Forming knitting machine for manufacturing seamless down jacket fabric

A technology for down jacket fabrics and knitting machines, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of complicated operation, poor docking effect, and difficulty in meeting the high-efficiency production of large circular knitting machines, and achieve the reduction of local bulkiness and burrs, Keep the effect of the main line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

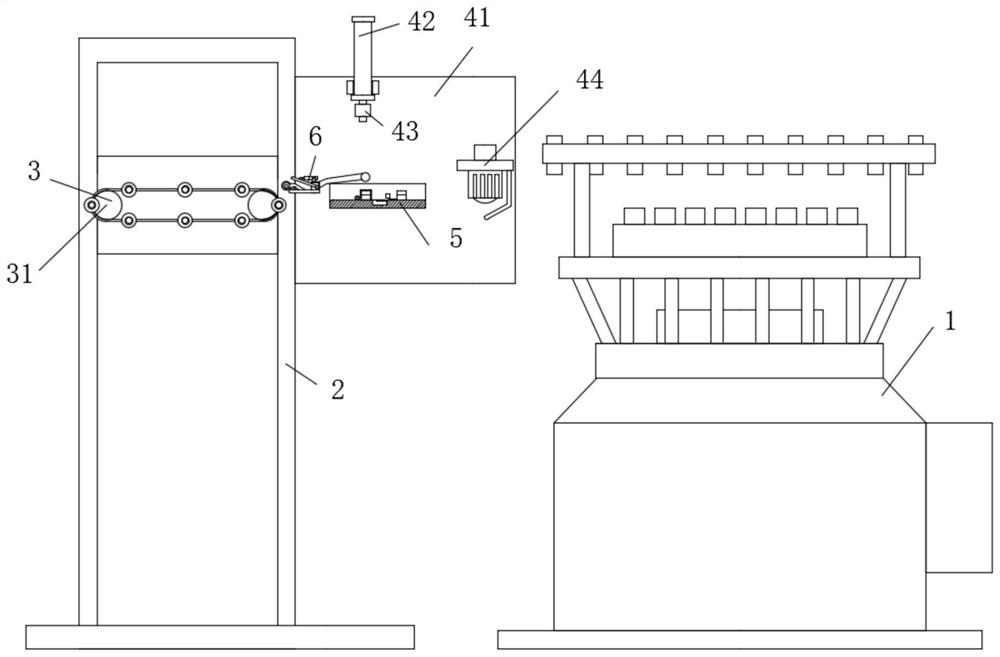

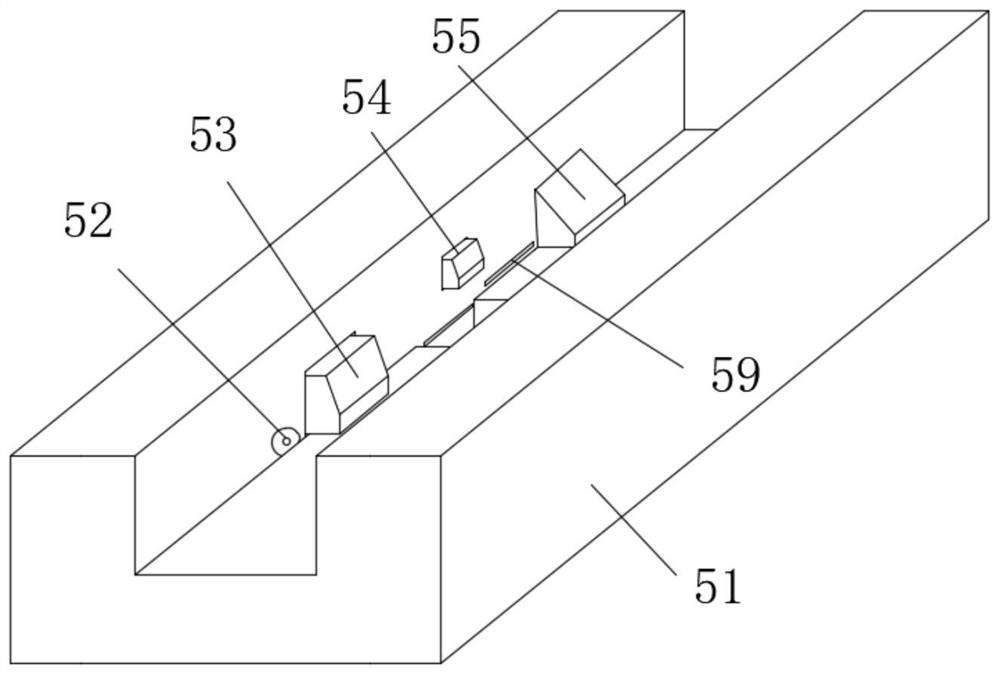

[0027] Example: as Figure 1-7 As shown in the figure, a forming knitting machine for making seamless down jacket fabrics includes a circular knitting machine 1 and a creel 2, a yarn supplying mechanism 3 is arranged inside the creel 2, and a side surface of the creel 2 is provided with a butt joint through a side plate 41. In the mechanism 5 and the clamping mechanism 6, the surface of the side plate 41 is also provided with a cylinder 42 and an ultrasonic bonder 43.

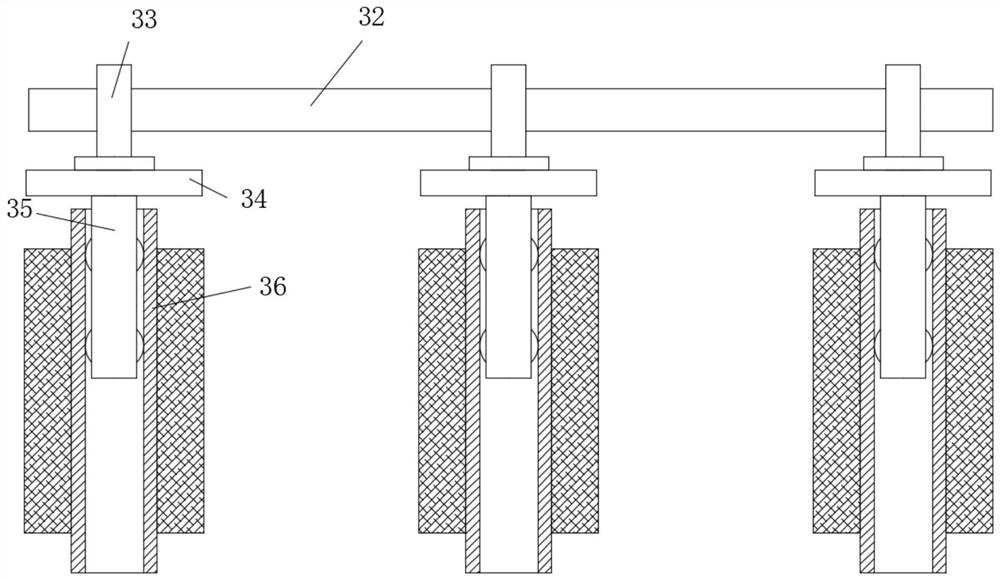

[0028] The yarn supplying mechanism 3 supplies the yarn bobbin 36 cyclically through the driving pulley 31 and the transmission chain 32. The surface of the transmission chain 32 is provided with a fixed rod 33, and the end of the fixed rod 33 is rotatably connected with a rotating member 34. The side surface is provided with a clamping rod 35 for clamping the yarn spool 36. The function of the yarn supplying mechanism 3 is to circulate the yarn spool 36 to the front end of the docking mechanism 5. The yarn spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com