Metal rod welding device for fitness equipment production

A welding device and fitness equipment technology, which is applied in welding equipment, metal processing equipment, laser welding equipment, etc., can solve the problems of uneven welding scars and not necessarily grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

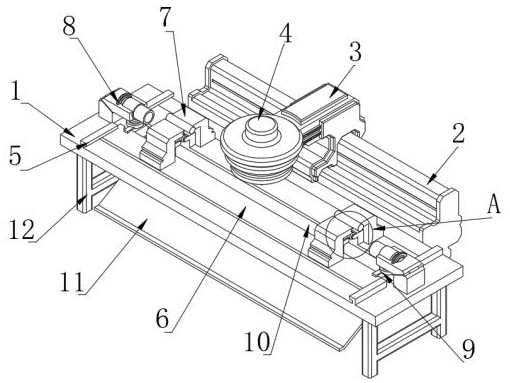

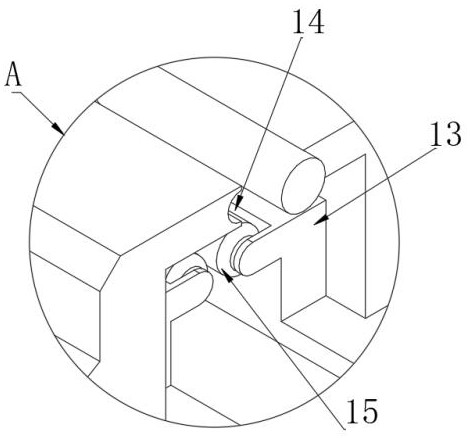

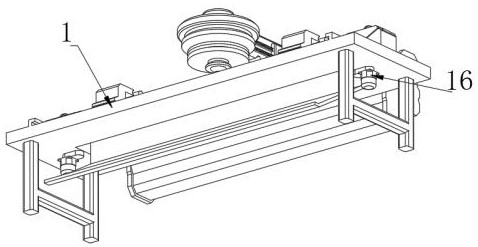

[0036] like Figures 1 to 11 As shown, an embodiment of the present invention provides a metal rod welding device for fitness equipment production, including a workbench 1, an electric slide rail 2 is fixedly installed at the rear end of the workbench 1, and a laser is slidably installed on the electric slide rail 2 The welding machine installation table 3, the front end of the laser welding machine installation table 3 is fixedly installed with the laser welding machine 4, the upper end surface of the work table 1 is provided with a feeding chute 10, and the upper end surface of the work table 1 is located in the feeding chute 10. Four mounting plate limit chutes 5 are integrally and fixedly installed at both ends of the two sides, and a mounting plate 6 is slidably installed in each two sets of the mounting plate limit chutes 5, and two of the mounting plates 6. Two mounting plate synchronizing assemblies 9 are fixedly installed at both ends respectively, and two barbell bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com