Super-strong cleaning decontamination cut pile electric appliance rolling brush cleaning cloth and manufacturing method thereof

A manufacturing method and technology for cleaning cloth, which are applied in the direction of double-sided pile fabric cutting, machine parts, textiles and paper making, etc. Round and smooth, low cost, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

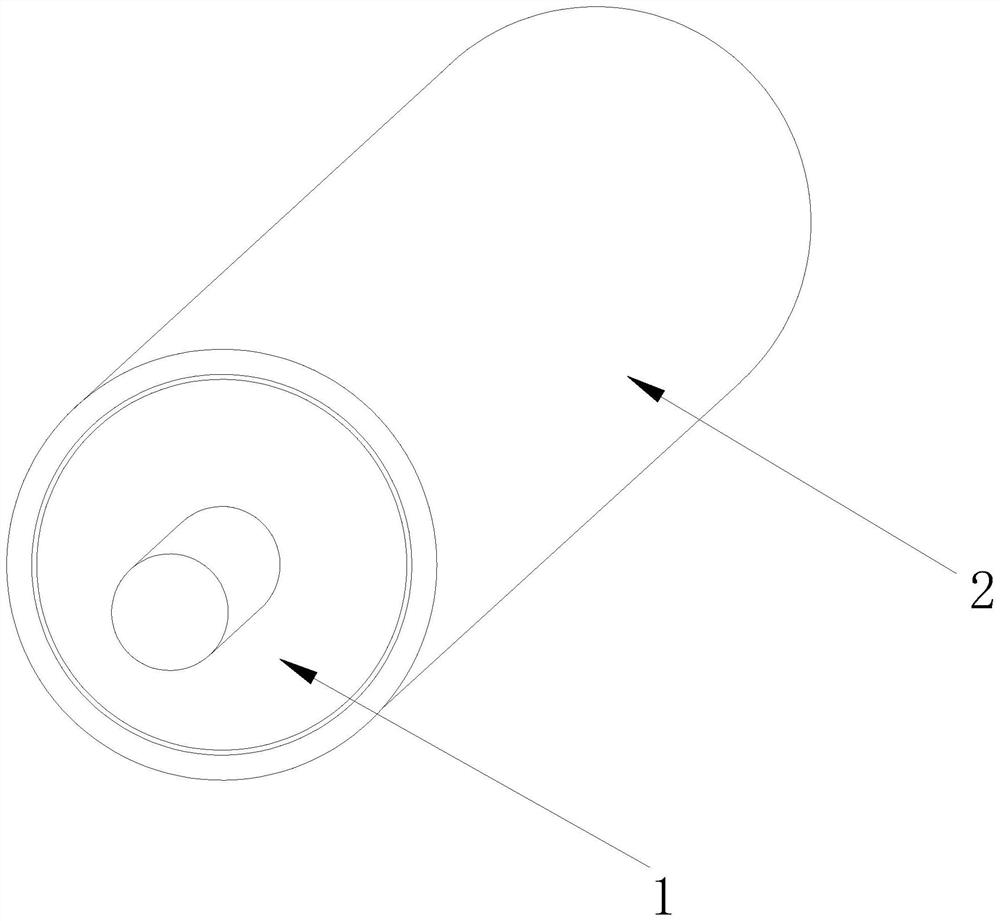

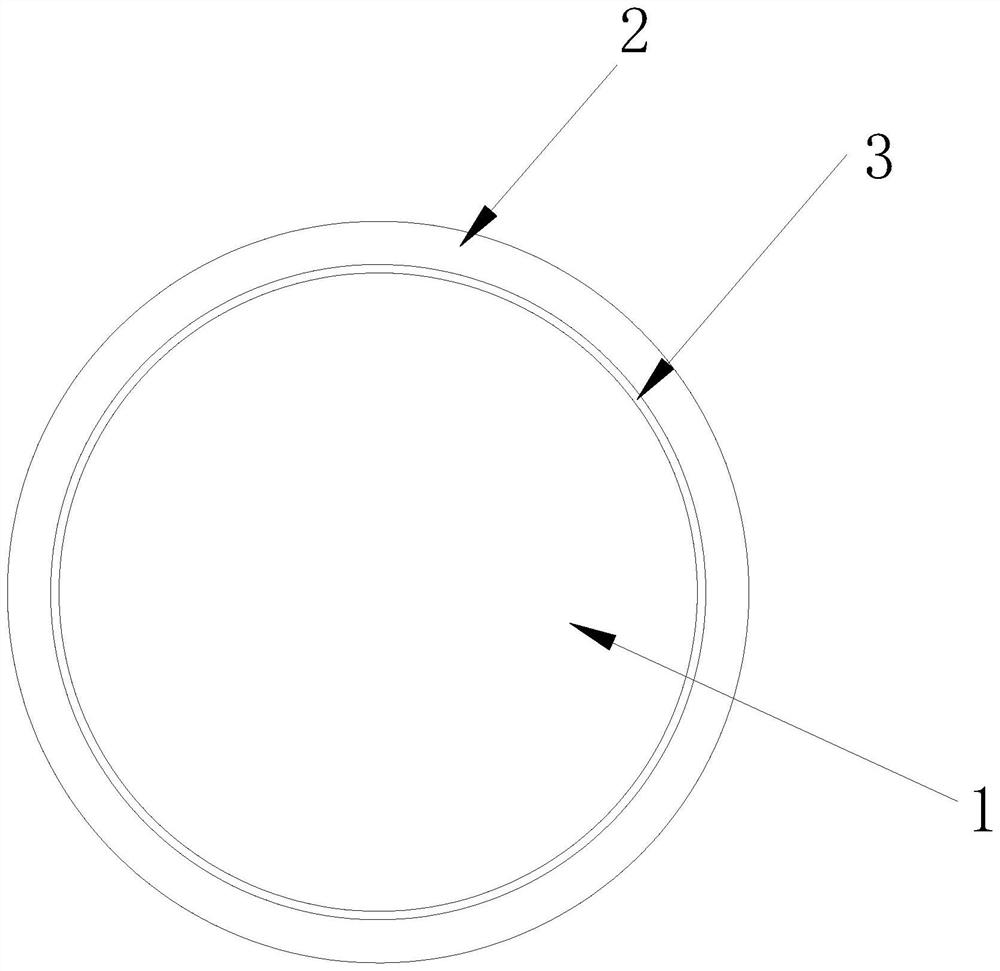

[0033] see Figure 1-4 As shown, a super-strong cleaning and decontamination cutting lint electric appliance rolling brush cleaning cloth includes a brush roller 1, a cleaning cloth layer 2 and an adhesive layer 3;

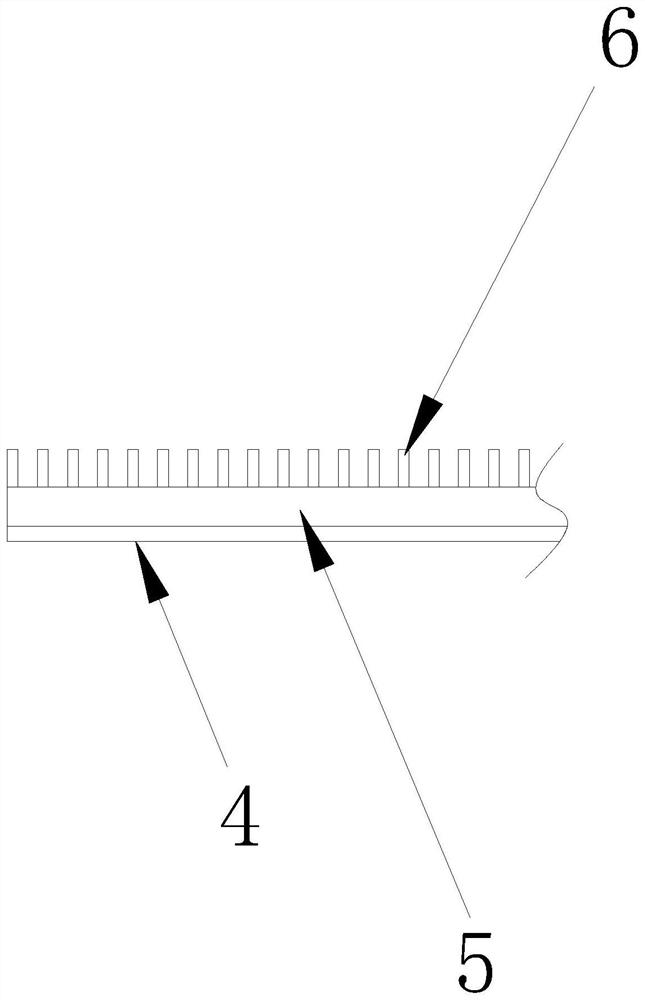

[0034] The outer surface of the brush roll 1 is compounded and fixed with an adhesive layer 3 through an adhesive layer 3. The adhesive layer 3 includes a bottom yarn layer 4, a fluff layer 5 and a hard wire 6. The bottom yarn layer 4 and The fluff layers 5 are interwoven and fixed, and hard wires 6 are evenly fixed on the fluff layers 5 .

[0035] Further, the manufacturing method of the super strong cleaning and decontamination cutting lint electric brush roller cleaning cloth comprises the following steps:

[0036] 1. The raw materials are processed, warped, and weaved by double rapier looms to form semi-finished products A;

[0037] 2. Iron the semi-finished product A to form the semi-finished product B;

[0038] 3. Coating the semi-finished product B;

[...

Embodiment 2

[0049] see Figure 1-4 As shown, a super-strong cleaning and decontamination cutting lint electric appliance rolling brush cleaning cloth includes a brush roller 1, a cleaning cloth layer 2 and an adhesive layer 3;

[0050] The outer surface of the brush roll 1 is compounded and fixed with an adhesive layer 3 through an adhesive layer 3. The adhesive layer 3 includes a bottom yarn layer 4, a fluff layer 5 and a hard wire 6. The bottom yarn layer 4 and The fluff layers 5 are interwoven and fixed, and hard wires 6 are evenly fixed on the fluff layers 5 .

[0051] Further, the manufacturing method of the super strong cleaning and decontamination cutting lint electric brush roller cleaning cloth comprises the following steps:

[0052] 1. The raw materials are processed, warped, and weaved by double rapier looms to form semi-finished products A;

[0053] 2. Iron the semi-finished product A to form the semi-finished product B;

[0054] 3. Coating the semi-finished product B;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com