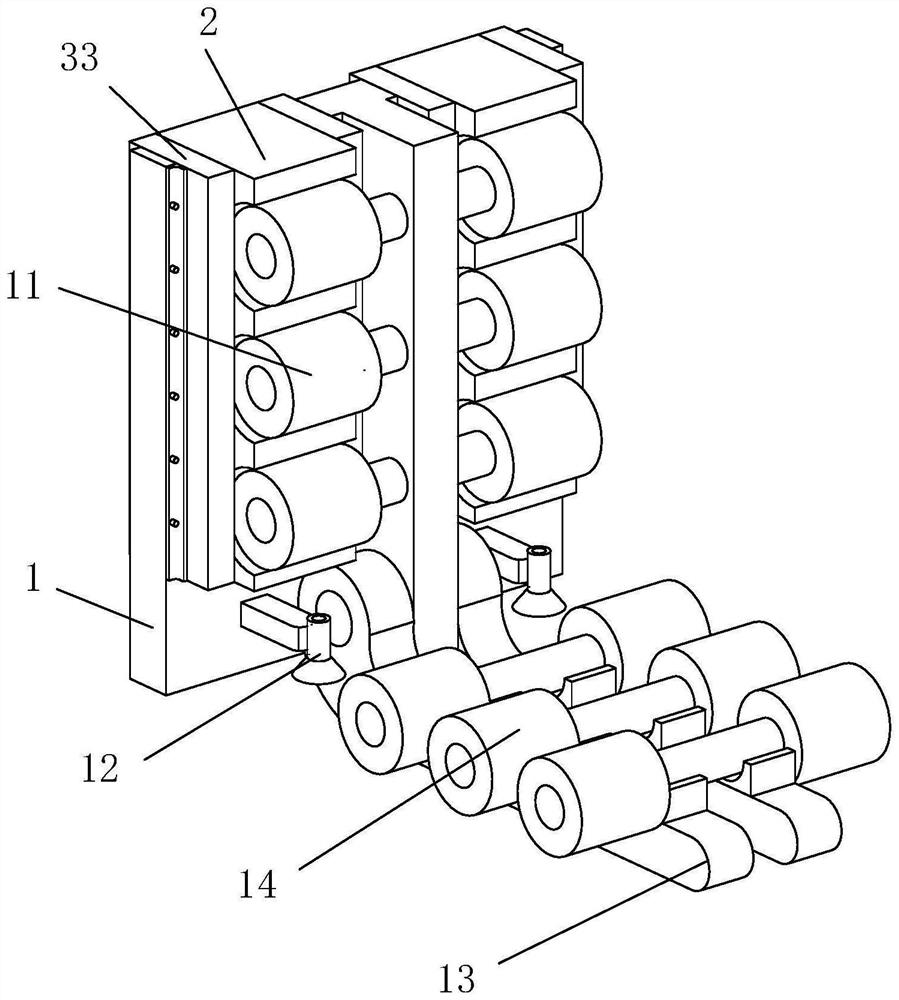

Environment-friendly rotor spinning machine

An air spinning machine, environmental protection technology, applied in the direction of spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problems of roller accumulation, yarn coarse and fine details, etc., to reduce The effect of accumulating flowers and improving the degree of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

