Continuous unpowered dosing and mixing device

A mixing device and power technology, applied in the direction of mixers, feeding devices, mixers with rotating stirring devices, etc., can solve problems such as inaccurate measurement of measuring instruments, non-linear output, and inability to solve problems well. Achieve the effects of improving mixing effect, maintaining vacuum environment and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

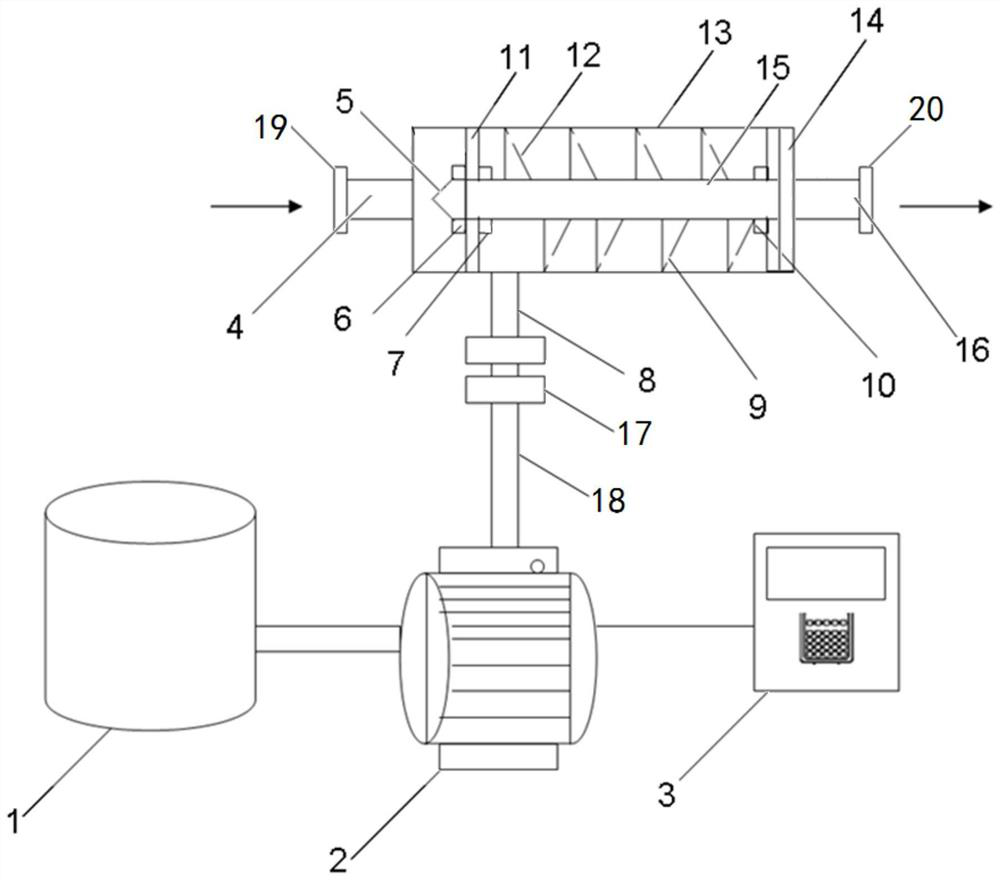

[0027] A continuous unpowered dosing mixing device, such as figure 1 , including the frequency conversion dosing module, the treated water inlet pipe 4, the impeller 6, the first limiter 7, the drug inlet pipe 8, the second limiter 10, the first fixed bracket 11, the mixed fluid pipeline 13, the second fixed bracket 14. The stirring shaft 15 and the mixing water outlet pipe 16, one end of the mixing fluid pipe 13 is communicated with the treated water inlet pipe 4, the other end is communicated with the mixing water outlet pipe 16, the side wall is communicated with the medicine inlet pipe 8, and the frequency conversion dosing module is connected with the medicine inlet pipe 8 is connected, the first fixing bracket 11 and the second fixing bracket 14 are located inside the mixed fluid pipeline 13, and are respectively close to both ends of the mixed fluid pipeline 13, and the stirring shaft 15 is movably arranged between the first fixing bracket 11 and the second fixing bracke...

Embodiment 2

[0036] In this embodiment, as figure 1 , the spiral blade 12 is provided with a number of gaps 9. When the mixed liquid flows through the gaps 9, a surge area is generated, which disrupts the flow direction of the mixed liquid, makes the liquid medicine and the treated water fully contact, achieves the purpose of mixing again, and improves the mixing Effect.

[0037] Others are the same as in Example 1.

[0038] Example 1 and Example 2 propose a continuous non-power dosing and mixing device, which integrates the dosing process and the mixing process, does not affect the water outlet speed and flow, ensures the mixing effect, does not need to add additional power, and is small in size. , the operating cost is greatly reduced, and it is convenient to seal the stirring cavity in the mixed fluid pipeline 13, maintain a vacuum environment, and have good safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com