Production equipment and process of bio-based material high-barrier degradable packaging paper

A production equipment and high-barrier technology, applied in the separation of raw materials, papermaking, paper machines, etc., can solve the problems of low pulping efficiency, affecting product quality, affecting production efficiency, etc., to achieve uniform heating, improve pulping efficiency, and improve products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

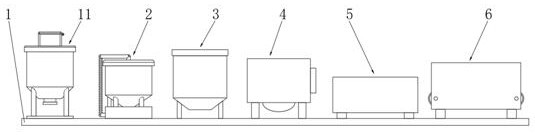

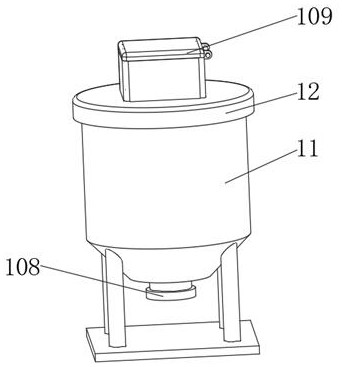

[0033] A bio-based material high-barrier degradable packaging paper production equipment and process, comprising a bottom plate 1, a preparation machine 11, a pulper 2, a pulping machine 3, a pulping machine 4, a paper making machine 5, and a forming machine 6. A preparation machine 11 is provided, a pulper 2 is provided on the bottom plate 1, a pulping machine 3 is provided on the bottom plate 1, a pulp feeder 4 is provided on the bottom plate 1, a paper making machine 5 is provided on the bottom plate 1, and a The molding machine 6 and the pulper 2 include a hydraulic mechanism 8 and a driving mechanism 9 . The hydraulic mechanism 8 is provided inside the pulper 2 , and the driving mechanism 9 is provided within the pulper 2 .

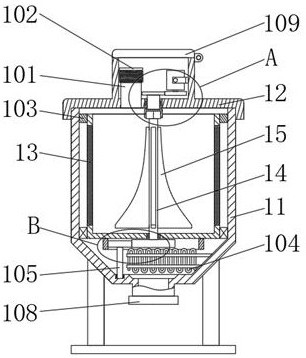

[0034] The preparation machine 11 includes a cover 12 , a filter cartridge 13 , a drive shaft 14 , a stirring blade 15 , a drive seat 16 , a square block 17 , a gear 18 , a servo motor 19 , a gear 2 10 , a telescopic feeding tube 101 , and a tube cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com