Process for producing wax products

A technology of wax products and crafts, which is applied in preparations for dressing, medical preparations containing active ingredients, cosmetic preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Example

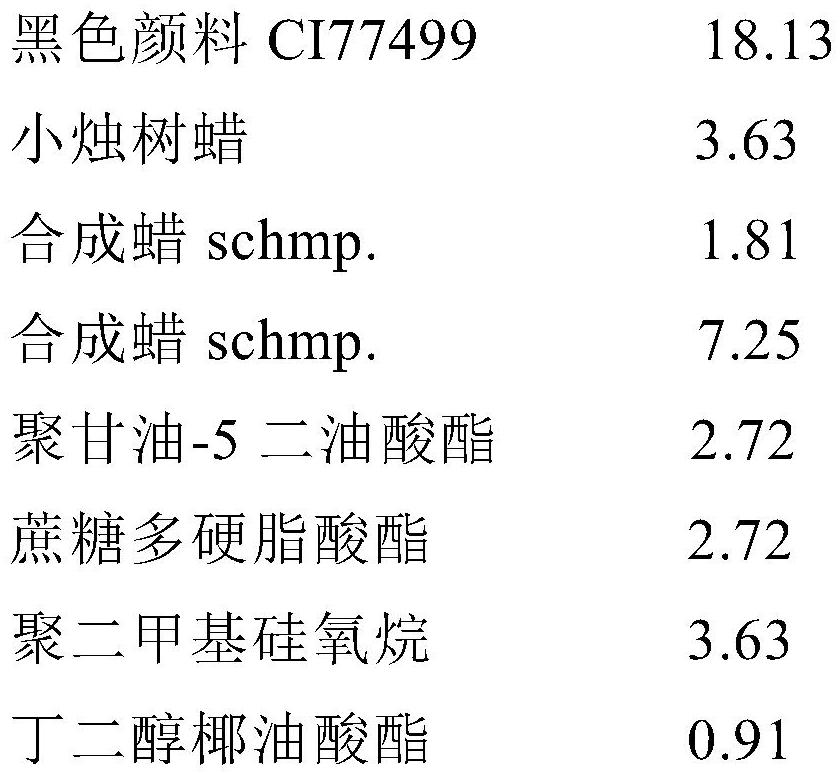

[0075] An article suitable for use as a refill material is produced. The ingredients are shown in the table below, the amounts in each case are mass percent (relative to the mass of the total composition).

[0076] Phase A

[0077]

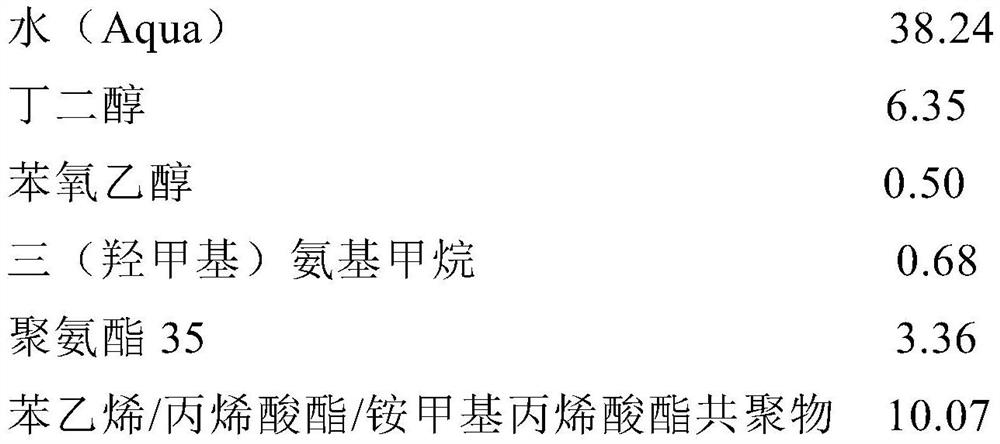

[0078] Phase B

[0079]

[0080] To create the article, candelilla wax and two synthetic waxes were mixed with dimethicone, followed by addition of oleyl butylene glycol cocoate, followed by polyglycerol 5 dioleate, and sucrose polystearin The acid ester acts as an emulsifier and the resulting mass is heated to produce a molten wax phase. The molten mass is then homogenized with the black pigment. In this way, the wax phase A was obtained. The polyurethane and styrene / acrylate / ammonium methacrylate copolymer were then mixed together as a 40% aqueous dispersion each, and phenoxyethanol was added as a preservative. Tris(hydroxymethyl)aminomethane was also added to adjust the pH. The aqueous phase was then heated to a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com