Coating processing technology for plastic part of electric vehicle

A processing technology and technology of plastic parts, applied in the field of plastic parts processing, can solve problems such as uneven coating spraying and affecting the spraying effect of plastic parts of masks, and achieve the effect of uniform coating mixing and enhanced uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

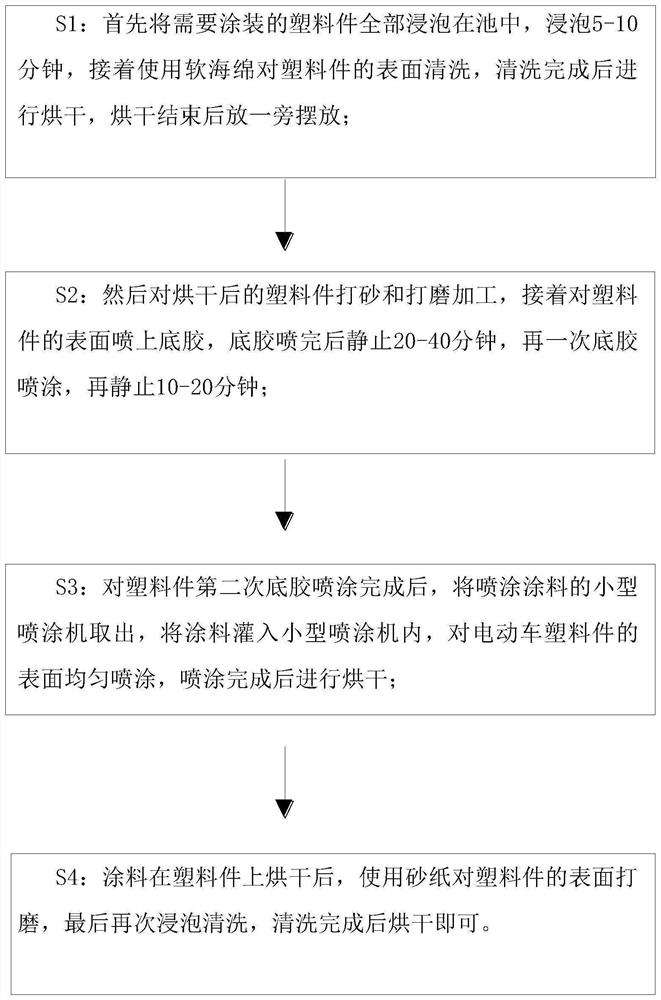

[0031] see Figure 1-5 As shown, a coating process for electric vehicle plastic parts, the coating steps are as follows;

[0032] S1: First, soak all the plastic parts to be painted in the pool for 5-10 minutes, then use a soft sponge to clean the surface of the plastic parts, dry them after cleaning, and put them aside after drying;

[0033] S2: Then sand and polish the plastic parts after drying, then spray the surface of the plastic parts with primer, after the primer is sprayed, stand for 20-40 minutes, spray the primer again, and then stand still for 10-20 minutes ;

[0034] S3: After the second primer spraying on the plastic parts is completed, take out the small sprayer that sprays the paint, pour the paint into the small sprayer, spray evenly on the surface of the plastic parts of the electric vehicle, and dry after spraying;

[0035] S4: After the paint is dried on the plastic parts, use sandpaper to polish the surface of the plastic parts, and finally soak and clea...

