop...

Embodiment 2

[0066] The invention discloses an additive for fast water injection with short holes in strong hydrophobic coal lanes and a preparation method thereof. In mass percentage, the additive comprises: 5% of wetting agent, 95% of coagulant, and is prepared into a solid additive formula through a thermal synthesis process.

[0067] The specific steps are:

[0068] 1) First, put a small amount of water in a beaker, put the beaker on a closed electric furnace, boil the water, add 95g of inorganic salt, and boil the inorganic salt solution to a viscous state;

[0069] 2) Add calcium chloride to the inorganic salt solution, then add 5g of the compound solution of octylphenyl polyoxyethylene ether and a-alkenyl sodium sulfonate, and slowly stir with a glass rod in one direction until the formula is mixed uniform;

[0070] 3) Pour the formula into the mold quickly, put it in a cool place, wait for 2 hours, and then release the mold, and the preparation of the additive for rapid water inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com