Electrolytic etching method for displaying two-phase structure and grain boundary of duplex stainless steel

A duplex stainless steel, grain boundary technology, applied in the field of metallographic erosion, can solve the problem that the two-phase grain boundary of duplex stainless steel cannot be displayed, and achieve the effect of accurate and reliable data parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

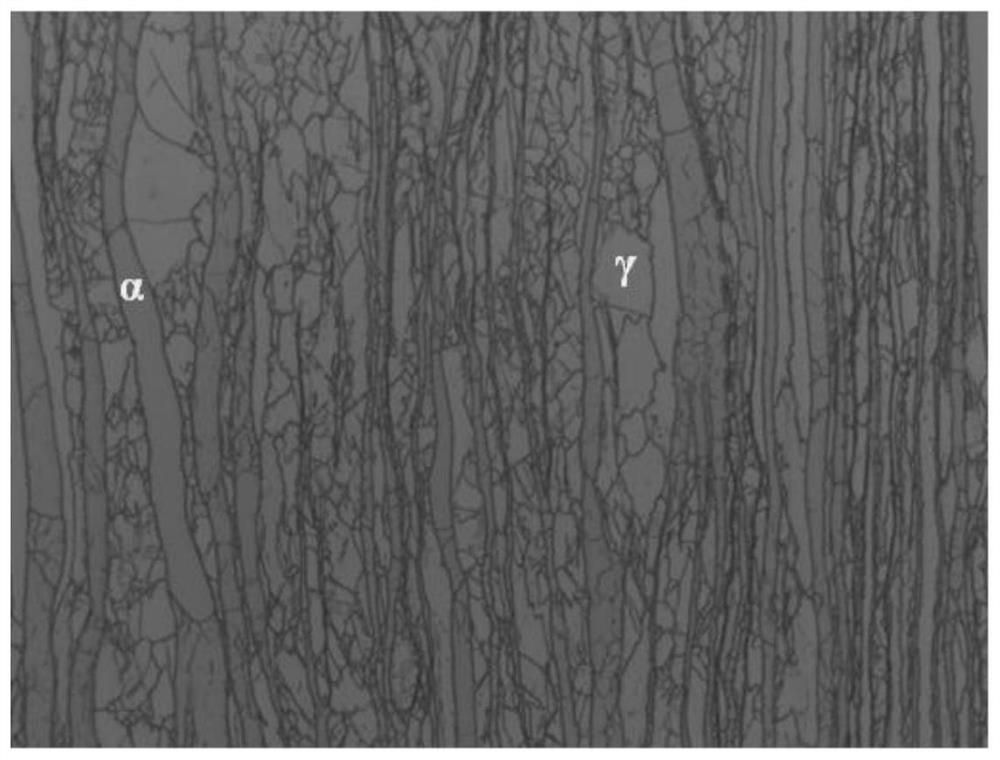

Embodiment 1

[0038] The selected material is 20Cr3Mn1Ni resource-saving duplex stainless steel hot-rolled sheet, and its composition by mass percentage is: C: 0.02%, Cr: 20%, Mn: 3%, Ni: 1%, Si: 0.35, N: 0.2% , the remainder is Fe; the metallographic microscope model is Leica DM13000H.

[0039] The specific operation steps of this embodiment are as follows:

[0040] Step 1: Prepare metallographic samples.

[0041] (1) Use a molybdenum wire cutter to cut metallographic samples from the hot-rolled sheet;

[0042] (2) Use 80#, 180#, 240#, 400#, 800#, 1000# sandpaper from coarse to fine to grind the observation surface of the metallographic sample;

[0043](3) Use a metallographic polishing machine equipped with a velvet polishing cloth to mechanically polish the observation surface of the metallographic sample until the polished surface is bright and free of scratches. The polishing agent used for mechanical polishing is 1.5 μm diamond spray polishing agent.

[0044] The second step: formu...

