Automatic packaging equipment for optical filter switcher

A technology of packaging equipment and switching devices, which is applied in the direction of packaging automatic control, packaging, packaging machines, etc., can solve the problems of inability to warn the staff and low work efficiency, and achieve the effects of reducing operation troubles, improving work efficiency, and facilitating packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

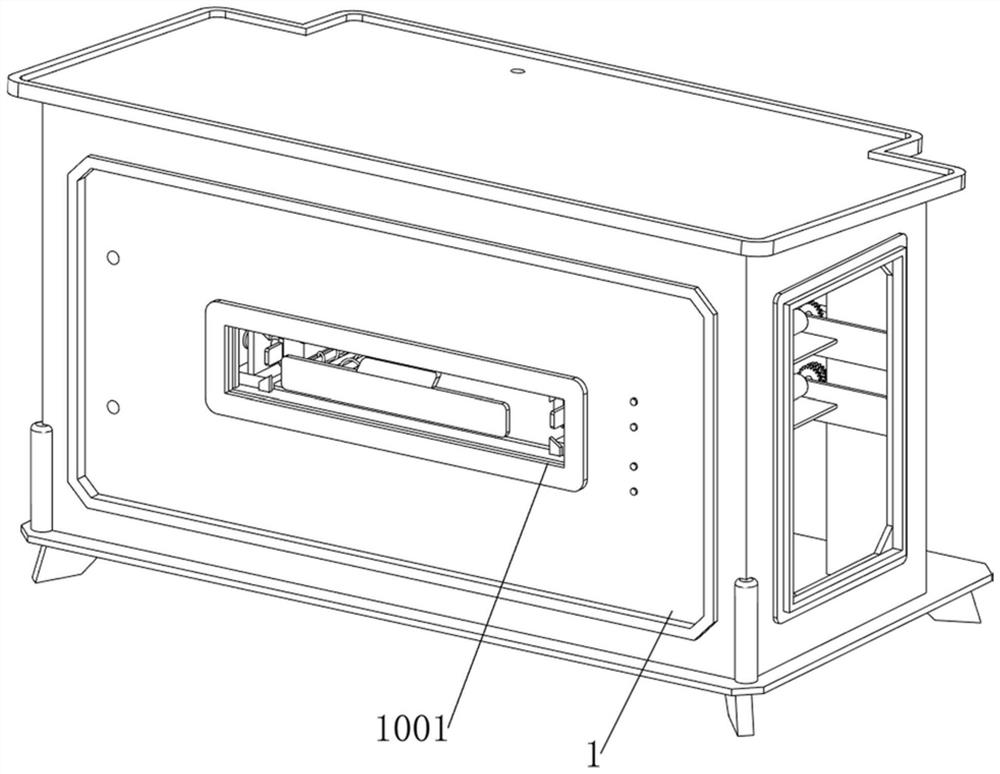

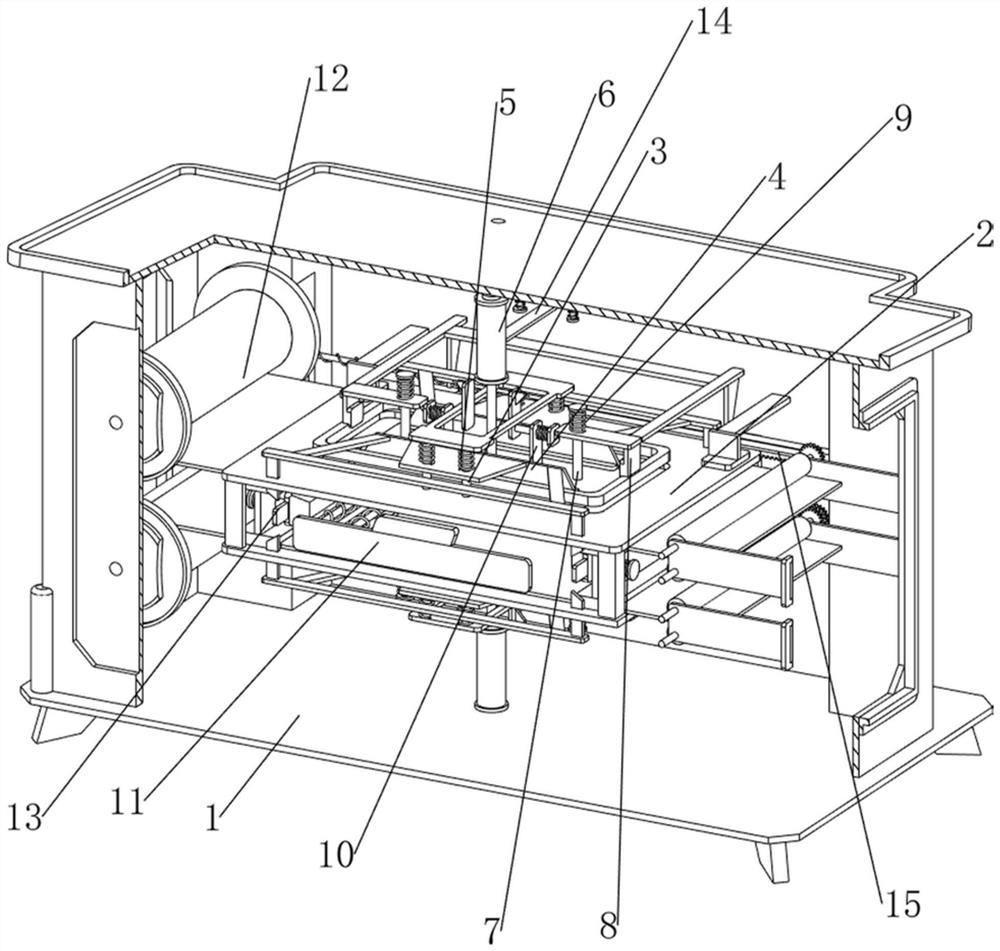

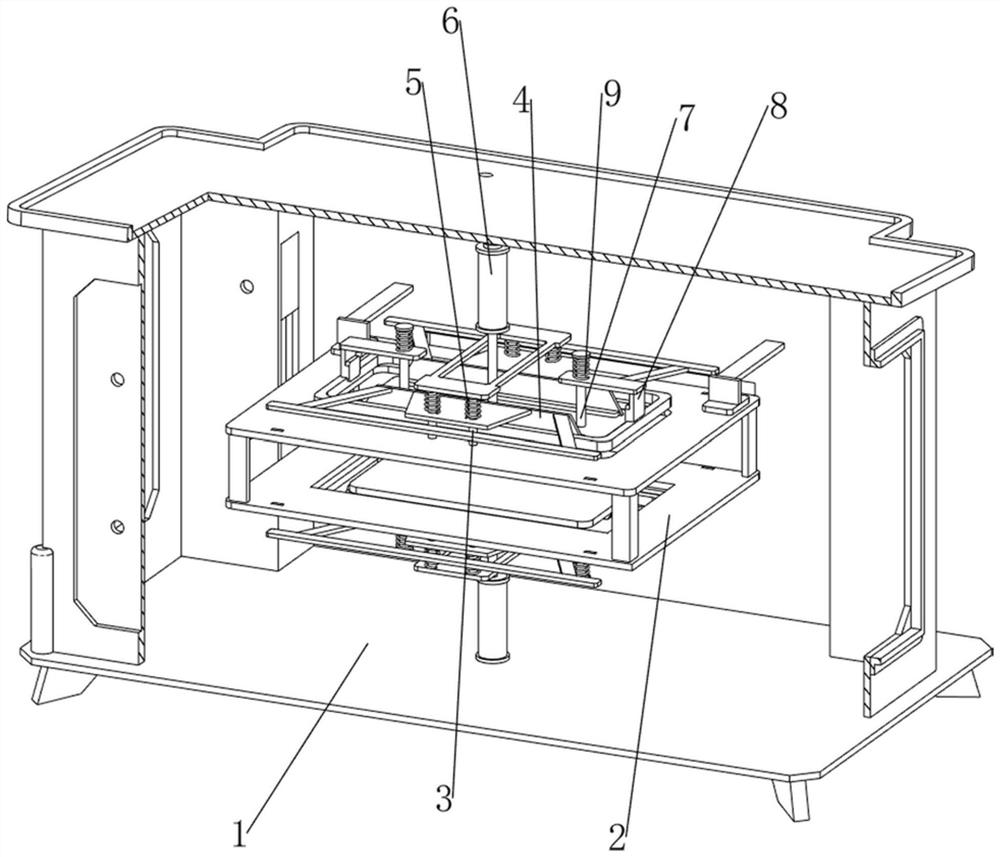

[0083] A filter switcher automatic packaging equipment, see figure 1 , figure 2 , image 3 and Figure 4 , including the outer connection frame 1, the feed port 1001, the opening 11001, the square port 11002, the inner connection frame 2, the through hole 11003, the connection frame 3, the sliding pressure plate 4, the first spring 5, the cylinder 6, the button 61, the support rod 7. The heater 8, the second spring 9, the release mechanism 10 and the positioning driving mechanism 11. The outer connecting frame 1 has a feeding port 1001 in the middle of the front side, and an opening 11001 is opened on the left rear side of the top of the outer connecting frame 1. The outer connecting frame 1. There is a square opening 11002 in the middle of the rear side, an inner connecting frame 2 is welded in the middle of the outer connecting frame 1, a through hole 11003 is opened on the rear side of the left part of the inner connecting frame 2, and a connecting frame 3 is welded on t...

Embodiment 2

[0088] On the basis of Example 1, see figure 2 and Figure 11 It also includes a film-adding mechanism 12, which is convenient for placing the film cloth. The film-adding mechanism 12 includes a winding wheel 1201, a packaging film 1202, a fixing plate 1203 and a rotating drum 1204. The left side of the outer connecting frame 1 is rotated and installed. There are two detachable winding wheels 1201, both of which are covered with a packaging film 1202, four fixing plates 1203 are welded on the right side of the outer connecting frame 1, and the left part of the two fixing plates 1203 on the upper side is There are two rotating rollers 1204 connected in rotation between the left part of the two fixed plates 1203 on the lower side and the lower side. The rotating rollers 1204 are used to drive the packaging film 1202 to move, and one end of the upper packaging film 1202 passes through the inner connecting frame. 2 is located between the two rotating drums 1204 on the upper side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com