Convenient-to-disassemble MBR (Membrane Bioreactor) membrane module, disassembling and washing method, water treatment device and water treatment method

A membrane unit and membrane unit technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of inconvenience in overall hoisting, achieve convenient disassembly and installation, and ensure filtration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] When the existing MBR membrane packer uses off-line membrane washing in the integrated membrane box, it needs to be hoisted out as a whole for cleaning or manually removed from the tank for cleaning. It also consumes manpower and operates in a limited space throughout the process, and there are certain safety hazards. Furthermore, according to the disassembly requirements of the existing MBR membrane assembly, a distance of a membrane is reserved in the box body during design and manufacture, which occupies the volume of the box body, so that the volume and weight of the box body increase accordingly. , the hoisting difficulty increases. In order to solve the problems existing in the prior art, the present application provides a convenient detachable MBR membrane stacker, so as to reduce the cleaning difficulty of the MBR membrane stacker and solve the problem of time-consuming and laborious overall hoisting.

[0047] The present application provides an easily detachab...

Embodiment 2

[0057] This embodiment of the present application provides a method for disassembling and washing the easily disassembled MBR membrane assembly provided in the first embodiment. The method can be briefly described as follows:

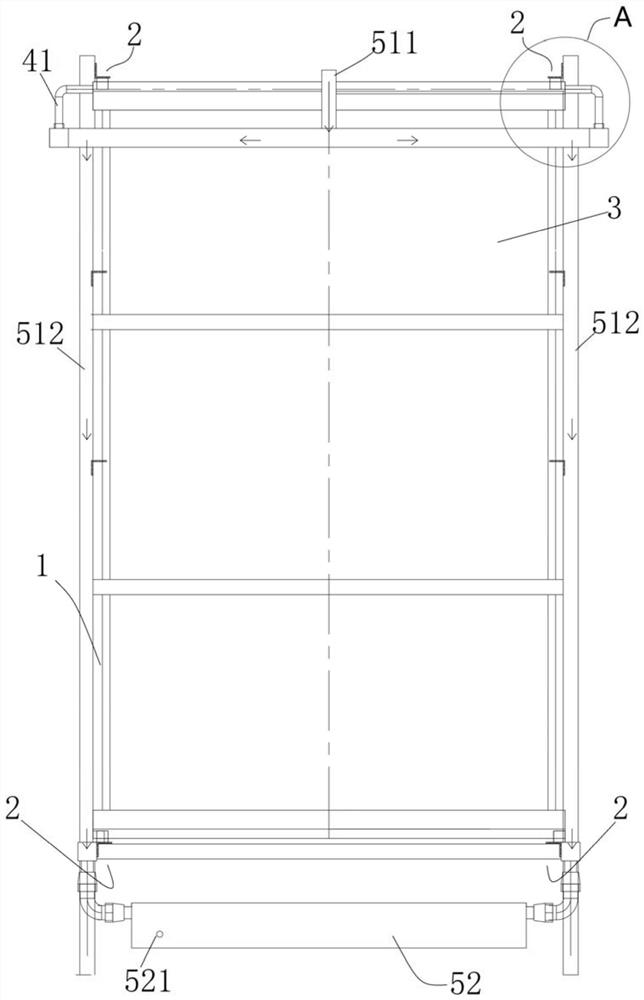