Embodiment 2

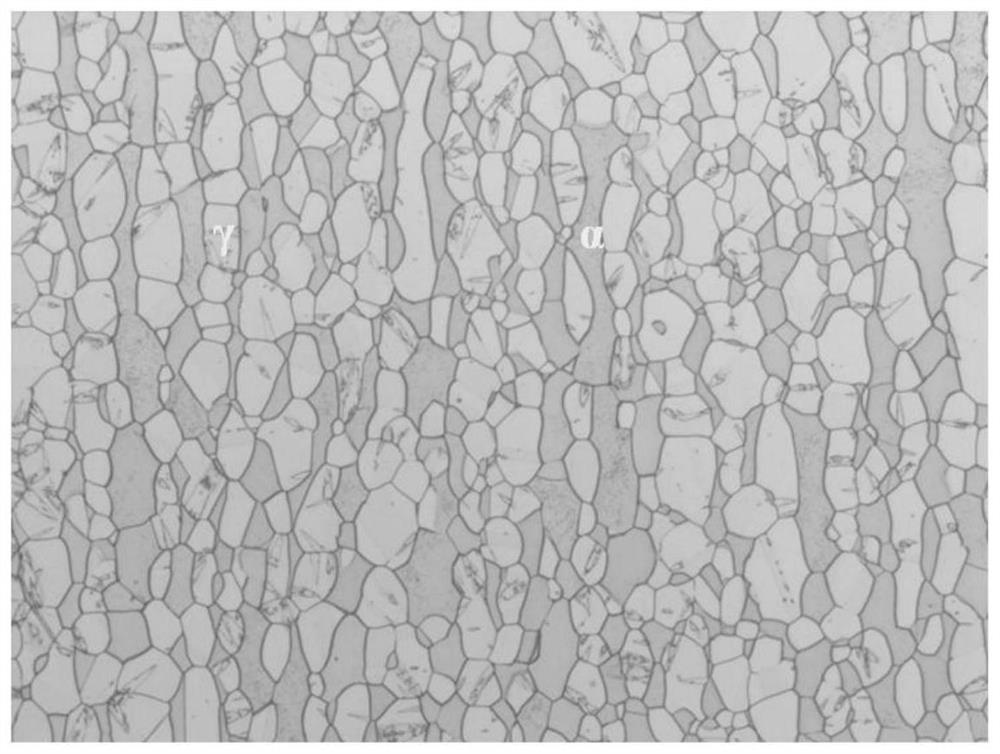

[0058] The selected material is 20Cr3Mn1Ni resource-saving duplex stainless steel plate after solution treatment, and its components are: C: 0.02%, Cr: 20%, Mn: 3%, Ni: 1%, Si: 0.35, N: 0.2%, the balance is Fe; the metallographic microscope model is Leica DM13000H.

[0059] The specific operation steps of this embodiment are as follows:

[0060] Step 1: Prepare metallographic samples.

[0061] (1) Use a molybdenum wire cutting machine to cut metallographic samples from the plate;

[0062] (2) Use 80#, 180#, 240#, 400#, 800#, 1000# sandpaper from coarse to fine to grind the observation surface of the metallographic sample;

[0063] (3) Use a metallographic polishing machine equipped with a velvet polishing cloth to mechanically polish the observation surface of the metallographic sample until the polished surface is bright and free of scratches. The polishing agent used in mechanical polishing is 1.5 μm diamond spray polishing agent.

[0064] Step 2: Configure Electrolytic ...

Embodiment 3

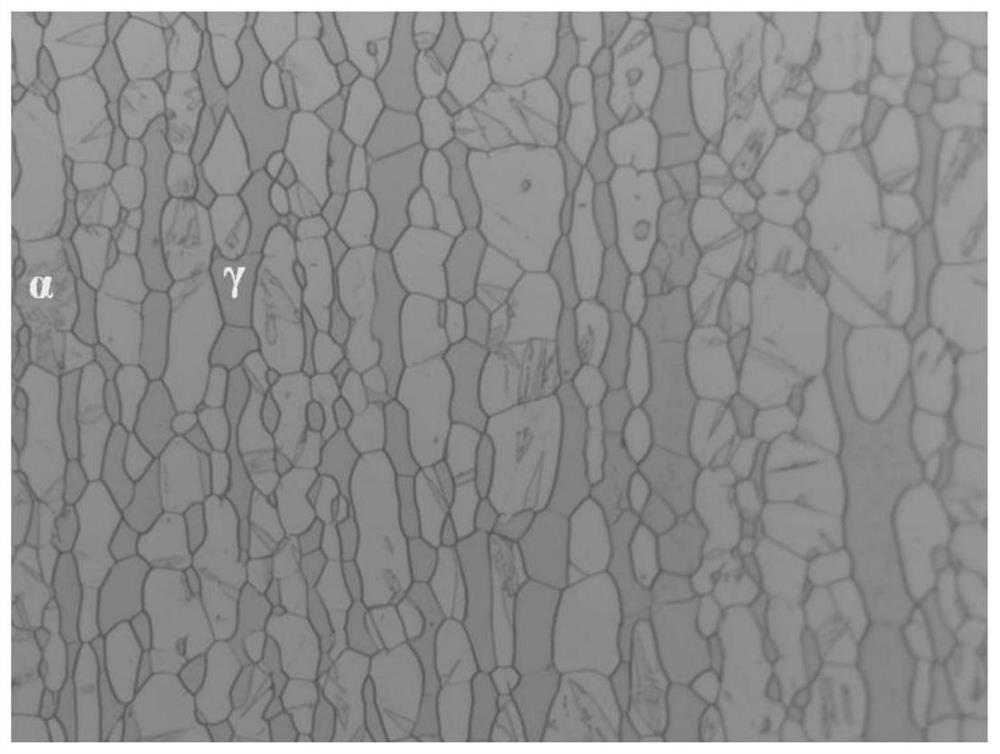

[0078] The selected material is 20Cr3Mn1Ni2Cu resource-saving duplex stainless steel plate after solution treatment, and its composition by mass percentage is: C: 0.02%, Cr: 20%, Mn: 3%, Ni: 1%, Cu: 2%, Si : 0.35, N: 0.2%, the balance is Fe; the metallographic microscope model is Leica DM13000H.

[0079] The specific operation steps of this embodiment are as follows:

[0080] Step 1: Prepare metallographic samples.

[0081] (1) Use a molybdenum wire cutting machine to cut metallographic samples from the plate;

[0082] (2) Use 80#, 180#, 240#, 400#, 800#, 1000# sandpaper from coarse to fine to grind the observation surface of the metallographic sample;

[0083] (3) Use a metallographic polishing machine equipped with a velvet polishing cloth to mechanically polish the observation surface of the metallographic sample until the polished surface is bright and free of scratches. The polishing agent used in mechanical polishing is 1.5 μm diamond spray polishing agent.

[0084] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com