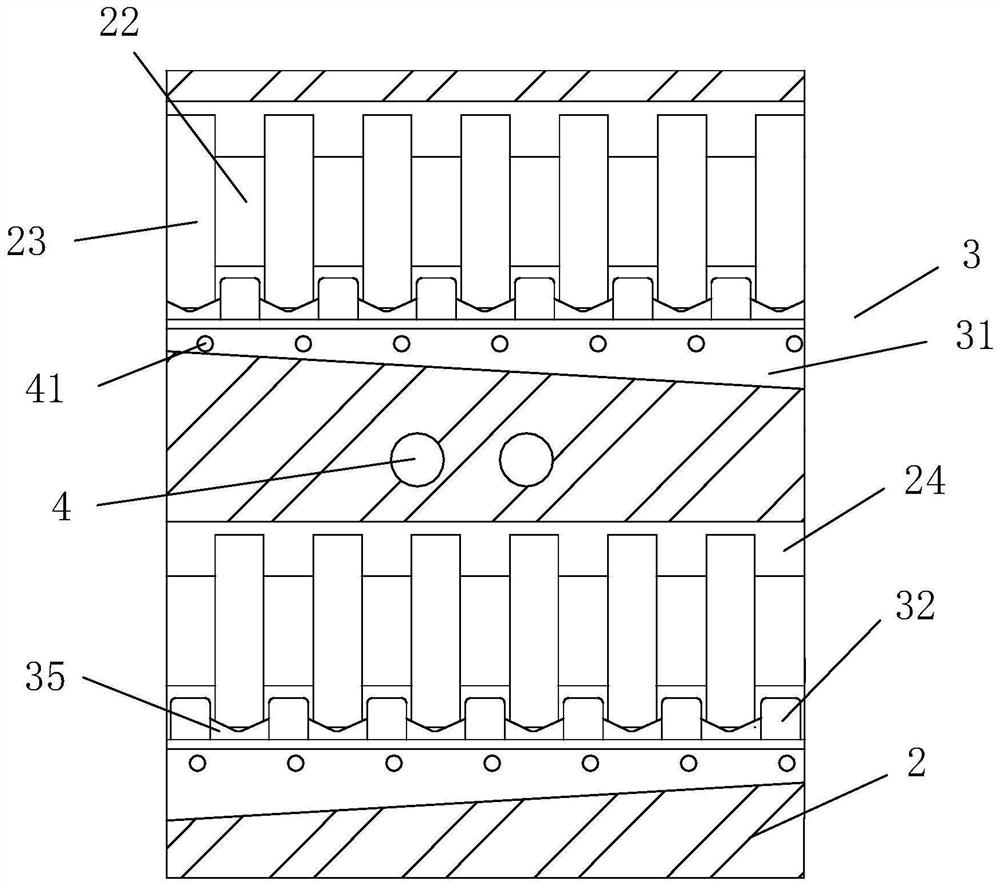

[0066] As an embodiment of the present invention, the hole diameter of the injection hole 4 at one end of the injection hole 4 close to the mounting plate 1 is larger than the hole diameter of the injection hole 4 at the end of the feed roller 11 .

[0067] During operation, the overall shape of the injection hole 4 is horn-shaped, so as to compress the gas ejected from the injection hole 4 to a certain extent, increase the kinetic energy of the injection, and then better feed the fluff in the groove on the roller 11. Cleaning is performed to improve the cleanliness of the feeding roller 11 and reduce the appearance of flower accumulation on the surface of the feeding roller 11.

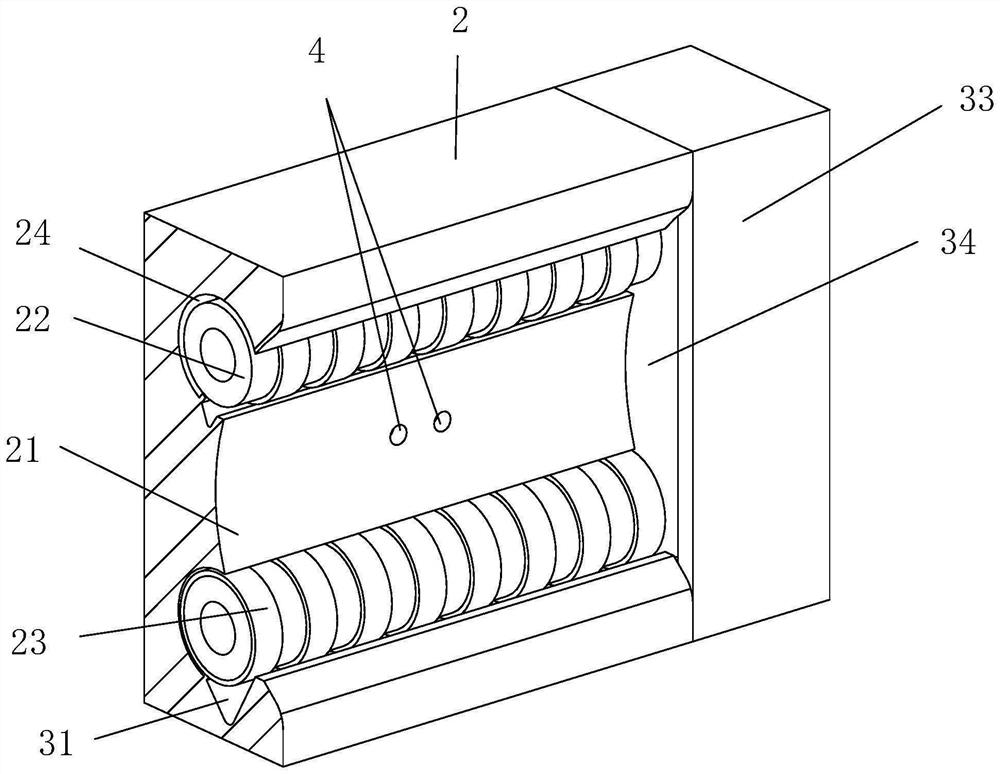

[0068] As an embodiment of the present invention, such as image 3 As shown, evenly distributed inclined holes 41 are formed on the groove wall of the inclined groove 31 , and the holes of the inclined holes 41 face the collecting cylinder 33 .

[0069] During operation, the oblique hole 41 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com