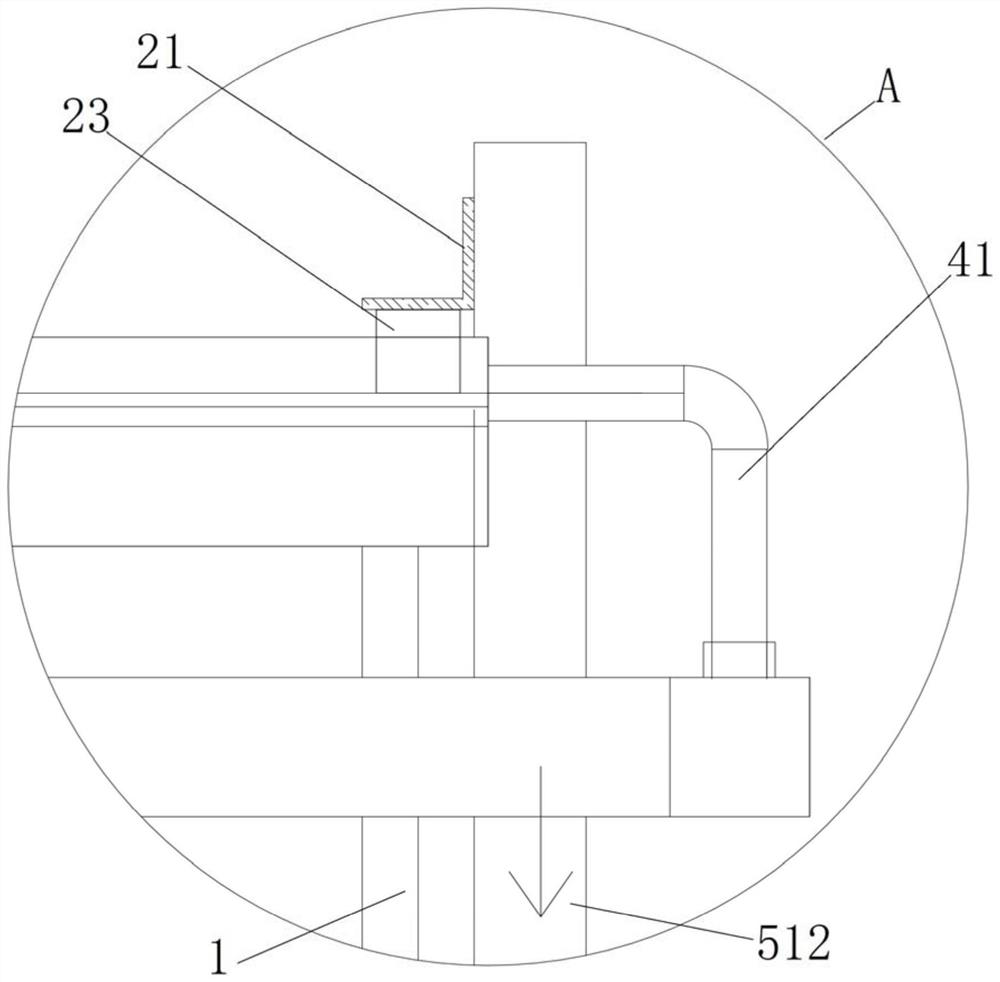

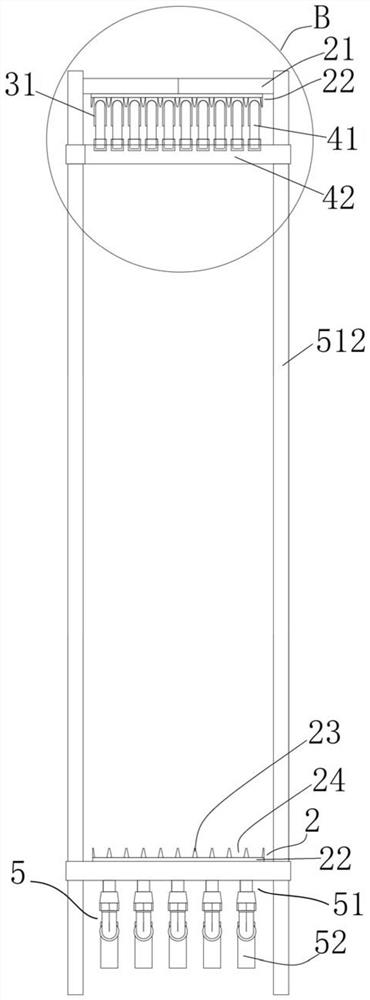

[0058] see figure 1 , remove the limit structure 2 on the frame assembly 1, and remove the water collection pipeline 4 connected with the membrane group 3, so that one end of the several diaphragms 31 constituting the membrane group 3 is self-limiting installation groove 24 of the limit structure 2 To disengage from the inside, the diaphragm 31 is pulled out from the frame assembly 1. After the diaphragm 31 is cleaned, the diaphragm 31 is inserted back to its original position and the dismantled limiting structure 2 is put back in its original position.

[0059] Compared with the existing MBR membrane stacker, which needs to be hoisted as a whole or disassembled in the lower tank when washing the membrane off-line in the integrated membrane box, the MB...

Embodiment 3

[0062] The embodiments of the present application provide a water treatment device. The water treatment device includes a biological reaction tank and an MBR membrane packager installed in the biological reaction tank, and the MBR membrane packager is the easily disassembled MBR membrane packager provided in the first embodiment. The biological reaction tank contains sewage to be treated, and the detachable MBR membrane unit filters the sewage to be treated through the membrane unit 3 on it to obtain clean water, and the filtered clean water is output from the water collection pipeline 4 of the detachable MBR membrane unit. The detachable MBR membrane unit realizes the scouring of the sludge on the membrane unit 3 through the aeration device 5 on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com