Nine-shaft series connection type macro-micro combined assembly robot system

A robot system and robot technology, applied in the direction of manipulators, program-controlled manipulators, metal processing equipment, etc., can solve the problems of micro-assembly robots lacking versatility and not being able to meet high-precision micro-device products, etc. It is easy to choose benchmarks and has strong versatility , the effect of fast movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

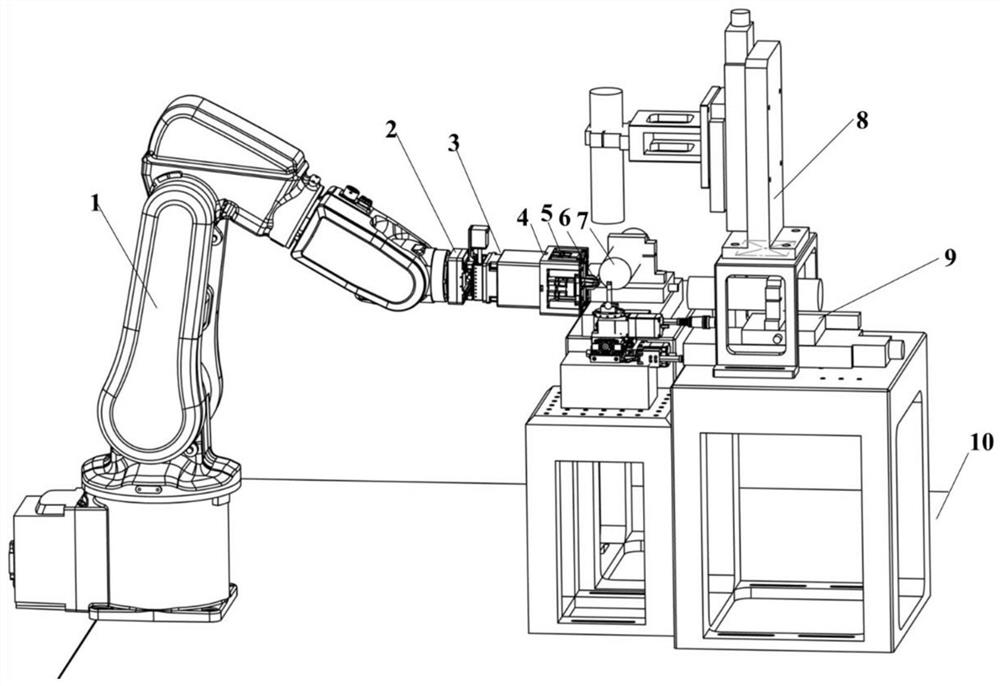

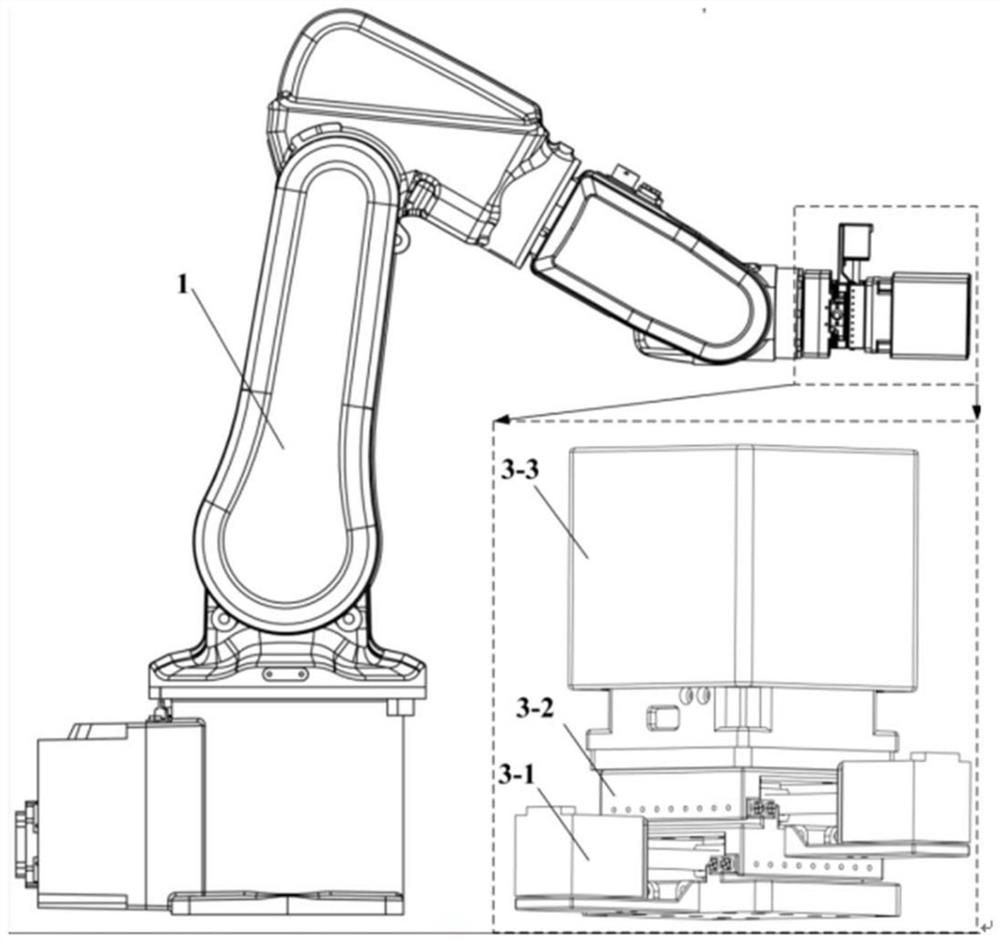

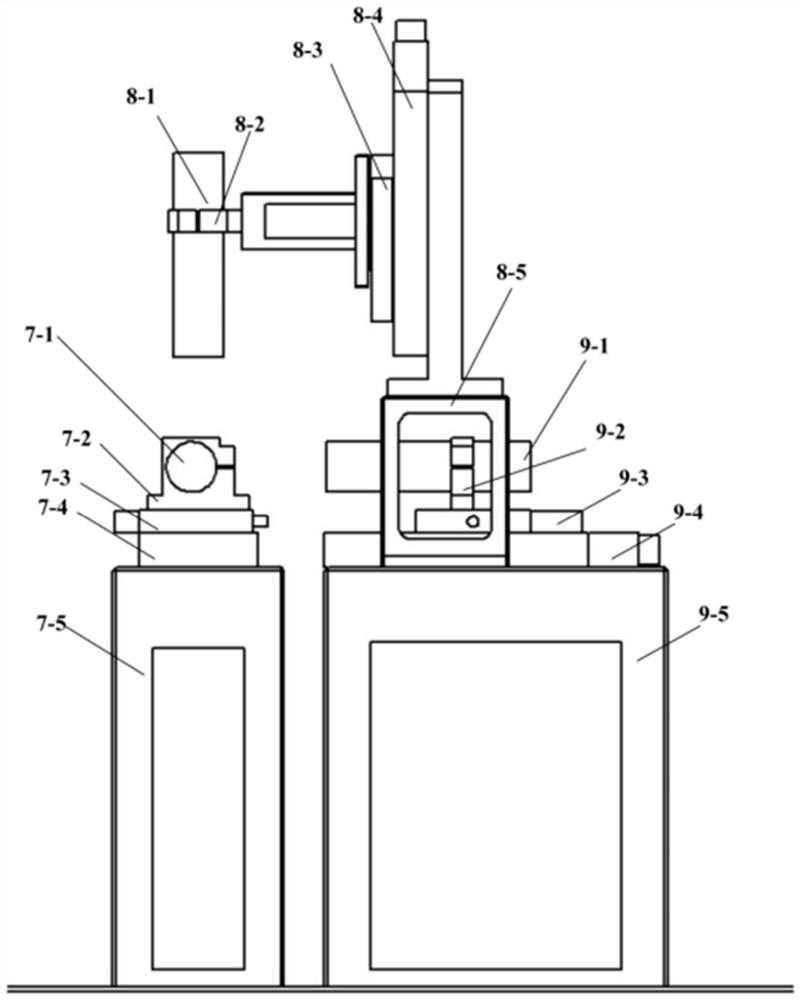

[0026] like Figure 1 to Figure 4 , a nine-axis serial macro-micro combined assembly robot system, the macro-micro combined high-precision assembly robot system includes a six-freedom macro-motion robot 1, a three-degree-of-freedom micro-motion robot 3, an end manipulator 5, a force perception module 6, a three-dimensional Microscopic Vision Module. Among them, the macro-micro combined high-precision assembly robot body adopts a tandem structure, and the six-free macro robot 1 is installed on the vibration isolation table 10 by bolt connection, and different types of end micro-manipulators can be replaced according to different operation objects.

[0027] The macro-micro combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com