Polar region pipeline electric heat tracing system

A pipeline electric and axis technology, applied in the field of polar pipeline electric heat tracing system, can solve the problems of affecting construction progress, complicated construction, low efficiency, etc., and achieve the effects of improving construction efficiency, reducing manual winding, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

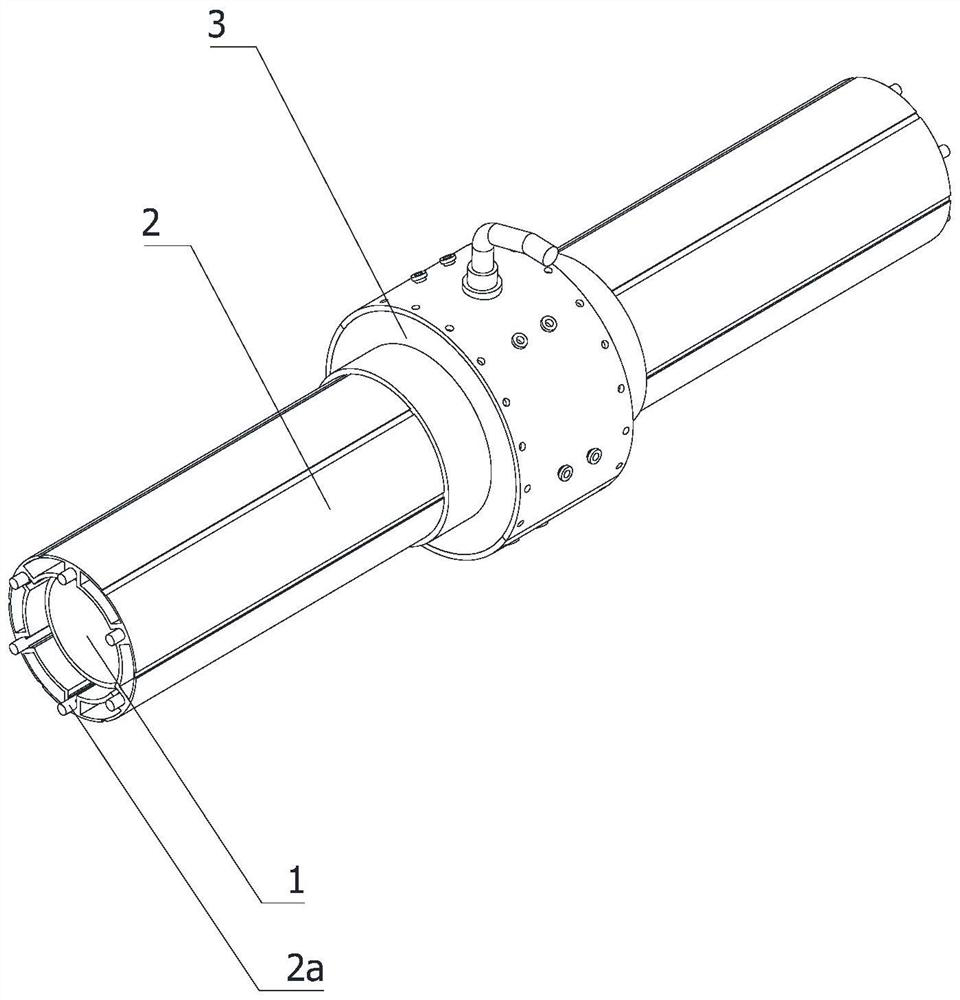

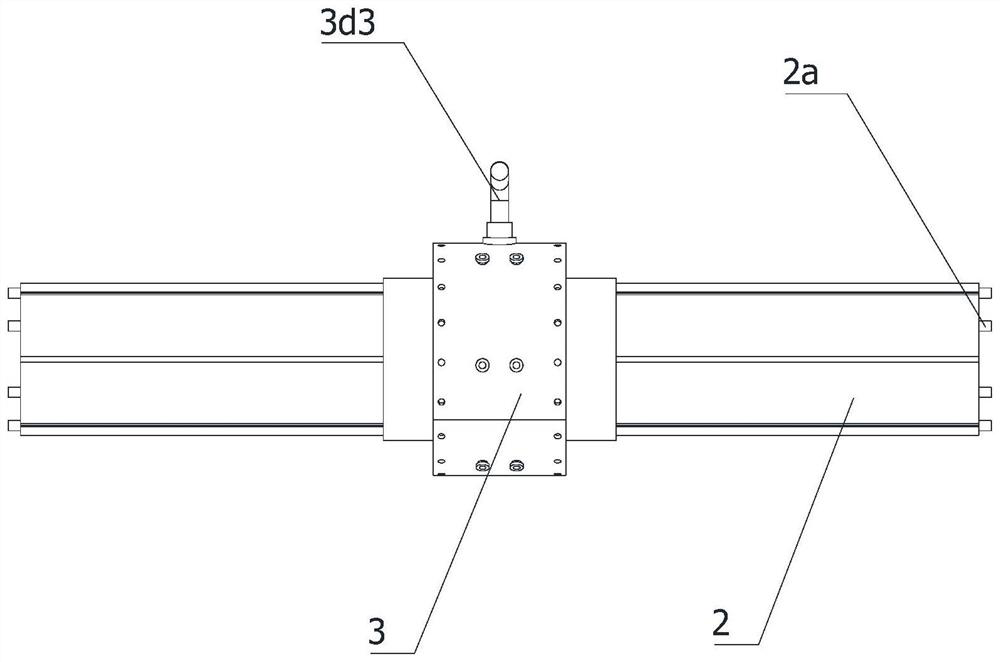

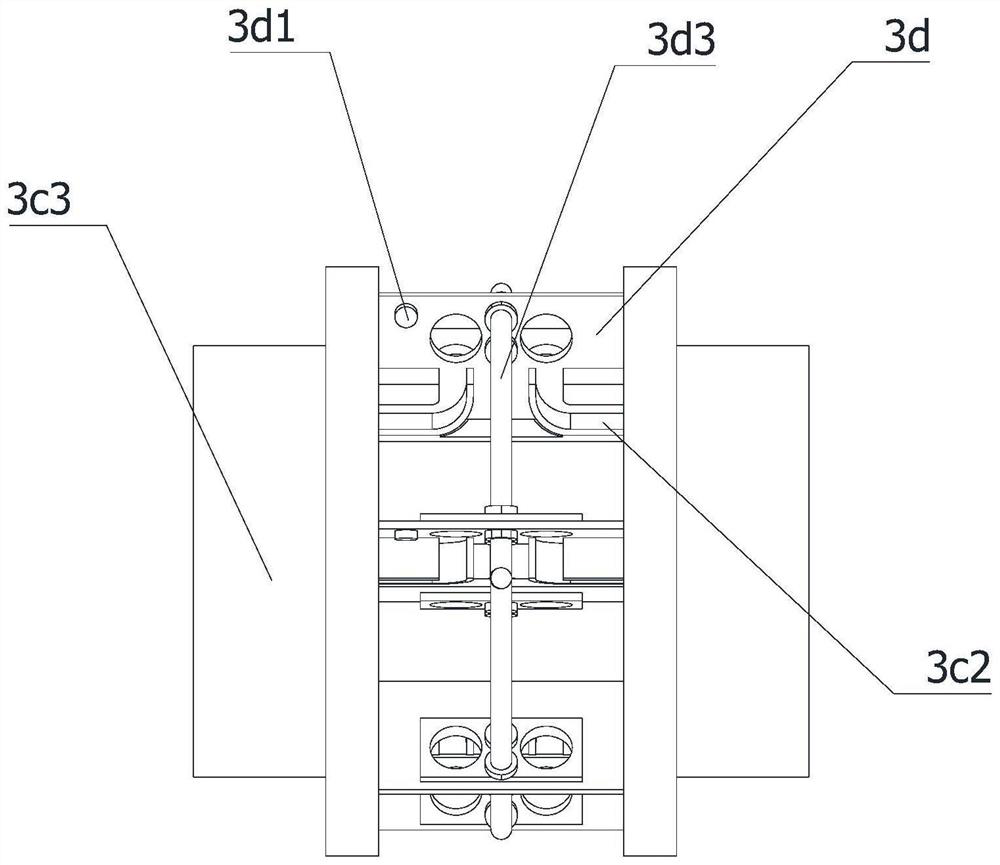

[0043] like Figure 1-12 As shown, this application provides:

[0044] An electric heat tracing system for a polar pipeline, comprising a transmission pipeline 1, a thermal insulation pipeline 2 sleeved on the outside of the transmission pipeline 1, and a connection mechanism 3 connecting two adjacent thermal insulation pipelines 2, and the thermal insulation pipeline 2 is provided with There are several heating cables 2a equidistantly arranged around its axis, and the connecting mechanism 3 includes a connecting head 3a, a through hole 3b, two limit plates 3c, several mounting plates 3d and several for winding the heating cable 2a. The winding assembly 3e and several positioning assemblies 3f for fixing the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com