Embodiment 2

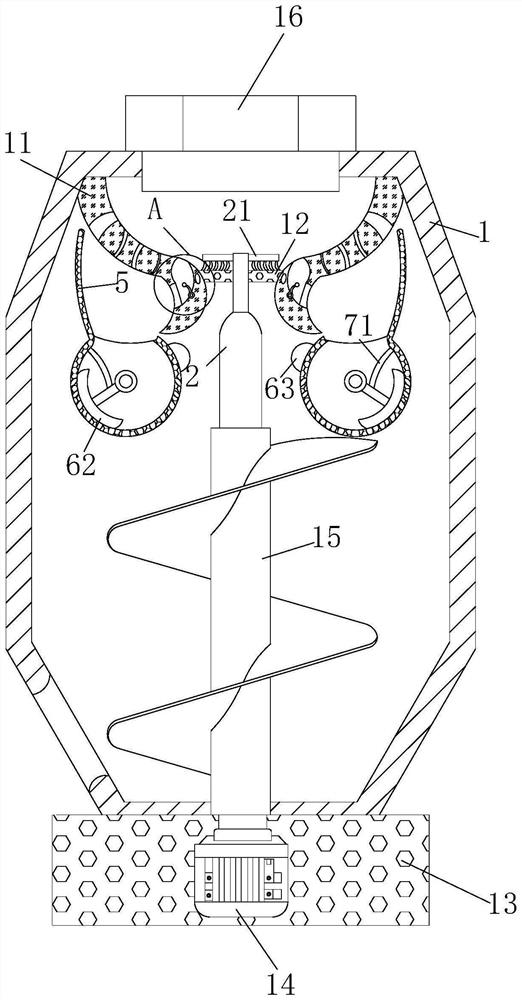

[0044] see Image 6 As shown in the comparative example 1, as another embodiment of the present invention, the bottom end of the sealing cover 16 is fixed with a sealing gasket 8; The holes at the ends correspond to each other; when working, in order to avoid excessive paint overflowing from the end of the paint mixing tank 1 when the stirring blade 15 is stirred, the sealing gasket 8 is fixed at the bottom end of the sealing cover 16 to achieve a sealing effect to avoid the paint It overflows during stirring, and at the same time protects the end of the paint stirring tank 1.

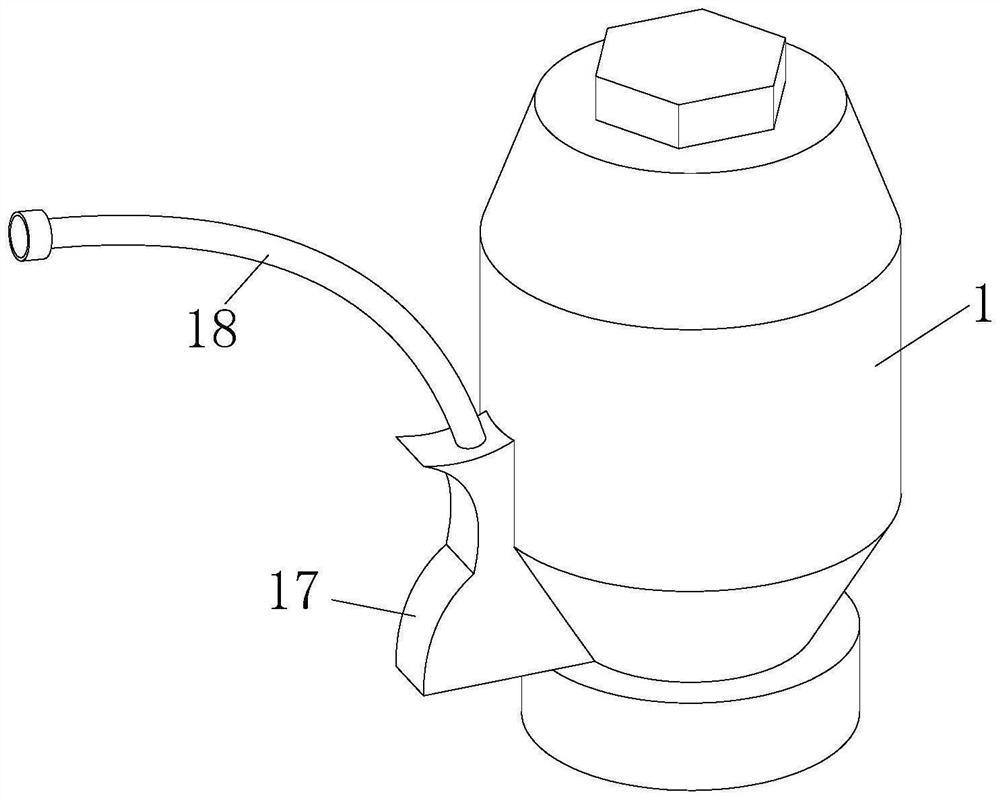

[0045] Working principle, the staff unscrewed the sealing cover 16, poured the paint into the paint mixing tank 1 and poured the paint on the end of the filter screen plate 12 for filtering, and filtered the solidified paint and impurities at the end of the filter screen plate 12, When too much paint is poured into the side wall of the deflector block 11, it overflows and falls from the multiple sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com