Modular composite material reinforcing rib structure and rib plate

A composite material board and composite material technology, which is applied in the field of modular composite material rib structure and rib board, can solve the problems of large mold cost, consumption, and difficulty in unifying the quality control of different parts, and achieve easy maintenance and replacement. The effect of strong performance and improvement of product quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

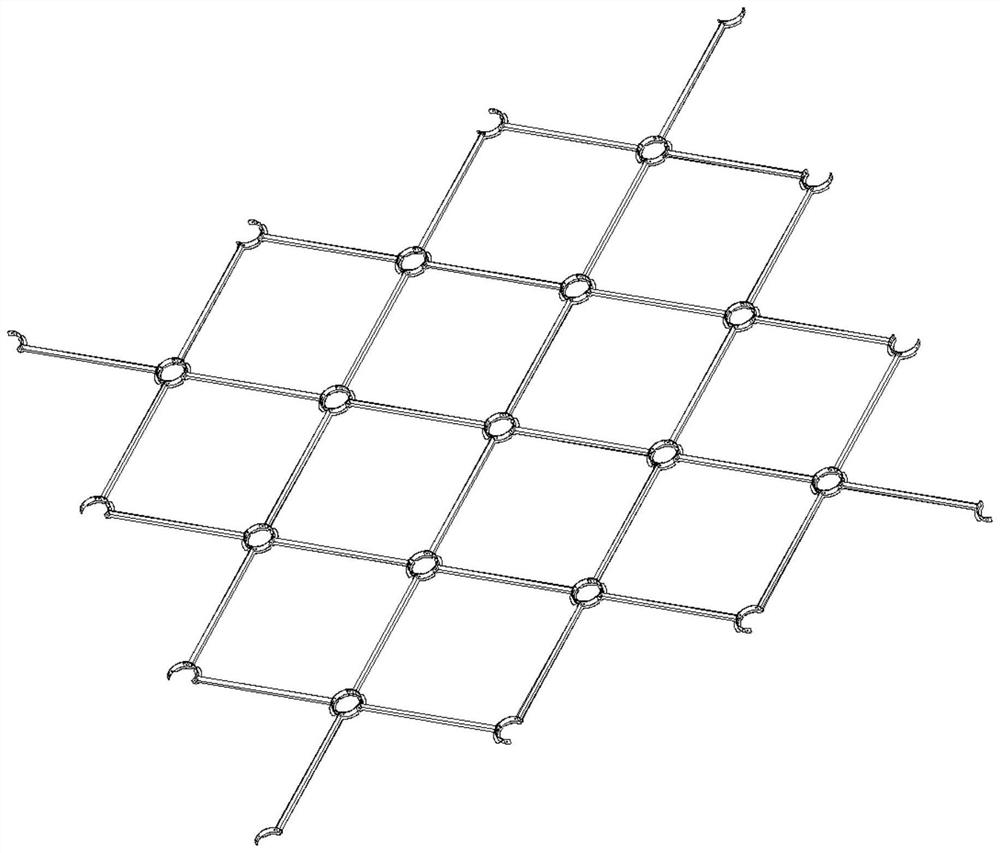

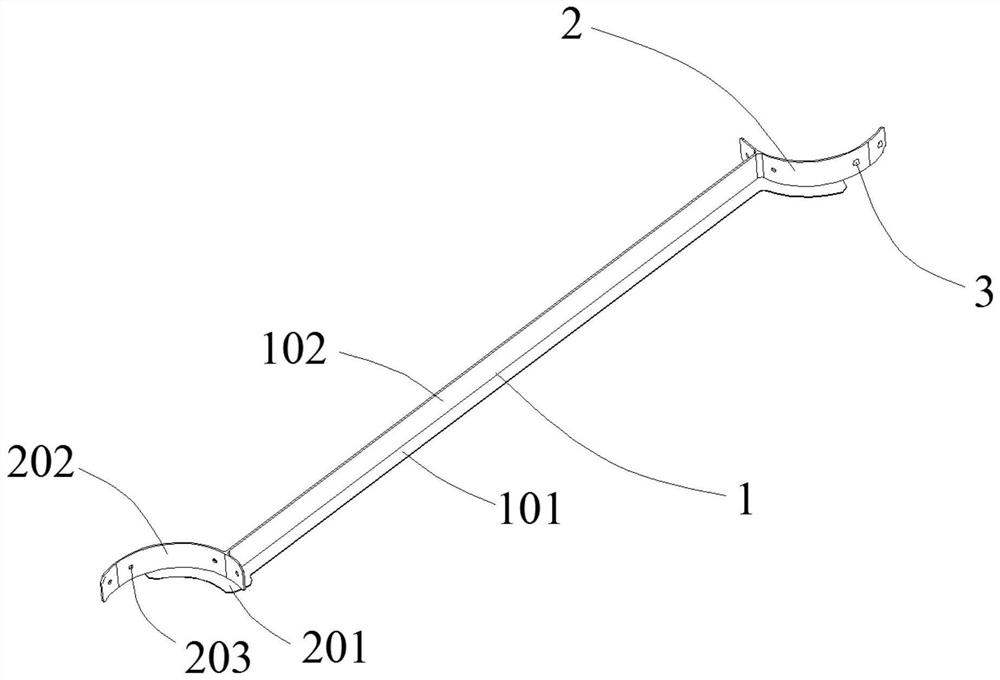

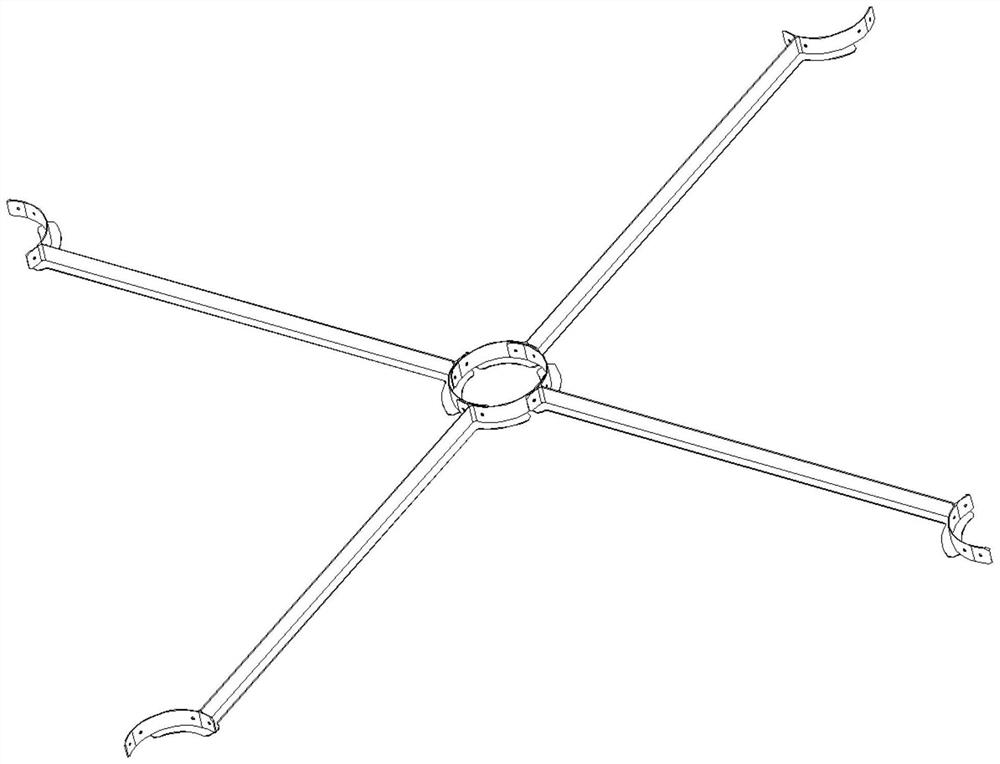

[0046] refer to Figure 1 to Figure 4 , the present embodiment discloses a modular composite material reinforcing rib structure, which is formed by splicing a plurality of reinforcing rib modules, and each reinforcing rib module includes a reinforcing rib main body 1 and two connecting heads 2 connected to the reinforcing rib main body 1 .

[0047] The reinforcing rib body 1 has a linear shape, including a main body flange 101 and a main body beam rib 102. The main body flange 101 and the main body beam rib 102 are vertically arranged. In this embodiment, the cross section of the reinforcing rib body 1 is T-shaped structure, that is to say, each reinforcing rib main body 1 includes a main body flange 101 and a main body beam rib 102. The main body beam rib 102 is mainly used for bearing and improving the overall rigidity of the structure. The main body flange 101 is mainly used for For the connection function, the reinforcing rib main body 1 is connected and fixed with the ex...

Embodiment 2

[0053] The rest of this embodiment is the same as that of Embodiment 1, the difference is that refer to Image 6 , in this embodiment, each connector 2 is connected with the connector 2 on 2 different reinforcing rib modules to form a circular connecting portion, that is, the connecting portion is formed by connecting 3 different reinforcing rib modules. In the example, when three different reinforcing rib modules are connected, the reinforcing rib main bodies 1 on each reinforcing rib module are arranged at 120° to each other, such as: Figure 7 As shown, the reinforcing rib formed between such a plurality of reinforcing rib modules forms a grid-like reinforcing rib with a hexagonal structure.

Embodiment 3

[0055] refer to Figure 8 and Figure 9 , the rest of this embodiment is the same as in Embodiment 1, the difference is that in this embodiment, each connector 2 is connected to the connector 2 on 5 different reinforcing rib modules to form a circular That is, the connecting portion is formed by connecting 6 different reinforcing rib modules. In this embodiment, when 6 different reinforcing rib modules are connected, the reinforcing rib main bodies 1 on each reinforcing rib module are arranged at 60° to each other, so that a plurality of reinforcing ribs The reinforcing ribs formed between the modules form a grid-like reinforcing rib with a triangular structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com