Environment-friendly fluorine-containing aqueous film-forming fire extinguishing agent as well as preparation method and application thereof

An aqueous film-forming and fire extinguishing agent technology, applied in fire prevention equipment, etc., can solve the problems of no sulfonated kerosene fire extinguishing agent, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of environment-friendly fluorine-containing aqueous film-forming fire extinguishing agent comprises the following steps:

[0044] Step 1: mix short-chain fluorocarbon surfactant and hydrocarbon surfactant in proportion, then add water and stir to obtain system I;

[0045] Step II: add a foaming agent and a foam stabilizer to the system I, stir evenly, and heat up to 50-60° C. to obtain the system II;

[0046]Step III: adding a cosolvent to the system II, stirring uniformly, adding an anti-burning agent and stirring to obtain the system III;

[0047] Step IV: after cooling the system III to room temperature, add antifreeze and preservative, stir evenly to obtain the finished product.

[0048] The application of the prepared environment-friendly fluorine-containing aqueous film-forming fire extinguishing agent in the fire extinguishing of the hydrometallurgical extractant.

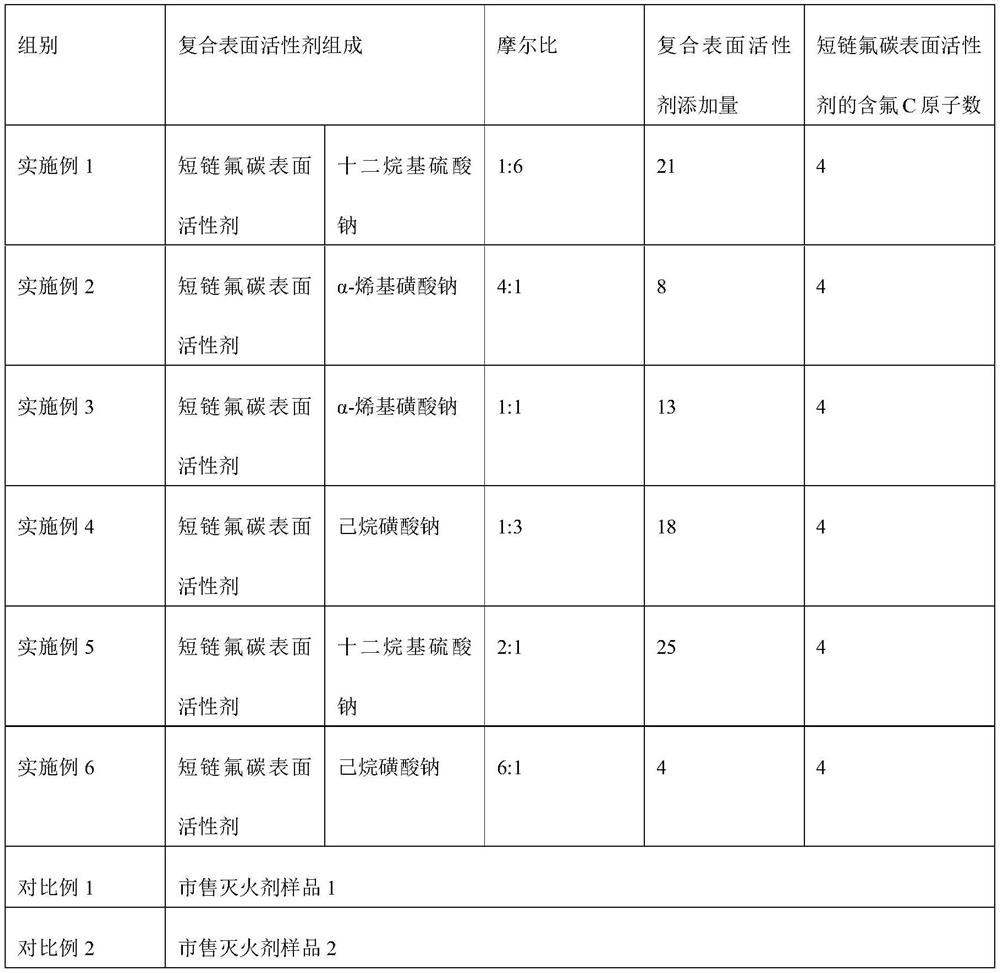

Embodiment 1

[0050] The preparation method of the environment-friendly fluorine-containing aqueous film-forming fire extinguishing agent in this embodiment includes the following steps:

[0051] Step 1: the short-chain fluorocarbon surfactant and sodium lauryl sulfate are compounded according to the molar ratio of 1:6, totaling 21 parts, then adding the remaining water and stirring; wherein the fluorine-containing short-chain fluorocarbon surfactant The number of C atoms is 4;

[0052] Step II: add 2.5 parts of cocamidopropyl betaine and 1.5 parts of lauryl amidopropyl amine oxide, stir evenly;

[0053] Step III: heat up to 50°C, add 1.8 parts of urea, after stirring evenly, slowly add 0.005 part of xanthan gum, and stir evenly;

[0054] Step IV: After cooling down to room temperature, add 0.6 part of propylene glycol butyl ether and 2 parts of sodium hydrogen diacetate, and stir evenly to obtain the environment-friendly fluorine-containing water film-forming fire extinguishing agent prod...

Embodiment 2

[0056] The preparation method of the environment-friendly fluorine-containing aqueous film-forming fire extinguishing agent in this embodiment includes the following steps:

[0057] Step 1: the short-chain fluorocarbon surfactant and sodium α-alkenyl sulfonate are compounded according to the molar ratio of 4:1, totaling 8 parts, then adding the rest of the water and stirring; wherein the short-chain fluorocarbon surfactant contains The number of fluorine C atoms is 4;

[0058] Step II: add 1.6 parts of sodium carboxymethyl cellulose and 2 parts of coconut oil diethanolamide, stir evenly;

[0059] Step III: heating up to 52°C, adding 1.3 parts of urea, stirring uniformly, slowly adding 0.04 part of polyethylene glycol, stirring uniformly;

[0060] Step IV: After cooling to room temperature, add 0.4 part of propylene glycol butyl ether and 1.8 part of sodium hydrogen diacetate, and stir evenly to obtain the environmentally friendly fluorine-containing water film-forming fire ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap