Desulfurization wastewater treatment system, and desulfurization wastewater treatment method

A desulfurization wastewater and treatment system technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of ineffective rapid cooling and high flue gas temperature, and avoid flue gas temperature Excessively high, save water resources, reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description is only for disclosing the present invention to enable those skilled in the art to practice the present invention. The preferred embodiments described below are only examples, and those skilled in the art can conceive of other obvious modifications. The basic principles of the invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and others without departing from the spirit and scope of the invention.

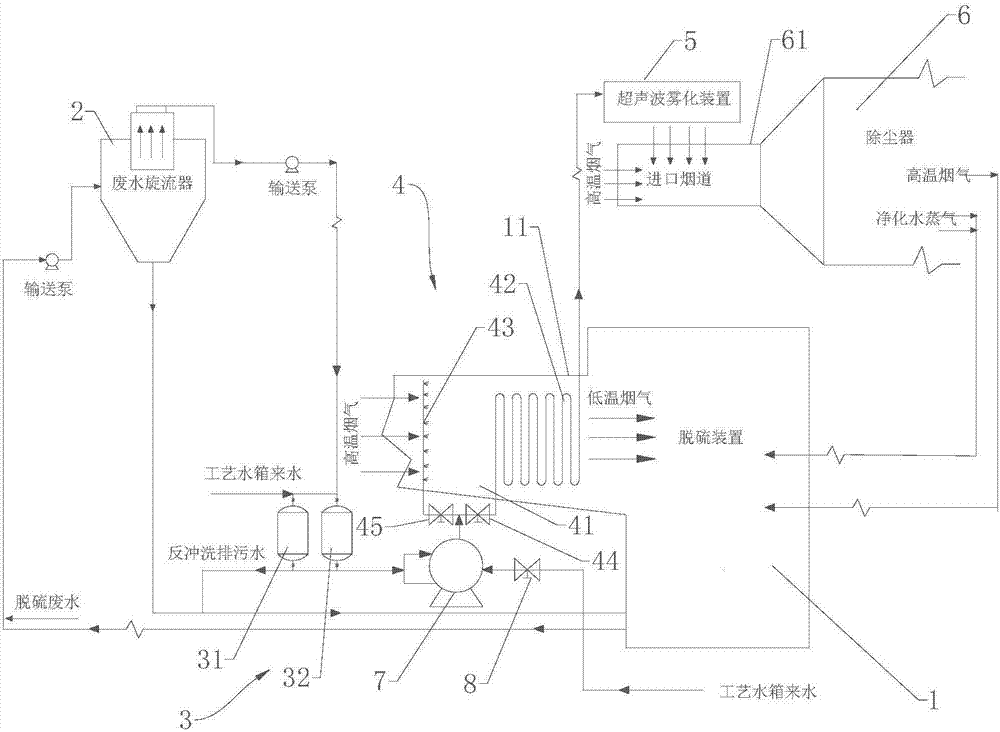

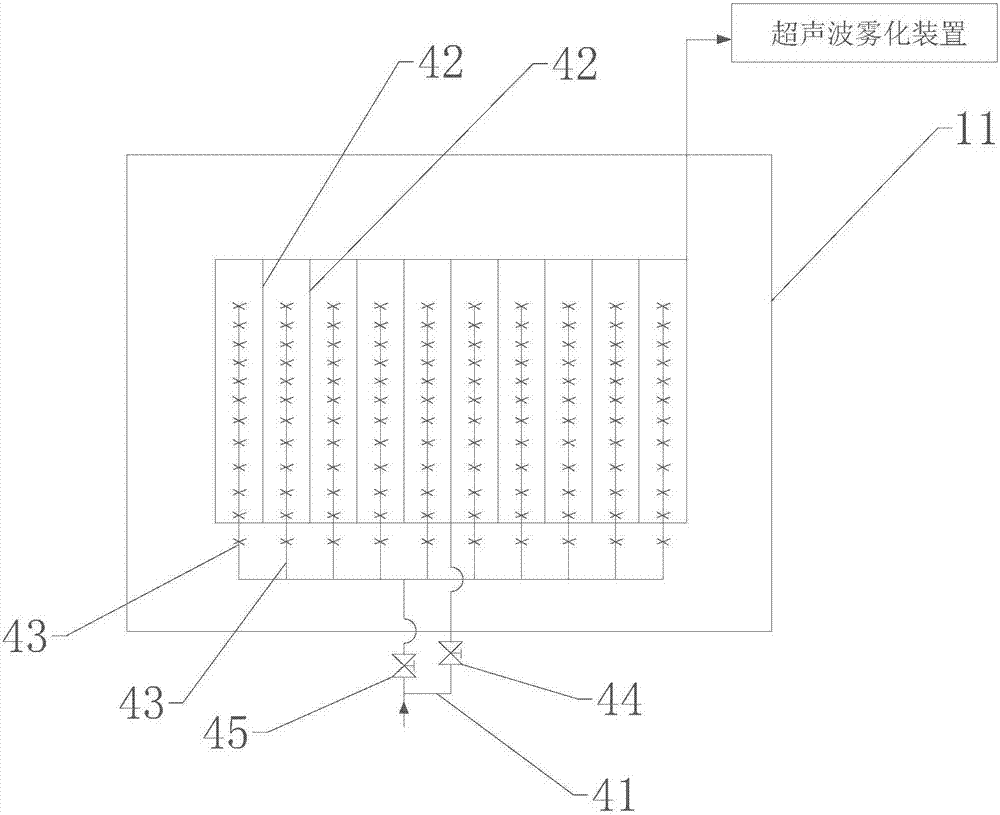

[0036] Such as figure 1 As shown, the present invention provides a desulfurization wastewater treatment system, the desulfurization wastewater treatment system includes a desulfurization device 1, a wastewater cyclone 2, a sand filter system 3, a flue heat exchanger 4, an ultrasonic atomization device 5, a dust removal Device 6. The waste water cyclone 2 is connected to the desulfurization device 1, and the waste water cyclone 2 performs solid-liquid separation on the desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com